You've invested in a shipment of premium, dimmable LED filament bulbs. But now the complaints are flooding in. Customers are frustrated by flickering, buzzing, and bulbs that fail completely when dimmed, leading to costly returns and damaging your brand's image.

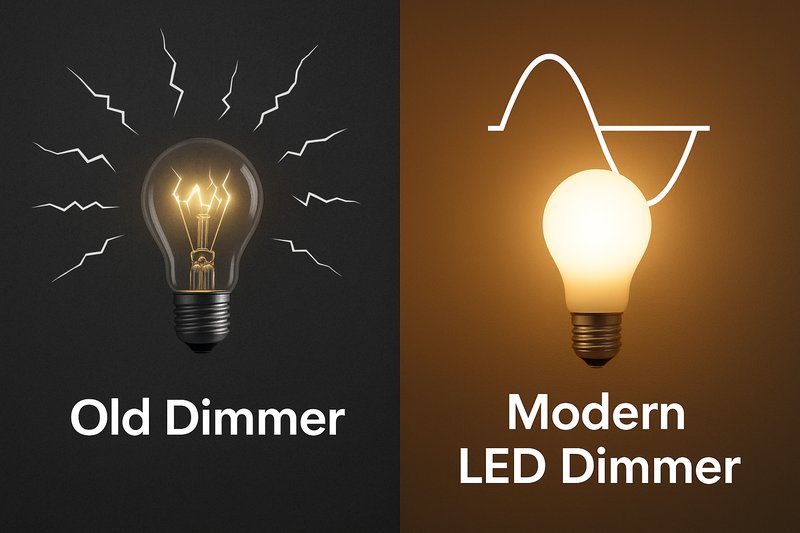

This is almost always caused by an electronic mismatch between the low-wattage LED bulb and an old, high-wattage incandescent dimmer. To ensure smooth, flicker-free performance, you must pair your LED filament bulbs with a modern, LED-compatible trailing-edge or C.L dimmer.

I'll never forget a call I received from a client, Jacky, who had just supplied our top-of-the-line G125 globe filament bulbs for a chain of new high-end cocktail bars in London. It should have been a landmark project for him. Instead, it was a nightmare. "Wallson, the grand opening is in two days, and every light in the place is strobing like a cheap nightclub!" he said, the panic clear in his voice. "The interior designer is threatening to pull our entire contract." I knew the issue wasn't the bulbs; it was something in the installation. I had him send me a photo of the dimmer panel. Sure enough, the electricians had installed heavy-duty, commercial-grade leading-edge dimmers designed to handle massive wattage from old halogen lamps. They were electronic bullies, totally incompatible with our sophisticated, low-wattage LEDs. We had to air-freight a rush order of compatible trailing-edge dimmers from Germany, and his team worked around the clock to replace them. The final bill was enormous, but it saved the project and his reputation. That expensive lesson taught me that being a good supplier isn't just about selling a great bulb; it's about making sure your client understands the entire system to prevent these disasters.

What Really Happens When You Mix Old Dimmers with New LEDs?

You might think "a dimmer is a dimmer," but to an LED bulb, the difference is like night and day. Why does a switch that worked perfectly for 50 years with an old bulb suddenly cause chaos with a new, advanced one?

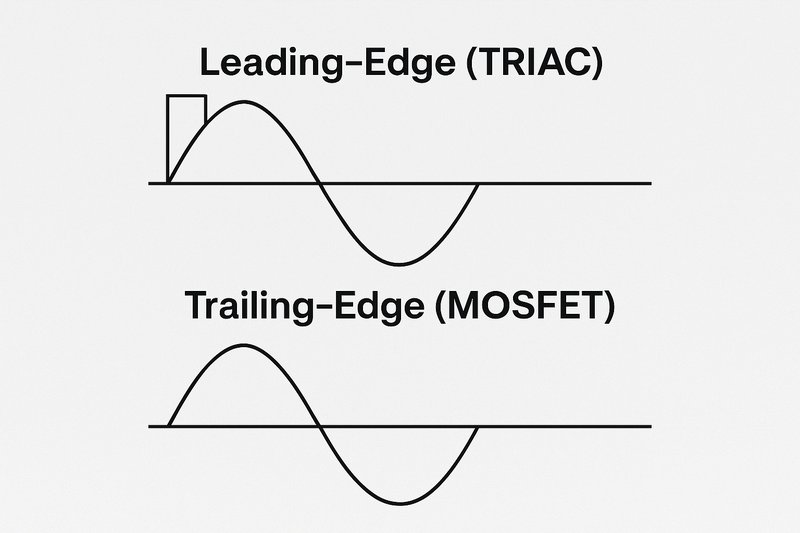

Old leading-edge dimmers are brute-force switches designed for simple, high-wattage incandescent bulbs. They create a harsh electrical signal that confuses the sensitive electronic driver in an LED, causing flicker, noise, and eventual failure. Modern trailing-edge dimmers create a smooth signal that LEDs can understand.

To understand this, you have to think about what these two types of bulbs are. An incandescent bulb is just a piece of wire in a vacuum; it's simple, "dumb" technology. It only cares about raw power. The old dimmers, technically called TRIAC or leading-edge dimmers, work by cutting off the power at the very beginning of each electrical cycle (the AC sine wave). This creates a sudden, sharp jolt of electricity. The simple wire in an incandescent bulb doesn't mind this harsh treatment. An LED bulb, however, is a sophisticated piece of electronics. It has a tiny computer inside its base called a driver, which manages the power for the delicate LEDs. This driver expects a clean, stable electrical signal. When you connect it to an old leading-edge dimmer, that harsh "jolt" of power is like electronic noise. The driver doesn't know how to interpret it, leading to the rapid on-off effect we see as flickering. The buzzing sound you often hear is the physical vibration of components inside the bulb's driver as they struggle with this incompatible signal. This constant stress also dramatically shortens the life of the driver, causing premature bulb failure. Modern, LED-compatible dimmers, known as trailing-edge or reverse-phase dimmers, work differently. They let the electrical cycle start smoothly and then gently cut it off at the end. This "soft-off" approach creates a clean signal that the LED driver can easily interpret, allowing for smooth, silent dimming.

How Can You Spot an LED-Compatible Dimmer in the Wild?

Your customer is in a store or looking at their wall, trying to figure out if their existing dimmer will work or which new one to buy. How can you give them a simple, clear guide to identify the right product and avoid the wrong one?

Look for specific markings on the product or packaging, such as "C.L™," "LED+," "LED/CFL," or a symbol of a diode. Also, check the dimmer's minimum load rating; it must be low, typically 10 watts or less, to work with LEDs.

This is a critical skill for any product manager, installer, or salesperson in the lighting industry. You can't expect every end-user to understand the difference between leading and trailing-edge technology, but you can teach them to look for simple visual cues. The most reliable method is to check the packaging and the device itself for specific compatibility marks. Leading manufacturers like Lutron and Leviton have created their own branding to make this easy. Lutron's "C.L" logo is the gold standard, indicating it's compatible with a wide range of Compact Fluorescent and LED Lamps. Other brands will explicitly state "For use with dimmable LEDs and CFLs" or use similar language. Beyond the branding, the technical specifications are key. On the back of the dimmer or in its instruction sheet, you will find the load ratings. An old incandescent dimmer might say "600W Incandescent." A modern LED dimmer will have a dual rating, something like "600W Incandescent / 150W LED." The much lower wattage rating for LEDs is your first clue. The second, and equally important, clue is the minimum load. An old dimmer might need a minimum of 40 watts to even function. A single 8-watt LED bulb will be below this threshold, causing problems. A good LED dimmer will have a very low minimum load, often 10 watts or even lower, allowing it to work perfectly even with just one bulb.

Quick Identification Checklist

| Clue | Old Incandescent Dimmer (Incompatible)1 | Modern LED Dimmer (Compatible)2 |

|---|---|---|

| Markings | Often has no special markings. May just say "Incandescent." | Marked with "C.L™," "LED+," "LED/CFL," or universal symbols. |

| Max Load Rating | Lists only a single high wattage for incandescent (e.g., 600W). | Has a dual rating: a high one for incandescent, a lower one for LED (e.g., 150W LED). |

| Min Load Rating | High minimum load required (e.g., Min. 40W). | Very low or no minimum load specified (e.g., Min. 5W or "No Min Load"). |

| Physical Type | Often an older-style, push-on/off rotary knob. | Typically a modern slider, paddle, or "smart" digital control. |

How Does Ignoring Dimmer Compatibility Lead to Costly Returns?

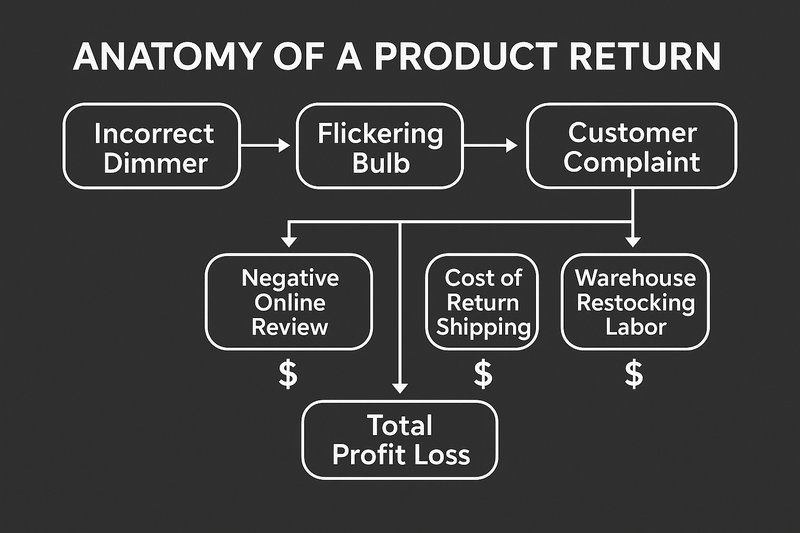

You know there's a technical mismatch, but what is the real-world financial impact on your business when an end-user inevitably pairs your bulbs with the wrong dimmer? The costs go far beyond just the price of the bulb.

Each return triggers a cascade of hidden costs: the loss of the original sale's profit, two-way shipping fees, labor for processing the return, and the immense, unquantifiable cost of a negative online review that can deter hundreds of future customers.

As a product manager or business owner, this is where the technical details translate directly into profit and loss. Let's break down the real anatomy of a single return caused by dimmer incompatibility. First, you lose the profit from the initial sale. That's a direct hit to your revenue. Second, you are almost always expected to pay for the return shipping, and you must also absorb the cost of the original outbound shipping. These logistics costs can easily exceed the value of the bulb itself. Third, you have internal operational costs. Your staff has to spend time communicating with the unhappy customer, issuing a return authorization, receiving the package, inspecting the product (which is likely not defective at all), and processing the refund. This is time they could have spent on productive, revenue-generating activities. But the most significant cost is the damage to your brand's reputation. A frustrated customer is far more likely to leave a one-star review than a happy customer is to leave a five-star one. That negative review, stating "These expensive bulbs flickered and died in a week - JUNK!", will live on your product page forever. It poisons the well for future buyers, creating doubt and friction in the sales process. A single technical oversight can create a public-facing mark of poor quality that costs you far more in lost future sales than the initial return ever could.

Hypothetical Cost Analysis of a Single Return

| Cost Component | Example Value | Impact on Business |

|---|---|---|

| Original Bulb Price | $15.00 | Revenue lost from initial sale. |

| Cost of Goods Sold | -$6.00 | Direct product cost. |

| Gross Profit Lost | $9.00 | Initial profit wiped out. |

| Outbound Shipping | -$5.00 | Unrecoverable logistics expense. |

| Return Shipping Label | -$5.00 | Additional logistics expense. |

| Labor (Customer Service/Warehouse) | -$7.50 (30 min @ $15/hr) | Hidden operational overhead. |

| Total Tangible Loss3 | $26.50 | Cash out of your pocket on a single $15 bulb. |

| Intangible Loss4 | 1 Negative Review | Erodes trust and deters countless future buyers. |

Multiplying this by hundreds of returns reveals a catastrophic, yet entirely preventable, financial leak.

Conclusion

Dimmer compatibility isn't a minor detail; it's the key to performance, customer satisfaction, and profitability. By insisting on modern LED dimmers, you prevent flickering, protect your bulbs from failure, and safeguard your brand's reputation for quality.

Learn why Old Incandescent Dimmers can cause issues with LED lighting and how to avoid them. ↩

Explore the advantages of Modern LED Dimmers for energy efficiency and compatibility with LED lights. ↩

Understanding total tangible loss helps businesses identify financial leaks and improve profitability. ↩

Exploring intangible loss reveals its significant impact on customer trust and long-term business success. ↩