You spend thousands on complex light fixtures that collect dust and are hard to install. Your minimalist customers want bold design without the visual clutter of shades and frames. You need a lighting solution that acts as furniture.

Oversized LED Edison bulbs—specifically the "Giant" series like PS160, BT180, and A165—act as standalone sculptural pieces that eliminate the need for lampshades. Their massive glass dimensions and intricate internal filament structures turn a simple hanging cord into a high-value lighting statement.

Lighting trends are moving toward "Less is More."

But "Less" does not mean "Small."

It means fewer components, but bigger impact.

Ten years ago, a chandelier had fifty crystal pieces and ten small candle bulbs.

Today, a chandelier is often just one massive piece of glass glowing softly.

This is the Oversized Bulb category.

I call them the "Giants."

Technically, any bulb with a diameter over 125mm falls into this group. Some of them are as big as a watermelon.

If you walk into a trendy coffee shop in New York or London, you see them.

They hang low over the tables.

They are not there to light up the room. They are there to define the space.

For a B2B buyer, this category is scary but profitable.

It is scary because shipping big glass is risky.

It is profitable because the perceived value is huge. A customer will pay $50 or $80 for one of these bulbs because it replaces a $200 lamp.

Which Giant Shape Fits Your Specific Interior Style Best?

The shape of the glass changes the personality of the room entirely. A round globe feels modern and soft, while a jagged or tubular shape feels industrial and aggressive. You must stock the correct silhouettes for your target market.

The three pillars of oversized lighting are the PS160 (a massive teardrop for vintage warmth), the BT180 (a large tube for industrial lofts), and the G200 (a giant sphere for modern minimalism). Choosing the right shape ensures the bulb compliments the furniture below it rather than clashing with it.

When I meet clients at the Canton Fair, they look at the wall of Giant bulbs and get confused.

There are so many weird shapes. Alien shapes.

But you only need to focus on the classics to make money.

Let me break down the geometry for you.

The Organic Pear: PS160

The code PS stands for "Pear Shape." The 160 is the diameter in millimeters (16cm).

This is the big brother of the standard ST64 Edison bulb.

It looks like a drop of water falling.

This is my best-selling giant bulb.

Why? Because it feels natural.

The curve at the bottom is wide, and it tapers up to the neck.

It fits perfectly in "Rustic1" or "Farmhouse" interiors. My client Jacky sells these to restaurants that have a lot of wood and brick. The curves of the bulb match the organic feeling of the wood.

The Industrial Tube: BT180

BT means "Bulbous Tube."

This thing looks like a tool or a heavy glass bottle.

It is tall and slightly aggressive.

It hangs vertically.

This shape is strictly for "Industrial" styles.

Think of a loft with concrete floors and metal beams.

A round bulb looks too soft there. The BT180 has straight lines and strong shoulders.

It creates a column of light.

If your customer is designing a bachelor pad or a steakhouse, this is the bulb to pitch.

The Modern Sphere: G150 / G200

We talked about globes before, but the G200 (20cm wide) is different.

It is a planet.

When you hang a G200, it dominates the room.

This is for "Modern" and "Scandi" styles. White walls, simple furniture.

Because it is a perfect circle, it brings a sense of Zen and order.

However, be careful. A sphere this big reflects everything. If the glass has a single wave or bubble, it looks terrible.

Table: Size and Application

| Code | Shape Description | Diameter / Height | Best Application | Vibe |

|---|---|---|---|---|

| PS160 | Giant Tear Drop | 160mm / 290mm | Dining Tables | Vintage, Romantic |

| BT180 | Large Bottle / Tube | 180mm / 350mm | Stairwells, Corners | Tough, Industrial |

| G200 | Massive Sphere | 200mm / 200mm | Center of Room | Clean, Minimalist |

Does a Small Filament Ruin the Aesthetics of a Giant Bulb?

A massive glass envelope with a tiny standard filament in the center looks ridiculous and cheap. The light source must fill the volume of the glass to create a cohesive look.

Oversized bulbs require lengthened vertical filaments or complex spiral designs supported by a central glass pillar to ensure the light source occupies the entire visual cavity. Use spiral filaments to create a glowing sculpture effect, or long pillar-mounted LED sticks to mimic high-power architectural lamps.

Design is about proportion.

Imagine a large empty mansion with only one small chair in the middle. It looks sad.

That is what happens if you put a standard A60 filament inside a PS160 bulb.

There is too much empty air.

The customer is paying for the glass, but they are also buying the "glow."

The internal structure must match the external size.

The Central Glass Pillar

Standard bulbs have a short stem at the bottom.

Giant bulbs need a backbone.

We extend a glass rod2 from the base all the way to the top of the bulb.

This is expensive to make. It requires a skilled glassblower (or a very advanced machine).

This pillar does two things:

- Support: It holds the filament up. Without it, a long filament would wobble and break during shipping.

- Aesthetics: It allows us to mount the LEDs high up in the center of the sphere, not just at the bottom.

When I inspect our production line, I check if the pillar is straight. If the pillar is crooked, the whole bulb looks broken.

The Art of the Spiral

For Giant bulbs, the Flexible Spiral Filament3 is the king.

We can wind it around the central pillar.

It looks like a vine growing up a tree.

Because the bulb is big, we can make the spiral lose and wide.

This creates a very complex light pattern.

When the light shines through the thick curved glass of a PS160, it refracts.

It creates lines of light on the wall.

Straight filaments do not do this as well.

Straight filaments in a giant bulb look like a cage. Spiral filaments look like a cloud.

The Brightness Challenge

You have to be careful here.

A giant bulb suggests "Giant Power."

But usually, these are decorative. We run them at 4W or 6W.

Why? Because of heat and glare.

If we made a 20W giant bulb, it would get too hot (no heat sink), and it would blind everyone.

The goal is to make the filament look big, but keep the power low.

We do this by running the LEDs at a lower current.

This makes the spiral glow gently, rather than burning brightly.

I always tell Jacky: "Sell these as 'Ambient Lighting4', not 'Task Lighting'." If a customer wants to read under a PS160, they will be disappointed. It is mood lighting.

| Internal Design | Structure | Visual Effect | Cost |

|---|---|---|---|

| Short Sticks | No Pillar | Empty, Cheap, Unbalanced | Low |

| Long Vertical | With Glass Pillar | Architectural, Strong Lines | Medium |

| Wide Spiral | With Glass Pillar | Artistic, Volumetric Glow | High |

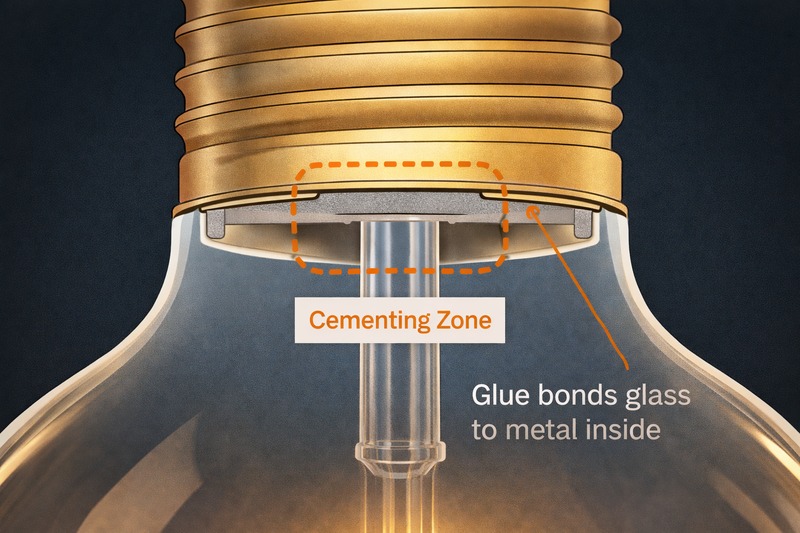

How Do We Prevent the Heavy Glass from Separating from the Base?

These bulbs are heavy. Gravity is constantly pulling the massive glass body away from the small metal cap. If the glue fails, the glass falls and shatters, leaving a live socket exposed.

The "Torque Test" and the quality of the base cement are critical for oversized bulbs because the glass weight can exceed 300-500 grams. We use deep-skirted brass bases and high-grade distinct cement to increase the bonding surface area, ensuring the bulb can hang safely for years.

Safety is not sexy, but it keeps you out of court.

A standard light bulb weighs 30 grams.

A Giant PS160 can weigh 300 to 500 grams.

That is half a kilogram of glass hanging over someone's head.

Held by glue.

This is the most common failure point I see in cheap oversized bulbs.

The Cement Problem

The glue we use is called "Base Cement." It is a powder mixed with alcohol.

When it cures, it becomes like stone.

In a standard bulb, we put a little ring of cement in the cap.

For a Giant bulb, that is not enough.

If the factory tries to save money on cement, or if they cure it too fast in the oven, it becomes brittle.

Six months later, the customer walks into the room, and SMASH.

The glass falls. The metal cap stays in the socket.

This is a disaster.

The Deep Base Solution

We do not use standard E26/E27 caps for Giants.

We use "Deep Caps5."

The metal skirt is longer.

This gives us more surface area to apply the glue.

More surface area = stronger bond.

Also, we often add "indentations" or dimples to the metal cap to grip the cement better.

The Torque Test6

Before we ship to the USA, we do a Torque Test.

We screw the bulb into a holder.

Then we twist the glass with a specific amount of force (Measured in Newton-meters).

If the glass spins inside the cap, it fails.

We also do a "Pull Test." We hang a weight from the glass to see if it pulls out of the cap.

Jacky once bought a batch from a trader (not me) because they were $1 cheaper.

He had to recall all of them because the glass was loose.

Buying cheap Giants is buying a lawsuit.

| Feature | Standard Bulb | Giant Bulb Requirement | Reason |

|---|---|---|---|

| Cap Height | Standard | Extended / Deep | Increases glue contact area. |

| Cement Type | Standard | High-Adhesion Heavy Duty | Supports extra weight. |

| Testing | Basic Light Up | Torque + Pull Test | Ensures gravity won't win. |

Is Shipping "Air" Killing Your Profit Margins?

Oversized bulbs are mostly empty space inside a fragile glass shell. Shipping them is expensive because carriers charge by volume, not weight. You need a packaging strategy that minimizes volume while maximizing protection.

The logistics of oversized bulbs require a balance between volume weight and breakage protection. We use custom-molded pulp trays or high-density foam that nests the bulbs in an alternating pattern (head-to-tail) to reduce box size, but importers must calculate the landed cost carefully.

Here is the headache of the B2B buyer: Dimensional Weight.

A container costs $5,000 (roughly).

If you fill it with Giant bulbs, you are mostly shipping air from China to America.

The bulbs are light, but the boxes are huge.

The Packaging Dilemma

You have two choices:

- Styrofoam (EPS): It is the safest. It offers the best cushion. But it is bulky. And in Europe, it is becoming illegal due to environmental laws.

- Paper Pulp: It is eco-friendly. It stacks better (nests). But it is less bouncy.

For Giant bulbs, we often have to use Styrofoam for safety, even if it hurts the environment slightly.

Or, we use a very thick, high-grade corrugated paper box (Kraft paper).

We suspend the bulb inside the box so it touches nothing.

The "Head-to-Toe" Packing

To save money on shipping, we cannot pack them all standing up in a grid.

We pack them nicely interlocked.

One bulb points up. The next points down.

This creates a tighter pack.

We can fit 20% more bulbs in a container this way.

20% more product means 20% more profit for equal shipping cost.

The Breakage Allowance7

No matter how good the packing is, FedEx and UPS will break things.

When you buy Giant bulbs from China, you must negotiate a "Breakage Allowance."

I usually give Jacky a 1% or 2% spare rate.

For every 100 bulbs, I give him 2 free ones.

Or, I credit him for any breakage.

But the packaging design is key.

Never buy oversized bulbs in a soft "Color Box."

They need a "Mail Order Box" (MOB).

This is a brown box that can survive a 1-meter drop test.

If you put a Giant bulb in a thin retail shelf box, it will never survive the journey from your warehouse to the customer's house.

| Pkg Method | Safety Level | Volume Efficiency | Eco-Friendly | Cost |

|---|---|---|---|---|

| Thin Color Box | Low (High risk) | High | Yes | Low |

| Styrofoam | High | Low (Bulky) | No | Medium |

| Reinforced Pulp | Medium/High | Medium | Yes | High |

| Double Box | Maximum | Very Low | Varies | Very High |

Conclusion

Oversized LED bulbs are powerful design tools that offer high margins by replacing entire light fixtures. However, their success depends on mastering the physical challenges: selecting strong spiral filaments that fill the void, ensuring robust base cement to fight gravity, and optimizing packaging to make the logistics profitable.

Explore this link to discover how Rustic lighting can enhance your home’s charm and warmth. ↩

Find out how a glass rod supports and enhances the design of bulbs, ensuring both functionality and beauty. ↩

Explore this link to understand how the Flexible Spiral Filament enhances lighting aesthetics and functionality. ↩

Discover the nuances of ambient lighting and why it's ideal for creating mood in spaces. ↩

Explore this link to understand how Deep Caps enhance the strength and reliability of lighting fixtures. ↩

Learn about the Torque Test to see how it ensures the safety and durability of lighting products. ↩

Understanding Breakage Allowance is crucial for managing shipping costs and ensuring product safety during transit. ↩