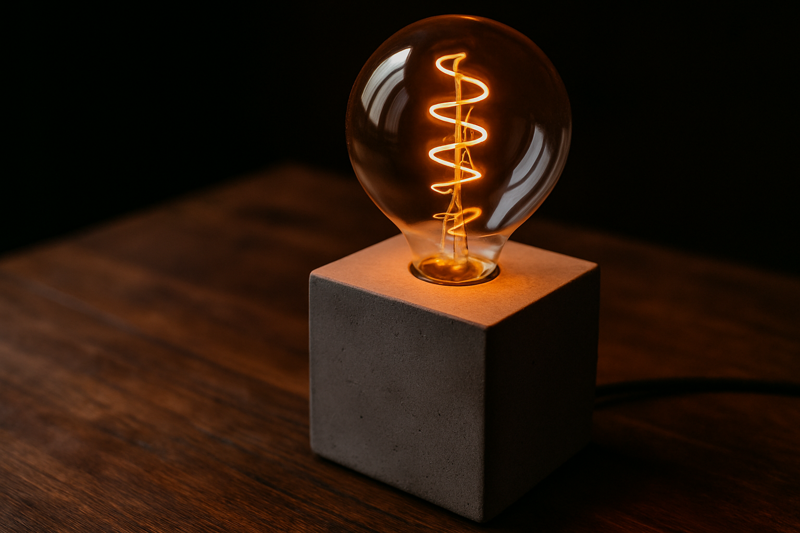

You spend weeks sourcing the perfect rusted iron pipes, heavy concrete bases, and vintage fabric cables. But when you turn the lamp on, the magic dies because the light is stark white and flat.

The soul of an industrial lamp is not the metal body; it is the visible filament. To successfully sell industrial lighting, you must pair your raw fixtures with LED filament bulbs that replicate the warm, complex glow of 1920s tungsten, while meeting modern energy regulations.

I remember walking through a trade show in Guangzhou last year with a buyer named Jacky from the US. He was looking at a supplier selling "Steampunk" fixtures. They were heavy, well-made, and expensive. But the supplier had installed cheap, frosted plastic bulbs in them. Jacky shook his head and walked away. "Wallson," he said, "It looks like a toy." He was right. Industrial style is about honesty. It is about showing the mechanics of the object. If you hide the light source behind white plastic, you destroy the aesthetic. At Hongyu Bulb, we understand that for this specific design trend, the bulb is 50% of the product. B2B buyers often focus so much on the fixture tooling that they forget the engine.

Why Do Heavy Metal Fixtures Need Delicate Glass Hearts?

Industrial design is often cold, hard, and masculine, using materials like black iron and grey concrete. Without the right balance, these lamps can feel like unfinished construction material rather than home decor.

You need contrast. The warm, organic curves of a "Soft Filament" LED bulb soften the harsh lines of metal piping and concrete. This "Hard Shell, Soft Center" approach creates a cozy emotional connection that makes the product sellable for residential living rooms.

When you are manufacturing or importing industrial lamps, you are essentially selling a contradiction. The customer implies they want a "factory" look, but they actually want a "cozy home" feel.

If you use a bulb with straight, rigid LED sticks inside a rigid square metal cage, the result is aggressive. It looks like a prison light.

However, if you use what we call "Soft Filament" (flexible LED strips), the psychological effect changes. The filament looks like a glowing noodle or a handwritten signature. It bends and flows.

The Physics of the Contrast

This works on a visual level because of material opposition:

- The Base: Opaque, matte, heavy, cold colors (Black, Grey, Rust).

- The Bulb: Transparent, glossy, light, warm colors (Gold, Amber).

From a manufacturing perspective, using LED filaments offers a hidden advantage: Heat Safety1.

Real industrial factory lights in the 1920s got incredibly hottest. If you touched the metal cage, you would burn your hand. This is a liability lawsuit waiting to happen in the modern US market.

Because Hongyu LED filaments run cool (converting 90% of energy to light, not heat), the metal fixture remains cool to the touch. You can sell a heavy iron pipe lamp to a family with children, and they don't have to worry about safety.

Furthermore, the lack of heat preserves the finish of your lamp. High heat from old bulbs creates "thermal cycling2" which can cause the paint on your metal pipes to crack or peel over time. LED preserves your product quality.

Material Matching Table

| Fixture Material | Recommended Bulb Shape | Visual Effect |

|---|---|---|

| Black Iron Pipe | ST64 (Teardrop) | Classic 1920s "Edison" factory look. |

| Grey Concrete | G125 (Large Globe) | The round bulb breaks the square blockiness. |

| Polished Brass | A60 (Standard) | The brass acts as a mirror; keep the bulb simple. |

| Reclaimed Wood | T30 (Tubular) | The long line mirrors the grain of the wood. |

Why Is the ST64 Shape the Undisputed King of Industrial Design?

You look at every bestseller list on Amazon for "Vintage Lamps," and one specific bulb shape appears again and again. You might wonder if you should try something different to be unique.

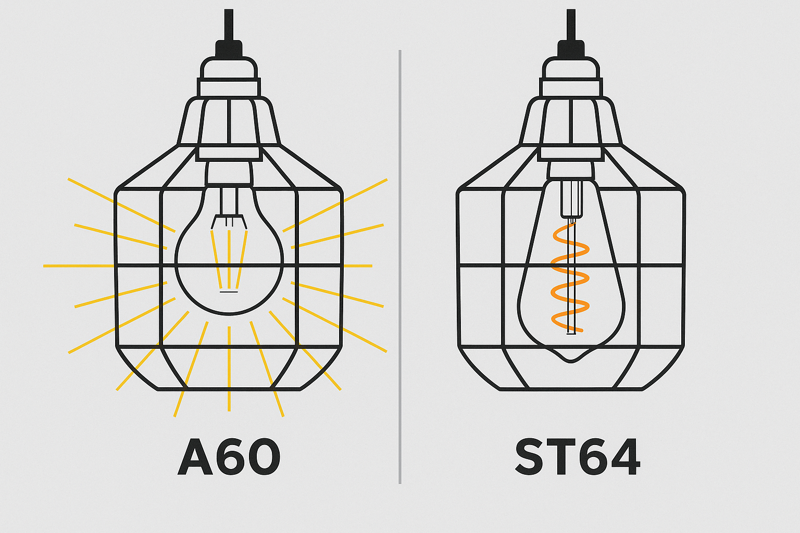

Do not fight the classic. The ST64 (Straight Tube 64mm), also known as the "Teardrop" or "Edison" shape, is the standard for a reason: its elongated neck keeps the filament visible even when the bulb is seated deep inside a socket or a wire cage.

In the B2B world, we sometimes get bored selling the same things. It is tempting to buy the new, weird shapes. But regarding Industrial Style, the ST64 is the anchor.

The "ST" stands for Straight Tube (though it bulges at the top), and the "64" is the diameter in millimeters.

Why is this specific shape so crucial for industrial lamps? It comes down to the Socket Cup.

The Socket Problem

Most industrial lamps use heavy metal sockets—brass, aluminum, or Bakelite. These sockets are often deep.

- The Problem: If you screw a standard round A60 (household) bulb into a deep industrial socket, half of the bulb disappears into the cup. You lose light, and it looks stubby and awkward.

- The Solution: The ST643 has a tapered neck that extends about 2-3cm before the glass widens. This pushes the glowing filament out of the socket and into the open air.

The Cage Problem

Industrial lamps often feature "Wire Guards4" or cages. These cages are designed based on vintage specifications.

A round bulb (G80 or G95) acts like a balloon—it is physically too wide to fit inside many standard metal cages. The ST64 is slender. It slides perfectly into the clamp-style cages used on pendant lights.

Jacky, my US client, once tried to save money by importing "Industrial Kits" that came with standard G45 round bulbs. He had to recall them because customers could not fit the cages over the bulbs. He learned the hard way. Always stick to the ST64 for caged fixtures.

At Hongyu Bulb, we produce the ST64 with a "Golden Tint" glass as standard for this market. The clear glass looks too modern. The gold tint mimics the aged glass of a bulb that has been burning in a factory for 50 years.

How Do You Stop Your Minimalist Lamp from Blinding the Customer?

Industrial design often involves "Exposed" bulbs—no fabric shade, no frosted glass. The bulb is naked. If you use a regular brightness bulb, it will be painful to look at.

Brightness control is the difference between "Mood Lighting" and "Interrogation Lighting." For exposed industrial lamps, you must use lower lumen outputs (under 400 lumens) or darker glass tints to ensure the filament is visually distinct and comfortable to view directly.

Customers often ask me for "High Power" bulbs. In the industrial sector, this is a mistake.

If a bulb is 800 lumens (60W equivalent), and it has no shade, it will create glare. The human eye cannot handle looking at a point-source of light that bright. The iris closes, and the room actually feels darker because the contrast is too high.

If you are selling a "Desktop Pipe Lamp," it sits right next to the user's face. If that bulb is too bright, they will turn it off and never use it again.

The "Smoke" and "Amber" Solution

There are two ways we engineer bulbs to solve this for our B2B partners:

- Lower Lumen Driver: We intentionally program the driver to deliver less current. We offer 4W bulbs that only emit 200 or 300 lumens. This is "Decorative Power." It is enough to read a menu or create atmosphere, but not enough to hurt the eye.

- Glass Tinting:

- Amber/Gold: This cuts the blue light spectrum. It makes the light feel warmer (2200K) and reduces the perceived sharpness of the glare. It creates a "sunset" effect.

- Smoke/Grey: This is becoming very popular for "Modern Industrial" styles (think loft apartments). The glass is coated in a translucent grey mirror finish. When the bulb is off, it looks like a sleek piece of black metal or chrome, matching the lamp base. When it is on, the filament glows through the grey glass, looking mysterious and dim.

The "Smoke" and "Amber" Solution

There are two ways we engineer bulbs to solve this for our B2B partners:

- Lower Lumen Driver: We intentionally program the driver to deliver less current. We offer 4W bulbs that only emit 200 or 300 lumens. This is "Decorative Power." It is enough to read a menu or create atmosphere, but not enough to hurt the eye.

- Glass Tinting:

- Amber/Gold5: This cuts the blue light spectrum. It makes the light feel warmer (2200K) and reduces the perceived sharpness of the glare. It creates a "sunset" effect.

- Smoke/Grey6: This is becoming very popular for "Modern Industrial" styles (think loft apartments). The glass is coated in a translucent grey mirror finish. When the bulb is off, it looks like a sleek piece of black metal or chrome, matching the lamp base. When it is on, the filament glows through the grey glass, looking mysterious and dim.

Consumer Education on Lumens

You must educate your buyer (and they must educate the end consumer).

If the packaging says "400 Lumens," a regular customer might think "This is weak."

You need to label it as "Accent Decor Light" or "Vintage Atmosphere."

We can print custom packaging for you that clearly explains: Designed for Exposed Bulb Fixtures - Low Glare.

Glare Management Table

| Application | Bulb Distance from Eye | Recommended Lumens | Glass Tint |

|---|---|---|---|

| Desk Lamp | 0.5 meter | 150 - 250lm | Heavy Amber / Smoke |

| Dining Pendant | 1.5 meter | 300 - 450lm | Light Amber |

| Ceiling Cluster | 3.0 meters | 600 - 800lm | Clear / Light Amber |

Can Tangled Wires Be Considered High Design?

One of the cheapest yet most visually striking industrial trends is the "Spider Chandelier." It is just wire, sockets, and bulbs. But if the bulbs don't match perfectly, it looks like a mess.

The "Spider" look relies entirely on repetition and consistency. Because the fixture is minimal, any variation in the light color (CCT) or brightness between the 6, 8, or 10 bulbs becomes obvious. You need strict "Binning Control" from your manufacturer to ensure perfect uniformity.

This is a specific favorite of my B2B clients because the shipping volume is tiny. A spider chandelier is just a bunch of wires. It fits in a small box. But on the ceiling, it covers 2 square meters. It is high value, low shipping cost.

However, the challenge is Consistency.

Since there are no shades, the bulbs are the main character. If you buy cheap bulbs from a generic market, the 3rd bulb might be slightly pinker than the 4th bulb. The 5th bulb might be slightly brighter.

When you have 10 bulbs hanging next to each other, these small differences look terrible. It screams "Low Quality."

The "Binning" Process at Hongyu

At our factory in Dongguan, we use a process called MacAdam Ellipse Binning7.

When we produce LED chips, there is naturally some variation in color.

For our Industrial Series, we sort the chips strictly. We ensure that every bulb in a single batch falls within a "3-step MacAdam Ellipse."

This means the human eye cannot see the difference between Bulb A and Bulb B.

When a restaurant owner buys a 12-head spider light, they need all 12 heads to match.

Furthermore, for these suspended lights, the Filament Design8 matters.

You should recommend Long Filaments (like in the ST64 or T30).

Why? Because the bulb is hanging vertically.

A short filament at the bottom of the bulb looks sad.

A long filament that stretches from the bottom to the top fills the glass and creates a "Column of Light." This mimics the look of the wire hanging down.

Suspension Aesthetic Tips

- The Knot: Encourage customers to tie knots in the fabric cable. This adds to the "improvised" industrial look.

- The Mix: Some designers mix shapes (ST64 + G95 + A60) on one spider. This is risky. If you do this, the filament color (Kelvin) must be identical, or it looks disjointed.

- The Socket: Use aluminum or bakelite sockets with visible switches. The "Click" of a rotary switch on the socket adds tactile value.

Is Your "Vintage" Light Too Blue to Be Believed?

You screw in an LED bulb. It is bright, efficient, and saves money. But it makes your rustic wood table look like a frantic hospital operating room.

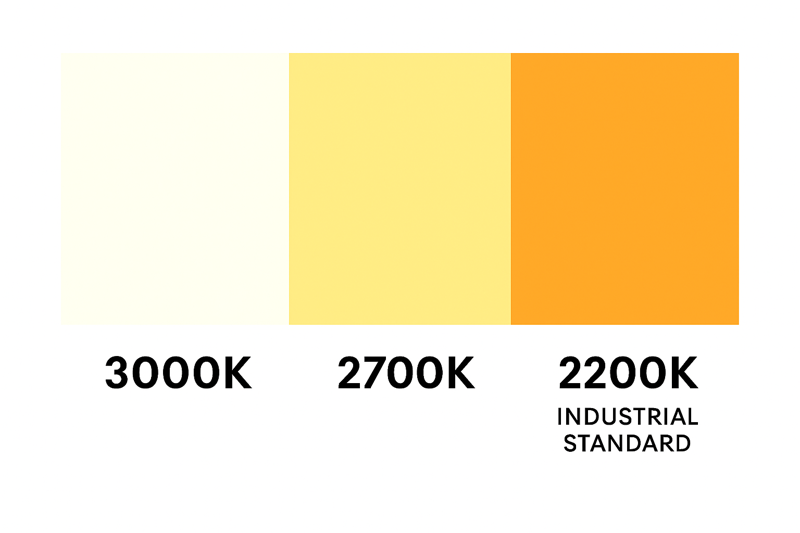

Industrial style is fueled by nostalgia, and nostalgia is warm. You must avoid the standard 2700K or 3000K "Warm White." True industrial aesthetics demand 2200K "Candlelight" or even 2000K to replicate the carbon filaments of the Victorian era.

I have fights with engineers about this all the time. Engineers want "Efficiency."

They say, "Wallson, if we make the light 2200K, we lose lumen efficiency. It is not bright enough!"

I tell them, "The customer does not buy this bulb to read a textbook. They buy it to drink whiskey."

The color temperature (CCT) is the emotional trigger.

- 3000K: Use this for an office or a kitchen workspace. It is functional.

- 2700K: This is the standard for living rooms. But for true "Industrial," it is still a bit too clean.

- 2200K: This is the sweet spot. It looks like a flame. It turns wood rich and deep. It makes skin look healthy. It makes brass sparkle.

The "Red Phosphor" Secret

Buying a 2200K bulb is not simple.

Cheap factories achieve 2200K by just painting the glass orange.

Inside, they use a blue LED chip.

The result is a greenish, muddy light that looks orange on the outside but casts a weird shadow.

High-quality Hongyu bulbs use Red Phosphor on the LED filament strip itself.

This means the light source is actually generating warm red/orange wavelengths.

The difference is the CRI (Color Rendering Index).

The painted glass bulb creates dull colors (CRI < 70).

The Phosphor bulb creates rich colors (CRI > 90).

If you are selling lamps to high-end hotels or restaurants, they will notice this immediately. Their expensive food and furniture will look dead under the cheap painted bulbs.

CCT Selection for Industrial Vibe

| Bulb CCT | Appearance | Best Use Case |

|---|---|---|

| 5000K | Daylight / Blue | NEVER. Do not use for decoration. |

| 3000K | Bright White | Workshops, Garages (Functional Industrial). |

| 2700K | Soft White | General room lighting, overhead fixtures. |

| 2200K | Golden / Amber | Exposed bulbs, Pipe lamps, Moody corners. |

| 2000K | Deep Orange | Nightlights, Decorative accents, "Fire" effect. |

Conclusion

Industrial lighting is a marriage of rugged materials and vintage atmosphere. By choosing the correct LED filament bulbs—specifically emphasizing the ST64 shape, warm 2200K color temperature, and low-glare options—you transform a pile of metal piping into a high-value design piece that captures the nostalgic heart of your customer.

Explore this link to understand how LED lighting enhances safety by reducing heat, making it ideal for homes with children. ↩

Learn about thermal cycling and its impact on light fixtures to ensure your products maintain their quality over time. ↩

Discover how the ST64 bulb enhances lighting in industrial settings, solving common socket issues and improving aesthetics. ↩

Learn about Wire Guards and their role in vintage lamp designs, ensuring safety and style in industrial lighting. ↩

Explore how Amber/Gold tinting enhances ambiance and reduces glare, making it ideal for creating warm, inviting spaces. ↩

Discover the aesthetic appeal and modern style of Smoke/Grey tinting, perfect for contemporary interiors. ↩

Understanding MacAdam Ellipse Binning can enhance your knowledge of LED color consistency and quality, crucial for lighting design. ↩

Exploring Filament Design will provide insights into creating visually appealing lighting solutions that enhance ambiance. ↩