Are your commercial lighting projects plagued by constant bulb replacements? High labor costs, inconsistent lighting, and flickering are frustrating your clients and draining your profits on what should be a simple product.

For commercial spaces, prioritize bulbs with a high Color Rendering Index (CRI 90+), superior flicker-free dimming drivers, and essential safety certifications like UL or ETL. These features ensure longevity, performance, and compliance in high-use environments like hotels and restaurants.

A few years ago, I worked with a project manager who was outfitting a new chain of boutique hotels. He loved the classic, elegant look of chandeliers with dozens of candelabra bulbs. He initially sourced a standard, residential-grade vintage LED bulb because the upfront cost was very low. The installation looked beautiful for the opening. Three months later, he called me in a panic. Nearly 20% of the bulbs were already dead. Others were flickering, and in some hallways, the color of the light from one bulb to the next was noticeably different. His maintenance staff was spending hours every week on scaffolding, replacing bulbs in a 30-foot high lobby. The labor cost completely wiped out any initial savings on the bulbs. This is the crucial difference between residential and commercial lighting: a commercial space is a high-stress, high-performance environment. A bulb isn't just a light source; it's a piece of operational equipment that must be reliable, consistent, and safe, day in and day out.

Why do standard retail bulbs fail so quickly in commercial settings?

Are you constantly replacing bulbs in a restaurant or hotel lobby? The high labor cost of bringing in a lift or scaffolding to change one bulb is often far more than the price of the bulb itself.

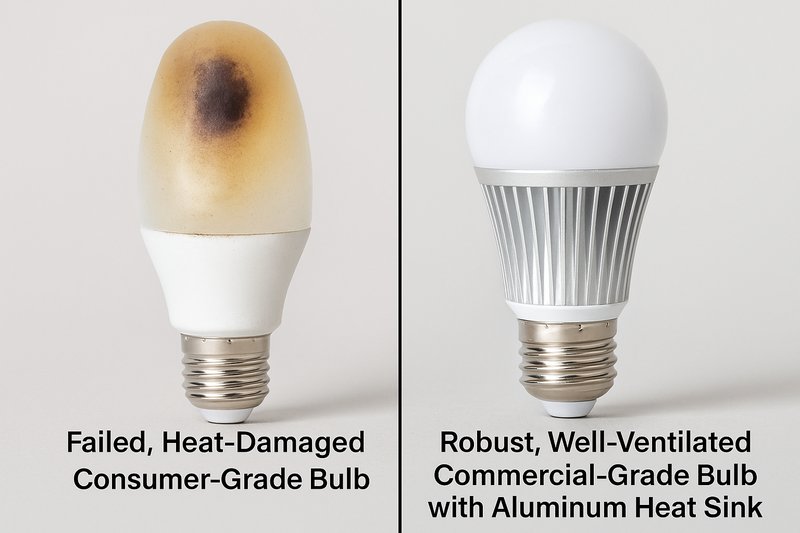

Standard bulbs lack robust thermal management and commercial-grade drivers. The long operating hours (12+ hours/day) and heat buildup in complex fixtures cause their internal temperatures to soar, leading to rapid electronic failure and a drastically shortened lifespan.

The operating environment of a commercial space is brutal on electronics. A bulb in a home might be on for 4-5 hours a day. In a hotel lobby, restaurant, or event hall, it's often on for 12, 16, or even 24 hours straight. This constant "on" state generates a tremendous amount of sustained heat. Residential bulbs are typically built with plastic bodies and minimal heat sinks, designed with the assumption they'll have plenty of time to cool down. In a commercial setting, this design is a recipe for disaster. The internal driver components cook themselves, the LED chips degrade, and the bulb fails. At Hongyu Bulb, when we engineer a bulb for commercial applications, our entire design philosophy shifts. We start with thermal management, using substantial aluminum heat sinks and high-temperature rated components. We know the bulb has to survive, or nothing else matters.

The Critical Role of Thermal Management1

Heat is the number one killer of all LEDs. How a bulb gets rid of it is the primary indicator of its quality.

- Residential Design: Often uses an all-plastic body or a thin "plastic-clad aluminum" shell. This is sufficient for short run-times but acts as an insulator, trapping heat during long commercial operating hours.

- Commercial Design: Utilizes a substantial, solid aluminum or ceramic core. These materials are excellent thermal conductors, acting like a radiator to pull heat away from the sensitive LED chips and driver electronics and dissipate it into the air. This keeps the internal temperature stable, which is the key to a long and reliable life.

The Unseen Hero: The Driver

The driver is the internal power supply for the LED. It's the most common point of failure.

- Standard Drivers: Use lower-cost components (capacitors, resistors) that are not rated for high temperatures or continuous use. They are susceptible to failure from voltage fluctuations common in commercial buildings.

- Commercial-Grade Drivers2: Use high-quality, high-temperature-rated electronic components. They are engineered for stability, efficiency, and longevity under constant load. They are also the key to providing the smooth, flicker-free dimming that is essential in a commercial environment.

Understanding Lumen Depreciation (L70)

It's not just about if the bulb works, but how bright it stays over its lifetime.

- L70 Lifespan3: This is a professional metric that indicates how long it takes for a bulb's light output to decrease to 70% of its initial brightness.

- The Commercial Standard: A cheap bulb might have an L70 of 15,000 hours, but it will lose brightness much faster under commercial stress. A true commercial-grade bulb is tested and rated for its L70 lifespan (e.g., 25,000 or even 50,000 hours) under more rigorous conditions, ensuring the space remains brightly and evenly lit for years, not months.

| Feature | Typical Residential Bulb | True Commercial-Grade Bulb |

|---|---|---|

| Heat Sink | Plastic or minimal aluminum | Solid aluminum or ceramic4 |

| Driver Components | Standard, lower temp rating | High-temperature rated, robust |

| Rated Lifespan | 10,000 - 15,000 hours | 25,000 - 50,000 hours (L70) |

| Typical Daily Use | 3-5 hours | 12-24 hours |

Investing in a bulb designed for the rigors of a commercial setting pays for itself quickly through dramatically reduced maintenance and replacement costs.

How does light quality affect a commercial guest experience?

Does the food in your client's restaurant look dull and unappetizing? Your choice of candelabra bulb could be directly impacting their sales and customer satisfaction.

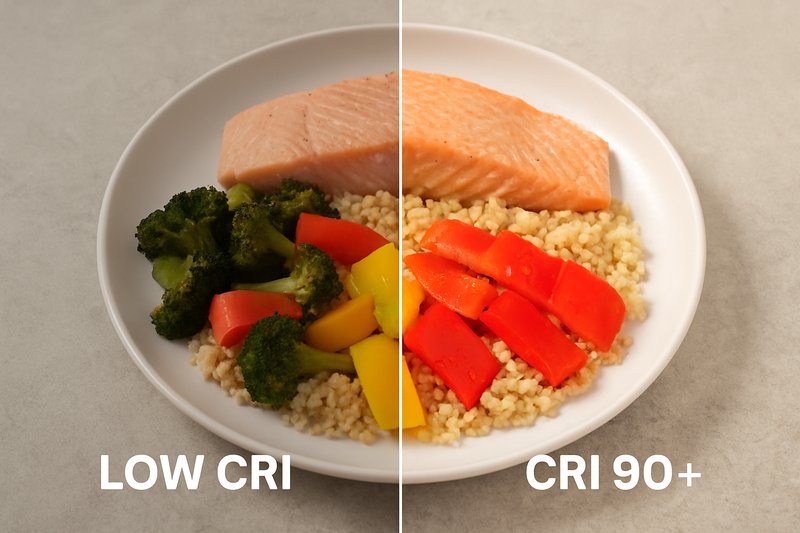

Light quality, measured by the Color Rendering Index (CRI), is critical. A high CRI (90+) ensures that colors appear vibrant and true-to-life. This makes food look delicious, retail products attractive, and interior décor rich, significantly enhancing the guest experience.

Light isn't just for illumination; it's for presentation. In a commercial space, you are always selling something—an experience, a product, a feeling of luxury. The quality of the light is a silent salesman. I once consulted for a high-end retailer who had installed beautiful, custom-made chandeliers. They used cheap LED candelabra bulbs with a low CRI, probably around 75-80. Their expensive leather handbags and silk scarves looked flat and lifeless. We replaced every bulb with a CRI 90+ model from our production line. We didn't change a single fixture, but the transformation was astounding. The colors of the merchandise were suddenly rich and deep, and the entire store felt more luxurious and inviting. Their sales in that department increased in the following quarter. For a buyer like Jacky, being able to explain this concept to his clients is a massive value-add. It moves the conversation from "how cheap is the bulb?" to "how can this bulb make my business more successful?".

Decoding Color Rendering Index (CRI)5

CRI is a scale from 0 to 100 that measures how accurately a light source reveals the true colors of an object compared to a natural light source (like sunlight).

- Low CRI (<80): This is common in cheaper, industrial, or older LED bulbs. Under this light, colors can appear washed out, distorted, or have a strange tint. Reds may look brownish, and blues can look gray. This is completely unacceptable for any hospitality or retail environment.

- Standard CRI (80+): This is the minimum acceptable quality for general residential use. It provides decent color rendering that is perfectly fine for many applications, but it lacks the vibrancy needed for commercial presentation.

- High CRI (90+): This is the commercial gold standard. A CRI of 90 or higher produces light that is very close to natural sunlight. Reds are rich and deep, skin tones look healthy and natural, wood grains are warm, and food looks fresh and appealing. This level of color accuracy is essential for creating a premium atmosphere.

The Importance of Color Consistency (Binning)

In a commercial space with hundreds of bulbs, they must all look identical.

- The Problem: LED manufacturing naturally produces slight variations in color temperature. If these LEDs are not sorted properly, a batch of "2700K" bulbs could contain bulbs that are actually 2650K, 2700K, and 2750K. In a large chandelier, this creates a visually jarring, unprofessional look.

- The Solution: Tight Binning6. High-quality manufacturing, which we pride ourselves on at Hongyu Bulb, involves a process called "binning." We sort the LED chips into very tight tolerance groups (or "bins") based on their exact color temperature. This ensures that every single 2700K bulb we ship looks exactly like every other 2700K bulb. This consistency is a hallmark of a professional-grade product.

| Light Quality Metric | Why It Matters Commercially | Hongyu Bulb Standard |

|---|---|---|

| CRI (Color Rendering Index) | Makes products, food, and décor look vibrant and appealing. | 90+ for all commercial products |

| CCT Consistency7 (Binning) | Ensures all bulbs in an installation look visually identical. | Strict 3-Step MacAdam Ellipse Binning |

| Flicker | Prevents headaches and ensures video/photos look good. | Flicker-free drivers8 (<5% flicker) |

Never compromise on light quality in a commercial setting. It directly impacts your client's brand image and bottom line.

What are the most important safety certifications for commercial bulbs?

Are you sourcing bulbs for a commercial project without checking for UL or ETL listings? This oversight can lead to failed electrical inspections, voided insurance policies, and significant liability risks for you and your client.

UL (Underwriter Laboratories) and ETL (Intertek) listings are the most critical safety certifications in North America. These marks indicate that the bulb has been rigorously tested by a third-party lab to meet strict safety standards for fire and electrical shock, a non-negotiable requirement for most commercial buildings.

This is a topic where there is absolutely no room for error. A product manager for a large U.S. distributor once told me a horror story. He had sourced a container of non-certified LED bulbs for a chain of restaurants to save money. The bulbs worked fine, but when the city's electrical inspector came for the final sign-off on a new restaurant location, he failed the inspection immediately because the lighting products were not UL listed. They had to pay electricians overtime to remove all 500 bulbs and replace them with certified ones, delaying the restaurant's grand opening by a week and costing them tens of thousands of dollars in lost revenue and labor. For any product going into a public or commercial building in the United States or Canada, safety certification from a Nationally Recognized Testing Laboratory (NRTL) is not an option—it's a requirement.

Understanding the Key Certifications

While there are many global certifications, these are the ones that matter most for the North American market that buyers like Jacky serve.

- UL (Underwriter Laboratories)9: This is one of the oldest and most recognized safety certification marks in the US. The UL logo signifies that the product has been tested to their extensive, published standards for safety and has passed.

- ETL (Intertek)10: The ETL mark is another widely accepted certification from an NRTL. It indicates that the product has been tested and complies with the same UL safety standards. For all practical purposes in the eyes of inspectors and insurers, the UL and ETL marks are equivalent.

- RoHS (Restriction of Hazardous Substances)11: This directive originated in the EU but is now a global standard for responsible manufacturing. It restricts the use of specific hazardous materials like lead, mercury, and cadmium in electronics. While not a safety listing in the same way as UL/ETL, it's a critical indicator of a manufacturer's commitment to environmental responsibility and product safety. At Hongyu Bulb, all our products are RoHS compliant.

Why Certification is a Deal-Breaker

The implications of using non-certified products in a commercial space are severe.

- Code Compliance12: The National Electrical Code (NEC) is the benchmark for safe electrical design and installation in the US. Most local building codes are based on the NEC and legally require the use of listed products in commercial and public buildings.

- Insurance Policies13: In the event of a fire or other incident, an insurance company may deny a claim if they discover that non-certified electrical products were a contributing factor. The liability could fall back on the installer, the distributor, or the building owner.

- Quality Assurance14: The process of achieving a UL or ETL listing is rigorous and expensive. It requires a deep dive into the product's design, component selection, and manufacturing processes. A manufacturer who invests in this certification is demonstrating a serious commitment to quality and safety that goes far beyond just the product's performance.

| Certification | What It Certifies | Why It's Essential for Commercial Projects |

|---|---|---|

| UL / ETL | Safety. The product is free from foreseeable risk of fire or electric shock. | Required for electrical code compliance. Essential for passing inspections and for insurance coverage. |

| RoHS | Material Content. The product is free from specified hazardous substances. | Indicates environmental responsibility and a higher standard of manufacturing. Required for import into many regions. |

| FCC | Electromagnetic Interference. The product won't interfere with radio communications. | Prevents issues with Wi-Fi, cell service, or other wireless systems in a commercial building. |

When sourcing for a commercial project, the first question you should ask your supplier is, "Can you provide the UL or ETL file number for this product?" If they can't, you must walk away.

Conclusion

Choosing the right LED candelabra bulb for commercial spaces means prioritizing commercial-grade durability, high-CRI light quality, and non-negotiable safety certifications like UL and ETL to ensure reliability and compliance.

Understanding thermal management is crucial for ensuring LED longevity and performance, making this resource invaluable. ↩

Exploring this topic reveals how high-quality drivers enhance LED efficiency and lifespan, essential for commercial applications. ↩

Learning about L70 Lifespan helps you choose bulbs that maintain brightness over time, ensuring better lighting solutions. ↩

Discovering the advantages of these materials can guide you in selecting durable and efficient LED lighting options. ↩

Understanding CRI is crucial for selecting lighting that enhances color accuracy in various settings. ↩

Tight binning ensures color consistency across LED bulbs, vital for professional-grade lighting in commercial spaces. ↩

CCT consistency is key to achieving a uniform look in lighting, enhancing the overall aesthetic of any space. ↩

Flicker-free drivers improve visual comfort and quality, making them essential for professional lighting solutions. ↩

Explore the importance of UL certification for safety standards in products, ensuring compliance and consumer trust. ↩

Learn about ETL certification and its equivalence to UL, crucial for product safety and market acceptance. ↩

Understand RoHS compliance and its role in promoting environmental responsibility in manufacturing. ↩

Discover the critical role of code compliance in ensuring safety and legality in electrical projects. ↩

Find out how using certified products can impact insurance claims and liability in commercial settings. ↩

Explore how quality assurance through certifications like UL and ETL reflects a manufacturer's commitment to safety. ↩