You install stylish vintage bulbs in a client's ceiling fan, only to see them flicker or die within weeks. Returns damage your reputation and eat your profits.

LED Edison bulbs for ceiling fans must be "Vibration Resistant" and specifically sized (usually A15 or small A19) to fit restricted housings. A spinning fan creates constant micro-tremors that break standard filaments, so you must select bulbs with reinforced internal supports and enclosed-fixture ratings.

Most buyers assume a light socket is just a socket, but a ceiling fan is a hostile environment for electronics due to movement and heat.

Do Standard Filament Bulbs Fail Faster in Ceiling Fans?

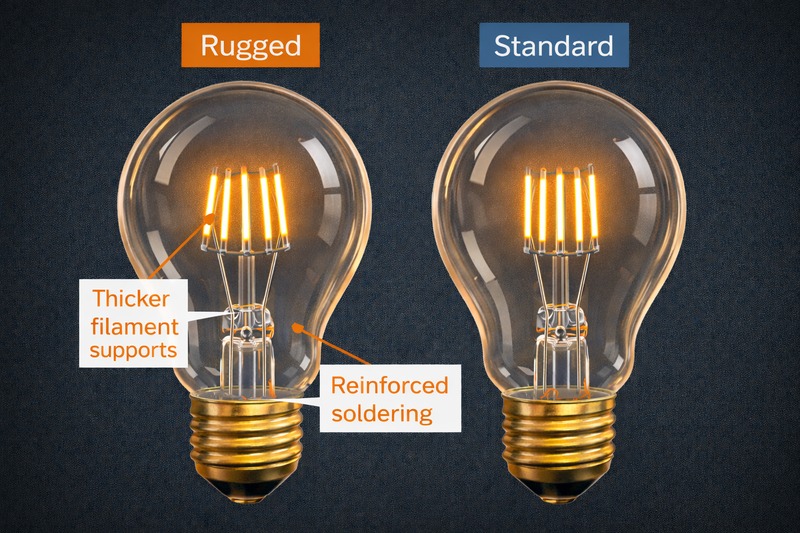

Standard vintage bulbs use long, fragile LED sticks that wobble when the fan spins. This movement causes early failure that cheap suppliers never mention.

The constant vibration of a motor destabilizes long LED filaments and cracks weak solder joints on the driver board. For longevity, choose bulbs with shorter filaments (like A15s) or specific "Fan Rated" bulbs that use extra support posts and high-temperature solder to withstand the shaking.

I have seen this happen a hundred times. Jacky called me last summer screaming that a batch of ST64 bulbs was "dead on arrival." We investigated. The bulbs worked in table lamps but died in ceiling fans. The culprit was vibration from the motor. A ceiling fan is never perfectly balanced, and it always wobbles slightly. Inside a cheap Edison bulb, the LED filament is held by a thin metal wire.

The Tuning Fork Effect

If the filament is long (like in a large vintage bulb), it acts like a tuning fork. When the fan spins, the filament shakes. Eventually, the tiny gold wire connection inside snaps, and the light divides. Furthermore, the heavy driver board in the base can vibrate loose if the glue is weak.

The Manufacturing Solution

We solve this for B2B buyers in three ways. First, we reinforce the structure. We add an extra "anchor" point to the filament in our Fan Series. This stops the swaying. Second, we focus on compact designs. Generally, smaller bulbs (A15, G45) have shorter filaments. Shorter means stiffer. Stiffer means less vibration damage. Third, we improve the solder. We use a flexible silver-alloy solder that can absorb small movements without cracking. Standard tin solder is brittle. If you sell lighting for homes, you must label your bulbs "Vibration Resistant1" if they are meant for fans.

| Component | Standard Bulb | Fan Rated Bulb | Benefit |

|---|---|---|---|

| Filament Support | Single anchor | Double/Reinforced anchor | Prevents wobbling. |

| Solder Type | Brittle Tin | Flexible Silver Alloy2 | Resists cracking. |

| Driver Glue | Standard epoxy | High-temp Silicone | Absorbs vibration. |

Which Bulb Shape Fits Best in Restricted Fan Fixtures?

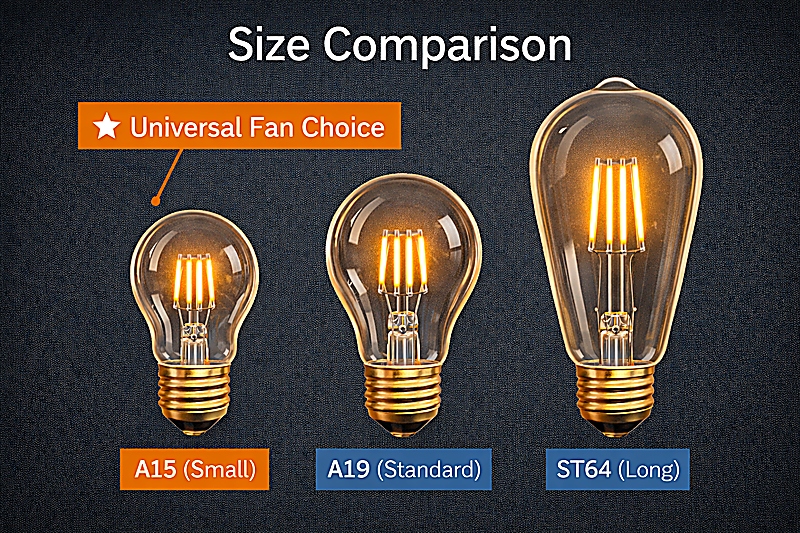

Ordering the wrong size bulb is a logistical nightmare. Ceiling fans usually have small glass shades or cages that cannot accommodate standard bulb necks.

The A15 (Appliance Bulb) is the industry standard for ceiling fans because its small 45mm diameter fits inside almost any glass shade. However, for open-cage "farmhouse" fans, the ST58 or ST64 (Teardrop) is preferred for aesthetics, provided the cage is long enough to cover the glass tip.

Style is important, but physics is non-negotiable. Most ceiling fans sold in Home Depot or Lowe's use "Light Kits." These kits often have small glass cups (globes) to cover the bulbs. An A19 bulb (the standard household size) is often too tall. It sticks out looking ugly, or worse, it pushes against the glass.

The Heat Trap Problem

If an LED bulb touches the glass shade, it cannot cool down. The heat builds up and kills the driver. The A15 (G45)3 is the little hero of the fan world. It is short and stubby. It fits everywhere. However, for the trendy "Industrial" fans that use wire cages instead of glass cups, the A15 looks too small. It looks like a toy. For those, you need the ST58 (The slightly smaller version of ST64). It has that pear shape everyone loves, but it is compact enough not to hit the cage bars.

Watch Your Bases

Also, watch out for the socket size. In the US, older fans use E12 (Candelabra) tiny screw bases to save space. Newer fans use E26 (Medium) bases4. I always advise Jacky to sell "Fan Bundles"—a pack of bulbs specifically chosen to fit the most common fan fixtures, clearly labeled with the base size. This prevents the customer from forcing a large bulb into a small hole.

| Bulb Code | Common Name | Fit Risk | Best For |

|---|---|---|---|

| A15 / G45 | Fan/Appliance | Low (Fits all) | Glass Bowl Shades |

| A19 / A60 | Standard | Medium (Too tall?) | Large Bowl Fans |

| ST58 | Short Edison | Medium | Wire Cage Fans |

| ST64 | Tall Edison | High (Hits cage) | Exposed Socket Fans |

Why Do LED Bulbs Flicker or Glow When the Fan is Off?

Modern fans use electronic remotes that leak small amounts of current. This causes efficient LEDs to strobe or "ghost" even when the switch is off.

Many ceiling fan remotes use solid-state switches that never fully cut the power, causing sensitive LED filaments to flicker or glow faintly (ghosting). You must source bulbs with high-quality drivers that include a "bleeder resistor" to absorb this leakage current and ensure the light stays completely off.

This is the number one technical complaint I receive from the US market. The customer installs the bulb. They turn the fan light OFF with the remote. But when they go to sleep, they see a faint orange glow coming from the bulb. It is spooky. They think the house is haunted. It is not a ghost. It is "Current Leakage."

The Technical Reality

Old ceiling fans used mechanical switches (chains). Click on, click off. Complete separation. Modern fans use smart remotes. These remotes require a tiny bit of power to stay "alive" and listen for the signal. They pull this power through the lighting circuit. Incandescent bulbs were inefficient, so this tiny current didn't light them up. LEDs are so efficient that this tiny "leakage" current is enough to light them up slightly, or charge the capacitor until it flashes (flicker).

The "Bleeder" Solution

We have to install a "Dummy Load" or "Bleeder Resistor5" on the driver board inside the bulb base. This component eats the leakage current so it doesn't reach the LED chips. Cheap bulbs do not have this. When I manufacture bulbs specifically for "Fan Applications," I always use the upgraded driver. It costs $0.05 more, but it prevents the "Ghost Light6" return. You must test your bulbs with Lutron and Hunter fan controllers. If you skip this, you will suffer.

| Symptom | Cause | The Fix |

|---|---|---|

| Ghosting (Glow when off) | Leakage current from remote. | Driver with Bleeder Resistor. |

| Strobing (Flash every few sec) | Capacitor charging/discharging. | Compatible Dimming Driver. |

| Buzzing Noise | PWM Dimming interference. | Silent/Noise-canceling Inductor. |

Conclusion

Ceiling fans are bulb killers due to vibration and electrical leakage from remotes. To serve this market, stop selling standard bulbs; stock reinforced A15 or ST58 LEDs with anti-ghosting drivers to ensure your customers get a light that stays steady and lasts longer.

Understanding 'Vibration Resistant' can help you choose the right bulbs for fan applications, ensuring durability and performance. ↩

Exploring the advantages of Flexible Silver Alloy can enhance your knowledge of soldering techniques and improve product quality. ↩

Explore the advantages of A15 (G45) bulbs for fans, including their compact size and versatility in various fixtures. ↩

Learn about E26 (Medium) bases, their compatibility with modern fixtures, and why they are essential for efficient lighting. ↩

Understanding Bleeder Resistors can help you prevent issues like ghost lighting in LED bulbs. ↩

Exploring the causes of Ghost Light can help you troubleshoot and improve your lighting setup. ↩