You've landed a major order for a European client, only to discover at the last minute that your entire inventory of E26 bulbs won't fit their E27 fixtures. This mismatch creates huge logistical nightmares, costly delays, and risks losing the client forever.

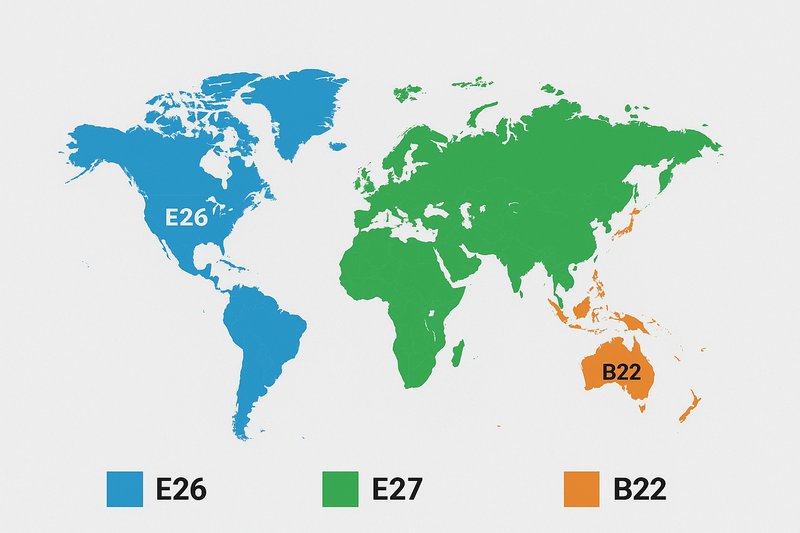

Prevent this disaster by stocking the right base for your primary markets: E26 for North America and Japan, E27 for Europe and most of the world, and B22 for the UK and Commonwealth countries. Understanding these regional standards is non-negotiable for global trade.

Several years ago, I was working with a promising new buyer from the United States. We'll call him Jacky. He was launching an e-commerce brand selling vintage-style lighting fixtures he was sourcing from China, bundled with our beautiful ST64 filament bulbs. His initial orders were small but growing steadily. Then, he decided to expand to the UK market. He placed his largest order yet, but he made a critical oversight: he ordered his entire stock with the standard American E26 base. Two months later, I received a frantic email. His UK warehouse was full of bulbs that wouldn't fit his UK-sourced fixtures. His customers were leaving angry reviews, and his UK launch was turning into a financial disaster. He had assumed, like many do, that a "screw-in bulb" was universal. It was a painful and expensive lesson in the critical importance of that single millimeter difference between an E26 and an E27 base. From that day on, we implemented a pre-order checklist with all our clients, making "Confirm Base Type for Target Market" the number one item. It’s a simple step that has saved our clients millions of dollars in potential losses.

What's the Real Difference Between E26 and E27 Bases?

They look identical, you can often screw an E26 bulb into an E27 socket, and the naming is confusing. So why does this seemingly tiny difference cause such massive problems with electrical safety certifications and international logistics?

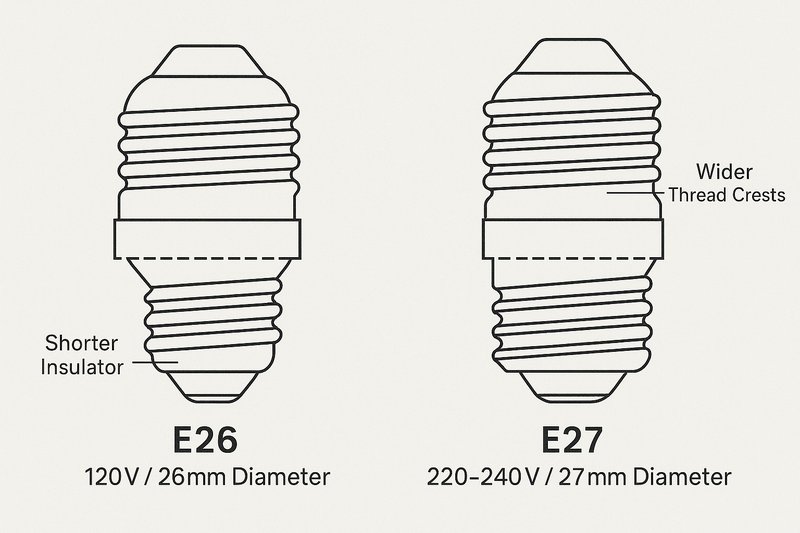

While mechanically similar, E26 and E27 bases are engineered for different regional voltage standards. E26 is for the 120V system in North America, while E27 is for the 220-240V system used in Europe and elsewhere. Using the wrong base can lead to electrical hazards and void safety certifications.

The "E" in E26/E27 stands for Edison, the inventor of the screw base, and the number refers to the diameter of the base in millimeters. An E26 base is 26mm wide, and an E27 is 27mm wide. While that 1mm difference in diameter seems negligible, the more critical differences are in the length of the screw, the height of the electrical contact at the bottom, and the height of the insulator that separates the live contact from the neutral screw shell. These dimensions are specifically defined by international safety standards bodies like UL (Underwriters Laboratories) for North America and IEC (International Electrotechnical Commission) for Europe. The E27 standard requires a greater "creepage distance"—the physical space between the live and neutral contacts—to safely handle the higher 240V potential. While an E26 bulb might physically fit in an E27 socket, the shorter insulator and different thread profile can create a potential arc fault or short-circuit risk at 240V. Conversely, an E27 bulb in an E26 socket may not make proper contact at the base, leading to flickering or failure. For a business, this isn't just a performance issue; it's a legal and safety liability. Importing and selling a bulb with the wrong certification for the region can result in fines, forced recalls, and invalidated business insurance.

The Decisive Factor: Voltage and Certification

This is not a matter of preference; it is a matter of compliance. As a product manager or buyer, this is your ultimate guide.

| Base Type | Nominal Diameter | Designed Voltage1 | Primary Markets | Governing Body / Certification2 |

|---|---|---|---|---|

| E26 | 26 mm | 120 Volts AC | USA, Canada, Japan, Taiwan | UL / cUL |

| E27 | 27 mm | 220 - 240 Volts AC | Europe, UK, Australia, China, Most of Asia & Africa | CE / IEC |

At Hongyu Bulb, we operate separate production lines and maintain distinct inventory for our E26 and E27 products. This ensures that every bulb we ship not only fits the socket but is also fully certified and safe for its intended destination market.

What is a B22 Base and When is it Necessary?

You're preparing a shipment for a large client in the United Kingdom, and they've specified "B22d" bases for all their bulbs. This isn't the familiar Edison screw. What is this different system, and why is it the standard in such a major market?

The B22, or "Bayonet Cap," is a push-and-twist base standard in the UK, Ireland, Australia, India, and other Commonwealth countries. It features two pins on the side of the base that lock into an L-shaped track in the socket.

The "B" in B22 stands for Bayonet, and the number again refers to the 22mm diameter of the base. This system was developed in the UK and became the standard across the former British Empire. Instead of screwing the bulb in, the user pushes the bulb into the socket and gives it a slight clockwise twist. The two pins on the side of the bulb's base slide into corresponding grooves in the socket, locking it firmly in place. The primary advantage of the bayonet system, especially in its early days, was its superior resistance to loosening from vibrations. This made it popular for industrial applications, vehicles, and in homes with heavy foot traffic on the floor above. While the Edison Screw (E27) is also widely used in the UK today, particularly in new fixtures imported from Europe, the B22 base remains extremely common in older homes and is still a required stock item for any business serious about selling into the British, Australian, or Indian markets. The "d" in the full technical name, B22d, simply stands for "double contact," indicating the two pins on the base.

Edison Screw vs. Bayonet Cap: Key Differences

Understanding the functional differences helps you explain the options to your clients and ensure you are sourcing the correct product.

| Feature | Edison Screw (E26/E27)3 | Bayonet Cap (B22)4 |

|---|---|---|

| Installation | Screw in until tight. | Push and twist to lock. |

| Primary Advantage | Simplicity and global ubiquity (outside the UK). | High resistance to vibration. |

| Primary Disadvantage | Can loosen over time with vibration. | More complex to manufacture the lamp holder. |

| Key Markets | E26: North America / E27: Europe & RoW | B22: UK, Australia, India, New Zealand. |

As your manufacturing partner, Hongyu Bulb has extensive experience and dedicated tooling for producing high-quality B22 bases for all our popular filament bulb styles. We make it simple for you to service these important but unique markets without having to find a separate supplier.

How Do You Manage Inventory for Different Global Markets?

You want to sell your lighting products globally, but the prospect of managing separate inventories of E26, E27, and B22 bulbs seems complex and expensive. How can you streamline this process to avoid costly mistakes and logistical headaches?

Implement a market-first inventory strategy. Dedicate separate SKUs for each base type and physically segregate stock destined for North America (E26), Europe (E27), and the UK/Commonwealth (B22). Use clear labeling on all packaging and internal documents to prevent cross-shipping.

This is a challenge we've helped countless clients overcome. The key is to treat bulbs with different bases as completely different products, even if the glass part is identical. The base type must be a primary field in your inventory management system, just like the model number or wattage.

First, create unique SKUs. An ST64 filament bulb with an E26 base should have a different product code than the exact same bulb with an E27 base. For example, ST64-8W-27K-E26 and ST64-8W-27K-E27. This prevents confusion in ordering, receiving, and fulfillment.

Second, enforce clear packaging protocols. The outer cartons and the individual retail boxes must have the base type clearly and prominently printed on them. We work with our clients to design packaging that highlights this, often using a simple check-box system or a bold-type callout.

Third, physically separate your warehouse. As shown in the image, create designated, clearly labeled zones for each base type. This provides a crucial visual check that prevents a warehouse worker from accidentally picking an E26-labeled box from an E27-labeled pallet. It's a simple, low-tech solution that is incredibly effective. Finally, train your sales and logistics teams. Anyone who takes an order or prepares a shipment must be trained to ask the critical question: "What is the destination country?" and to verify the correct base type for that region.

A Pre-Shipment Checklist for Buyers

Before finalizing any large order of light bulbs, use this simple checklist with your supplier to prevent costly errors.

| Check Point | E26 Market (e.g., USA) | E27 Market (e.g., Germany) | B22 Market (e.g., UK) |

|---|---|---|---|

| 1. Confirmed Base Type? | E26 | E27 | B22 |

| 2. Confirmed Voltage? | 110-130V AC | 220-240V AC | 220-240V AC |

| 3. Required Safety Certification5? | UL / cUL | CE / RoHS | CE / RoHS |

| 4. Packaging Clearly Marked6? | "E26 Base" | "E27 Base" | "B22 Base" |

Working with an experienced manufacturer like Hongyu Bulb, who understands these global nuances, is your best insurance policy against making a million-dollar mistake on a one-millimeter difference.

Conclusion

Mastering bulb bases is key to global success. Use E26 for North America, E27 for Europe, and B22 for the UK. This simple knowledge prevents massive logistical failures, ensures safety compliance, and builds international customer trust.

Knowing the significance of designed voltage can prevent electrical hazards and ensure proper product usage. ↩

Understanding certifications helps ensure product safety and compliance, crucial for buyers and managers. ↩

Explore the benefits of Edison Screw bulbs, including their simplicity and global usage, to make informed choices for your lighting needs. ↩

Learn about the advantages of Bayonet Cap bulbs, especially their resistance to vibration, which is crucial for certain applications. ↩

Understanding safety certifications is crucial for compliance and ensuring product quality in various markets. ↩

Clear packaging markings help prevent errors and ensure customers receive the correct product, enhancing satisfaction. ↩