Are you tired of sourcing high-lumen bulbs that die within months? Your customers want brighter chandeliers, but pushing the limits in a small bulb often leads to overheating, flickering, and massive product returns that destroy your profits and reputation.

The brightest, most reliable candelabra bulbs deliver a true 800-1000 lumens by balancing high-efficacy LED chips with superior thermal management. Prioritize models with aluminum or ceramic heat sinks and robust internal drivers over all-plastic bulbs that trap heat and are destined for early failure.

The race for the "brightest" bulb is a dangerous one for a product buyer. The laws of physics are unforgiving, especially in a tiny E12 or E14 bulb base. I learned this lesson the hard way alongside a client several years ago. He was an importer for a large US retail chain and was determined to offer a "100-Watt Equivalent" candelabra bulb. He found a factory that promised him a 1200-lumen bulb for a very low price. Against my advice, he placed a huge order. The bulbs were indeed incredibly bright, and they sold well for the first three months. Then, the returns started. First a trickle, then a flood. The bulbs were overheating and dying in fixtures all over the country. The plastic bodies were trapping all the heat, literally cooking the electronics from the inside out. That quest for the highest lumen number on the box cost him his relationship with that retailer. Brightness is important, but brightness without reliability is a liability.

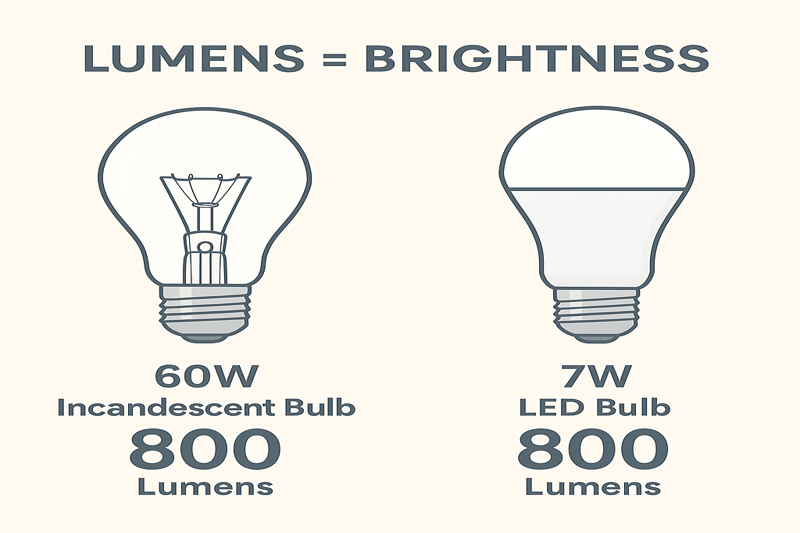

Lumens vs. Watts: What's the real measure of brightness?

Are you still using "watts" to judge the brightness of an LED bulb? This old habit is a common mistake that can lead you to misinterpret a bulb's specifications and choose the wrong product for your customers.

Lumens (lm) are the true measure of a light bulb's brightness. Watts (W) only measure energy consumption. With efficient LEDs, a low-watt bulb can be much brighter than a high-watt bulb from an older technology, making lumens the only reliable comparison.

For decades, we all bought bulbs based on wattage. A 40W bulb was for a small lamp, a 60W was standard, and a 100W was for when you needed a lot of light. This worked because with incandescent technology, there was a direct and predictable relationship between energy used (watts) and light produced. The technology was simple: more watts meant a hotter filament, which in turn meant a brighter glow. LEDs completely changed this. An LED is a highly efficient semiconductor, not a hot wire. It converts a much larger percentage of electricity directly into light, producing very little wasted heat. This efficiency is the magic of LED technology, but it also means that the old rulebook of "watts = brightness" is obsolete. As a manufacturer, our goal is to produce the highest number of lumens using the fewest watts possible. This is called luminous efficacy, and it's the true mark of a well-engineered bulb.

Understanding Luminous Efficacy1 (lm/W)

This is the most important metric for judging a modern bulb's performance.

- Definition: Luminous Efficacy1 is calculated by dividing the total lumen output by the wattage. For example, a bulb that produces 800 lumens and uses 7 watts has an efficacy of approximately 114 lm/W (800 ÷ 7 ≈ 114).

- Why it Matters: A higher efficacy number means you are getting more light for your energy. It is the ultimate indicator of the quality of the LED chips and the efficiency of the internal driver. A cheap, poorly designed bulb might need 10 watts to produce 800 lumens (80 lm/W), while a premium bulb from Hongyu Bulb can produce the same 800 lumens using only 7 watts (114 lm/W).

A Modern Brightness Comparison Chart

Help your customers leave the old wattage mindset behind by using a clear comparison chart. Buyers like Jacky in the US find this kind of tool invaluable because it directly translates the old standard into the new one for their customers.

| Incandescent Wattage Equivalent | Typical Lumen Output (Brightness) | Typical LED Wattage (Energy Used) |

|---|---|---|

| 40-Watt | 450 lumens | 4-5 Watts |

| 60-Watt | 800 lumens | 6-8 Watts |

| 75-Watt | 1100 lumens | 9-11 Watts |

| 100-Watt | 1600 lumens | 12-15 Watts |

When searching for the "brightest" candelabra bulb, you are typically looking for a true 60W to 75W equivalent, which means you should be focused on finding reliable bulbs in the 800 to 1100 lumen range.

Why do most high-lumen candelabra bulbs fail?

Have you ever wondered why that incredibly bright, cheap candelabra bulb stopped working so quickly? The answer isn't a defect; it's a predictable failure of design, and ignoring it is commercial suicide.

The number one killer of high-lumen LEDs is heat. Squeezing powerful electronics into a tiny, unventilated base generates immense heat that degrades the LED chips and destroys the driver. Failure is inevitable without an effective thermal management system (a heat sink).

Every single electronic component, from your phone to a massive server, has a mortal enemy: heat. For an LED, heat is a double-edged sword. Not only does it shorten the lifespan of the chip and the driver's components, but it also actively reduces the bulb's efficiency while it's running—a phenomenon known as "thermal droop." The hotter an LED chip gets, the less light it produces for the same amount of energy. A manufacturer's ability to manage heat is the single greatest indicator of their quality and engineering capability. It is very easy to make a bright bulb. It is very difficult to make a bright bulb that stays bright and continues working for its rated 15,000-hour lifespan. When we design a new high-output candelabra bulb at Hongyu Bulb, the conversation starts with thermal modeling, not with lumens. If we can't get the heat out, we won't build the bulb.

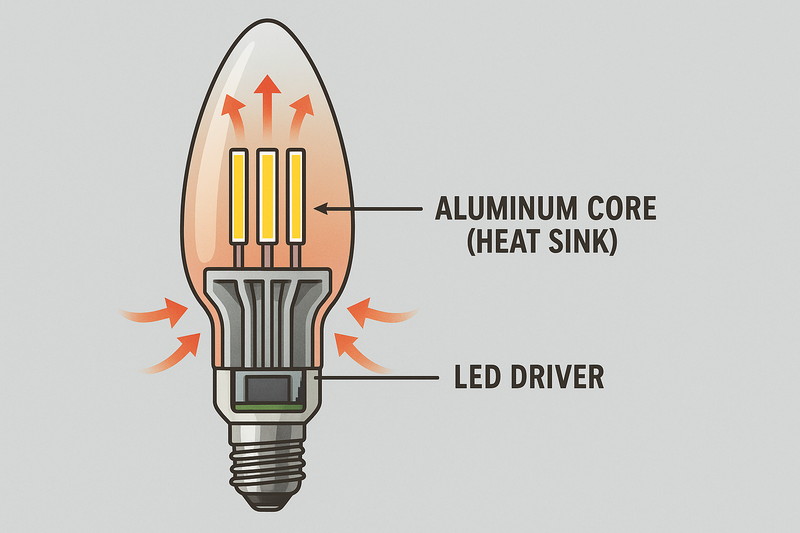

The Science of Thermal Management

You cannot break the laws of thermodynamics. The energy that doesn't become light becomes heat, and that heat must go somewhere.

- Conduction: This is the process of pulling heat away from the source. In a high-quality bulb, the circuit board with the LED chips is mounted directly onto a material with high thermal conductivity2. This is the heat sink.

- Convection: This is the process of dissipating the heat into the surrounding air. The heat sink conducts the heat to the bulb's exterior surface, where air currents can then carry it away.

Materials Matter: The Anatomy of a Heat Sink

The material used to construct the bulb's body is the most critical factor in its survival.

- Bad (Plastic): Standard plastic is a thermal insulator. It traps heat perfectly. An all-plastic bulb, especially one claiming high lumens, is a ticking time bomb. The internal temperature will soar, rapidly aging the components and leading to premature failure.

- Good (Aluminum): Aluminum is a fantastic thermal conductor and is relatively lightweight and inexpensive. The best high-lumen bulbs3 are built with a solid aluminum core or "chassis." This metal structure acts as a highway for heat, pulling it away from the sensitive electronics and dissipating it safely.

- Best (Ceramic): Ceramics are excellent thermal conductors and are also electrical insulators. This makes them a very safe and effective, albeit more expensive, material for heat sinks. They provide a premium look and feel and are exceptionally durable.

Here is a comparison of thermal management strategies:

| Bulb Body Material | Thermal Conductivity | Lifespan Expectation | Typical Application |

|---|---|---|---|

| All-Plastic | Very Poor (Insulator) | Very Short | Low-power, low-lumen decorative bulbs only |

| Plastic-Clad Aluminum | Good | Good (15,000+ hours) | Mid-range to high-performance consumer bulbs |

| Aluminum | Excellent | Excellent (25,000+ hours) | High-performance and commercial-grade bulbs |

| Ceramic | Excellent | Excellent (25,000+ hours) | Premium, specification-grade bulbs |

When a supplier offers you a high-lumen bulb in an all-plastic body, you should see it as a major red flag. They are prioritizing low cost over fundamental engineering principles.

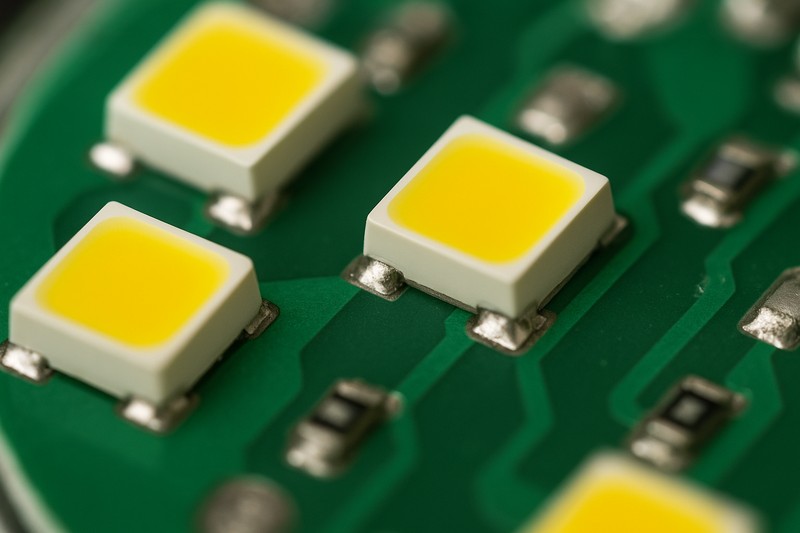

Which LED chip technologies produce the most light?

Do you know what kind of LED is actually inside the bulbs you're buying? The type and quality of the LED chip itself is the starting point for all high-performance lighting.

For high-brightness candelabra bulbs, Surface Mount Device (SMD) chips are the dominant technology. They offer the best combination of high luminous efficacy, excellent thermal contact, and design flexibility needed to pack maximum brightness into a small form factor.

The tiny yellow square that produces the light is the LED chip, and not all chips are created equal. Over the past twenty years, LED technology has evolved at an incredible pace. As a manufacturer, we are constantly evaluating new chips from suppliers to find the ones that offer the best performance in terms of brightness (lumens), efficiency (lm/W), and reliability. For a product manager or buyer, having a basic understanding of the different chip types helps you ask intelligent questions and understand the trade-offs in a bulb's design. While LED filaments are beautiful for decorative, lower-lumen bulbs, and COB (Chip on Board) is great for focused spotlights, SMD technology is the undisputed king for creating the brightest omnidirectional candelabra bulbs.

A Comparison of Common LED Technologies

Let's break down the main types you'll encounter.

- SMD (Surface Mount Device)4: These are individual, square-shaped chips soldered directly onto a circuit board. This direct contact provides a very efficient path for heat to escape into the heat sink, which is critical for high-power applications. Multiple chips can be arranged to create a wide, 360-degree light distribution. This is the workhorse technology for bright bulbs.

- LED Filament5: These consist of multiple tiny LED chips mounted in a series on a clear substrate (like glass or sapphire) and coated in phosphor. They are designed to mimic the appearance of a traditional incandescent filament. While beautiful and very efficient for creating a warm, vintage look, they are difficult to cool effectively at very high power levels, so they typically top out around the 40W-60W equivalent range (450-800 lumens).

- COB (Chip on Board)6: This technology involves mounting a dense array of LED chips directly onto a substrate to form a single, large module. COB is capable of producing a massive amount of light from a very small area, making it ideal for spotlights, downlights, and floodlights where you need a powerful, directional beam. It's less common in candelabra bulbs, which typically require omnidirectional light.

Why SMD is the Choice for High-Lumens

SMD technology offers the perfect balance of features for this specific challenge:

- High Efficacy7: Modern SMD chips regularly exceed 150 lm/W, providing maximum brightness for minimum energy and heat.

- Excellent Thermal Path: Their flat design allows for direct mounting to an aluminum or ceramic circuit board, creating the best possible connection to the heat sink.

- Design Flexibility: We can arrange dozens of small SMD chips in a specific pattern around the bulb's core to precisely control the light distribution, ensuring a smooth, even, omnidirectional glow that illuminates the entire fixture.

This table gives a clear overview for candelabra bulb applications:

| LED Technology | Primary Strength | Lumen Output Potential | Best Application |

|---|---|---|---|

| LED Filament | Vintage Appearance | Low to Medium (up to 800 lm) | Decorative bulbs where looks are key |

| COB (Chip on Board) | High-Intensity Beam | Very High | Directional lighting (spotlights) |

| SMD (Surface Mount Device) | High Efficacy & Heat Management | Medium to Very High (450 - 1600+ lm) | The brightest omnidirectional bulbs |

When sourcing your brightest candelabra bulbs, you should expect them to be built with high-quality SMD chips from reputable brands, mounted on a board that is engineered for heat dissipation.

How does bulb shape and optics affect perceived brightness?

Have you considered that the number of lumens printed on the box doesn't tell the whole story? The shape of the bulb and the finish of the glass dramatically change how that light is delivered, affecting how bright a room actually feels.

A clear, torpedo-shaped bulb will produce the most direct and intense light, creating sparkle and highlights. A frosted (milky) bulb will produce a softer, more diffuse, and more comfortable light by scattering the lumens. The choice depends on the desired effect: sparkle or softness.

Two bulbs can have the exact same 800-lumen output, but they can make a room feel completely different. This is where we move from pure engineering to the art of lighting design. As a supplier, our job is to provide options that allow our clients to achieve different aesthetic goals. The interaction between the light source and the fixture is critical. A chandelier with intricate crystal elements, for example, is designed to sparkle. Using a frosted bulb would be a mistake, as it would deaden the very effect the fixture was designed to create. Conversely, in a fixture with a simple fabric shade or an open sconce, a clear bulb might create harsh glare, whereas a frosted bulb would provide a beautifully soft and even illumination.

Clear Bulbs: The Case for Sparkle and Intensity

A clear glass or plastic envelope allows the light from the LED chips to travel directly outward with minimal interruption.

- Pros:

- Maximum Punch8: Delivers the most intense, focused light.

- Creates Sparkle9: The direct points of light interact with crystal or polished metal elements in a fixture, creating the desired "bling" and visual excitement.

- Higher "Perceived" Brightness: The high contrast and direct glare can make the bulb feel brighter than a frosted counterpart of the same lumen output.

- Cons:

- Can Cause Glare: In an exposed-bulb fixture, the direct view of the bright LED chips can be harsh and uncomfortable on the eyes.

- Creates Sharp Shadows: The direct light source can create hard-edged, distracting shadows in a room.

- Best For: Crystal chandeliers, fixtures with intricate glass elements, any application where creating sparkle and drama is the primary goal.

Frosted Bulbs: The Case for Softness and Comfort

A frosted or milky white envelope contains diffusing particles that scatter the light rays in multiple directions.

- Pros:

- Glare-Free Light10: The diffusion creates a large, soft surface of light, eliminating harsh hot spots and making the bulb comfortable to look at directly.

- Soft, Even Illumination11: It smooths out shadows and provides a more uniform, gentle light throughout a space.

- Conceals the Electronics: It hides the internal yellow LED chips, providing a cleaner, more modern look when the bulb is off.

- Cons:

- Reduces Sparkle: It will not create the a sharp, glittering effect in a crystal chandelier.

- Slight Lumen Loss: The diffusion process absorbs a very small percentage of the light (typically 3-5%), but this is usually imperceptible to the eye.

- Best For: Open fixtures, wall sconces, chandeliers with fabric shades, and any application where comfortable, even, and glare-free illumination is prioritized.

By offering both clear and frosted versions of your brightest bulbs, you give your customers the power to tailor the light to their specific fixture and design aesthetic.

Conclusion

To find the brightest reliable candelabra bulb, ignore watts and focus on high lumens (800+) combined with a quality metal or ceramic heat sink. True brightness is a balance of power and endurance.

Understanding Luminous Efficacy helps you choose energy-efficient bulbs, maximizing light output while minimizing energy costs. ↩ ↩

Understanding thermal conductivity is crucial for selecting effective heat sink materials, ensuring optimal performance and longevity. ↩

Explore the differences in high-lumen bulbs to make informed choices for energy efficiency and lighting quality. ↩

Explore the benefits of SMD technology for efficient lighting solutions and high power applications. ↩

Discover how LED filament bulbs mimic traditional designs while offering energy efficiency and aesthetic appeal. ↩

Learn about COB technology's ability to produce high-intensity light in compact designs, ideal for various lighting needs. ↩

Understand the significance of high efficacy in LED lighting for energy savings and performance. ↩

Explore how Maximum Punch can enhance your lighting design with intense and focused illumination. ↩

Discover the best fixtures that utilize clear bulbs to create stunning sparkle and visual excitement. ↩

Learn about the advantages of glare-free light for creating a comfortable and inviting atmosphere. ↩

Understand the significance of soft, even illumination for achieving a cozy and well-lit environment. ↩