You want the flexibility of track lighting but despise the clinical, cold look of standard spotlights. Your clients demand the warmth of vintage Edison bulbs, but mixing these two technologies often leads to poor lighting and burned-out components.

Yes, you can use LED Edison bulbs in track lighting, but only if you use "Open Socket" or "Skeleton" track heads. Standard cylinder track heads trap heat and kill the bulb's electronics. Furthermore, because Edison bulbs are omnidirectional, they will wash the room with light rather than spotting specific artwork, changing the function of the track entirely.

Most people think track lighting is strictly for galleries or retail displays.

They imagine bright white beams hitting a painting.

But the definition of track lighting is changing.

It is no longer just for highlighting objects. It is now a flexible power source for decorative lighting.

Designers are ripping out old halogen cans and installing tracks.

Then, they want to screw in a vintage ST64 or Globe bulb to make the space feel cozy.

Jacky, my buyer from the US, tried this last year in a cafe project.

He put 300 classic bulbs inside deep canister track heads.

Two months later, 50% of them were dead.

Why? Because he treated a decorative bulb like a directional spotlight.

To succeed here, you must understand the war between Heat, Optics, and Old Dimmers.

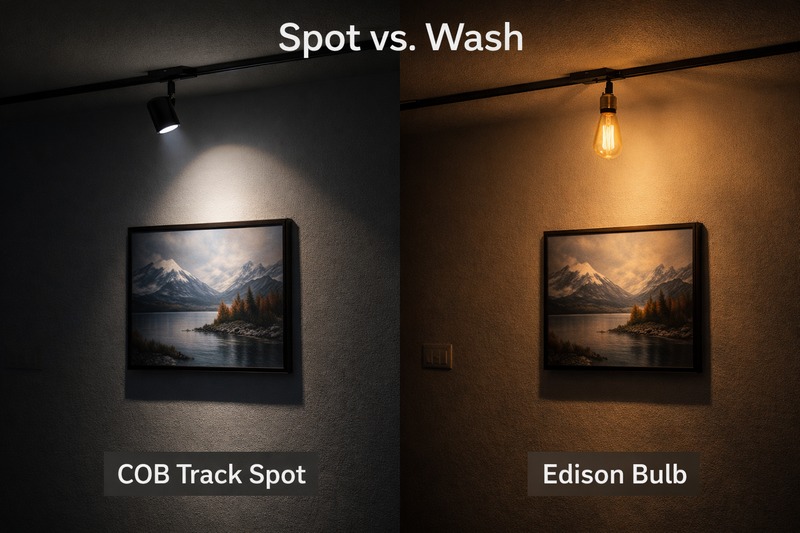

Do Edison Bulbs Defeat the Purpose of Directional Lighting?

Track lighting exists to point light at specific things, but Edison bulbs throw light in every direction. If you put a filament bulb on a track, you lose control of the beam, creating a general "glow" instead of a focal point.

Standard LED Edison bulbs have a 360-degree beam angle, making them ineffective for spotlighting artwork or retail displays. To use them effectively on a track, you must change the goal from "Accent Lighting" to "Ambient Task Lighting," or utilize specialized "Half-Chrome" bulbs that reflect light backward to reduce glare.

When you look at a traditional track light bulb, like a PAR30 or lighter GU10, you see a lens.

That lens grabs the light and pushes it forward in a tight cone. Maybe 24 degrees or 36 degrees.

An Edison bulb does the opposite.

It is a glass bubble. The filaments stand vertically. The light shoots out sideways, backwards, and forwards.

If your customer wants to highlight a menu on a wall, an Edison bulb is the wrong tool. It will light up the floor, the ceiling, and the customer's eyes, but the menu will look dim.

The Application Shift

However, this "flaw" is actually a benefit for general room lighting.

In a kitchen with a single junction box, a track system with Edison bulbs can light the whole room.

A standard spotlight track leaves dark shadows in the corners.

An Edison track fills the room with soft, warm light.

You must train your sales team to ask: "Do you want to see the Bulb, or do you want to see the Object?"

If they want to see the object, sell them a directional lamp.

If they want the bulb to be the furniture, sell them the Edison.

The Half-Chrome1 Solution

There is a hybrid trick.

We manufacture "Half-Chrome" or "Silver Bowl" filament bulbs (A19 or G25 shapes).

We paint the top half of the glass with a mirror finish.

When you put this on a track head, the mirror blocks the light from hitting the user's eyes directly.

It reflects the light back toward the ceiling or the fixture.

This reduces the painful glare that happens when you look up at a track system.

It creates a sophisticated, indirect lighting effect.

It keeps the vintage look but solves the glare problem.

| Bulb Type | Beam Angle | Track Use Case | Glare Level |

|---|---|---|---|

| COB Spot (PAR/BR) | 15°-60° | Highlighting Art/Retail | Low (Controlled) |

| Standard Edison | 360° | General Room Ambience | High (Direct eye contact) |

| Half-Chrome Edison | 180° (Reflected) | Decorative/Indirect | Medium (Shielded) |

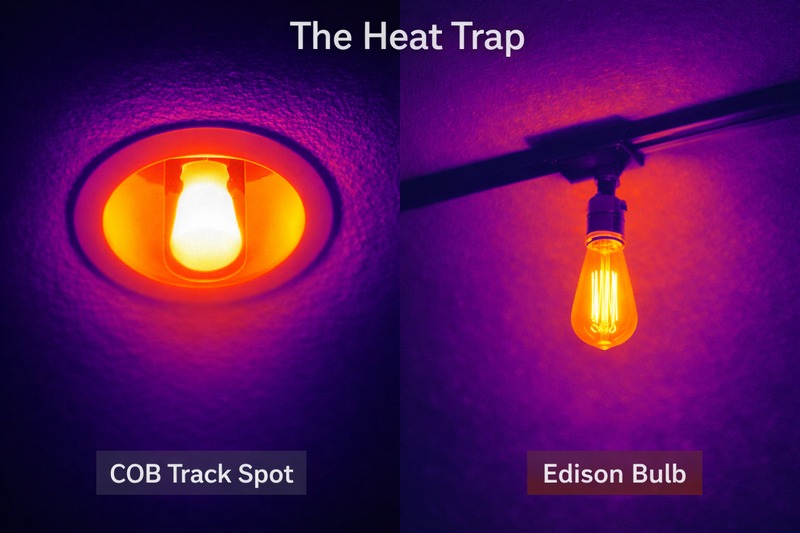

Why Do Bulbs Burn Out Faster in Cylinder Track Heads?

Aesthetics often drive buyers to choose sleek, deep cylinder heads to hide the "ugly" base of the bulb. This design choice creates a lethal heat trap that cooks the sensitive driver components inside the LED base.

LED drivers are extremely sensitive to heat and require passive airflow to function; placing an Edison bulb inside a deep metal canister blocks convection cooling. You must recommend "Open Cage," "Gimbal Ring," or simple "Socket Adapter" track heads that expose the bulb's neck to the air.

Heat is the silent killer of all LEDs.

But for Edison bulbs, it is worse because the driver is jammed into a tiny metal cap (E26 base).

There is no heavy aluminum heat sink with fins like you see on a PAR30 bulb.

The heat sink is the gas inside the glass and the air around the base.

The Cylinder Effect

Designers love "Canister" track heads. They look clean. They look like pipes.

They shove the entire bulb inside so only the glass face shows.

When you do this with a filament bulb, you create an oven.

The heat rises from the LED filaments. It gets trapped in the top of the can (the "back" of the fixture).

The base of the bulb—where the electronic driver lives—sits exactly in this hot zone.

Capacitors inside the driver are rated for maybe 105°C.

Inside a canister track head, the temperature can easily hit 120°C after 4 hours.

The electrolyte liquid inside the capacitor evaporates. The bulb starts flickering or just dies.

I tell Jacky: "If you sell canisters, do not sell my Edison bulbs2. Use PAR bulbs."

The "Skeleton" Head Solution

To use Edison bulbs safely, the air must touch the neck of the bulb.

We recommend "Skeleton" heads.

These are just a simple socket on a swivel arm. No shade. No cup.

Or "Wire Cage" heads.

These allow 100% airflow.

The bulb runs 30 degrees cooler.

This doubles the lifespan.

If the customer insists on a shade, it must have vent holes in the back.

But frankly, if they are buying an Edison bulb, they usually want to see the naked bulb.

Hiding it inside a can makes no sense aesthetically or technically.

Technical Failure Rates

In my factory testing:

- Bulb A (Open Air): 5% failure rate at 15,000 hours.

- Bulb B (Enclosed Canister): 50% failure rate at 2,000 hours.

You cannot warrant a bulb that is installed in a toaster. You must educate the buyer on the fixture choice.

| Fixture Style | Airflow | Edison Bulb Suitability | Risk Level |

|---|---|---|---|

| Deep Tube/Canister | None (Trapped) | Do Not Use | Extreme |

| Shallow Cone | Moderate | Okay for low Wattage | Medium |

| Wire Cage | High | Excellent | Low |

| Bared Socket | Maximum | Best Performance | Lowest |

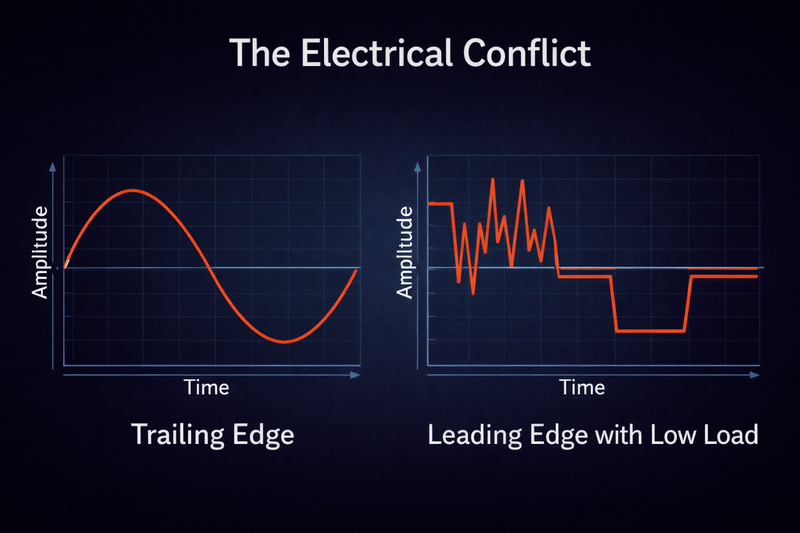

Will Old Track Dimmers Cause the Filaments to Flicker?

Track lighting systems in commercial spaces often run on high-capacity dimmers designed for 50-watt halogen bulbs. When you replace them with 4-watt LED filaments, the electrical load is too low for the dimmer to register, leading to strobing.

Most legacy track lighting dimmers are "Leading Edge" (TRIAC) models requiring a minimum load of 40-60 watts to function stably. Since a track full of LED Edison bulbs might only draw 20 watts total, you must upgrade to "Trailing Edge" (ELV) dimmers or use specific "High-Compatibility" LED drivers.

This is the most frustrating phone call I get.

"Wallson, your bulbs are flashing like a disco."

It is rarely the bulb's fault. It is the mismatch between 1990s infrastructure and 2020s technology.

The Minimum Load Issue

Old magnetic dimmers work by chopping the electricity wave.

To do this, they need resistance. They expect heavy halogen bulbs.

Imagine a strong man pushing a heavy door. He leans effectively.

Now imagine him pushing a feather. He falls over.

Low-wattage LEDs3 are the feather.

A typical track might have 4 heads.

If you use 50W Halogens = 200 Watts. The dimmer is happy.

If you use 5W Edisons = 20 Watts.

The dimmer "loses" the signal. It turns on and off rapidly trying to find the load.

This is the flicker.

The H-Track, J-Track, L-Track Confusion

In the USA, track systems come in three shapes: Halo (H), Juno (J), and Lightolier (L).

This describes the copper contacts on the track.

It does not describe the voltage.

Most home tracks are 120V Line Voltage. Our bulbs work there directly.

However, some high-end commercial tracks are 12V Low Voltage using a remote magnetic transformer.

Warning: You generally cannot put a standard E26 Edison bulb on a 12V track unless you have a bulky adapter with a transformer inside each head.

Most Edison bulbs are 120V or 220V.

You must verify the track voltage.

If you screw a 120V bulb into a track that is actually low voltage (via an adapter), it won't light.

If you screw a 12V bulb into a 120V track, it explodes.

The Driver Solution

We can build bulbs with "High PF" (Power Factor) drivers.

These drivers are smarter. They mimic the behavior of a resistive load (like a halogen).

They trick the dimmer into working smoothly.

But they cost money.

Standard driver: $0.20.

Dimming driver: $0.45.

Pro Dimming driver: $0.80.

If Jacky buys the cheapest bulb to win a bid, he will lose on the installation labor when the electrician has to replace the dimmer switch.

I always advise: "Spend the extra $0.40 on the driver. It is cheaper than a certified electrician's hourly rate."

| Dimmer Type | Technology | LED Compatibility | Min Load |

|---|---|---|---|

| Leading Edge (TRIAC)4 | Old / Magnetic | Poor to Average | High (40W+) |

| Trailing Edge (ELV)5 | New / Electronic | Excellent | Low (5W) |

| Smart Dimmer (Wifi) | Digital | Variable (Check neutral) | Very Low |

Can You Hang Pendants from a Track for a Better Look?

Sometimes the track is on a high ceiling (12 feet), and the small Edison bulb looks lost and provides no useful light on the table below. Using pendant adapters allows you to drop the light source closer to the user, creating a custom chandelier effect.

Track Pendant Adapters allow you to suspend heavy electrical cords from a standard track rail, creating flexible dining lighting without moving a junction box. When pairing these with Edison bulbs, you must ensure the adapter has a "strain relief" strong enough to hold heavy oversized glass bulbs like the PS160.

This is the secret weapon of interior designers.

Track lighting usually looks industrial.

Edison bulbs look vintage.

How do you bridge the gap? The Pendant Adapter.

Instead of a stiff metal head that snaps into the track, this is a plastic connector with a wire hanging out.

You can adjust the length of the wire.

The Design Flexibility

Imagine a restaurant.

They want to move the tables around for different parties.

If they have fixed hanging lamps, they can't move the tables without the light being in the wrong spot.

With track pendants6, they can slide the lights along the rail to match the table position.

They can group three Edison bulbs together to make a "cluster" or spread them out.

This is functionally brilliant.

The Weight Problem

We discussed Giant Bulbs (PS160, BT180) in another article.

They are heavy.

A standard track adapter is plastic.

It relies on a small plastic tab to lock into the copper rail.

If you hang a 500g glass bulb + a 500g brass socket + a heavy decorative cord... you have a 1kg weight potential.

Over time, the plastic track adapter can crack from the stress.

Or worse, the heavy cord pulls out of the adapter.

The Fix:

- Strain Relief: The adapter must have a screw-clamping mechanism that bites into the wire jacket, not just the copper conductors.

- Mechanical Lock: For heavy bulbs7, use adapters that have a mechanical latch, not just a friction fit.

- Counterweights: Sometimes we see cords that are curled/coiled. The weight of the bulb pulls them straight. This looks messy. You need a fabric-braided cable8 that is stiff enough to hang straight but strong enough to hold the weight.

The Socket Choice

When hanging a pendant from a track, the socket becomes very visible.

Don't use cheap white plastic sockets.

Use Solid Brass9, Aluminum, or Bakelite.

The Edison bulb is "jewelry." The socket is the "setting."

If the setting looks cheap, the diamond (bulb) looks fake.

Top-tier designers mix materials: Matte Black Track + Antique Brass Adapter + Amber Glass Bulb.

This contrast sells.

| Component | Standard Option | Designer Upgrade | Why Upgrade? |

|---|---|---|---|

| Adapter Body | White Plastic | Polycarbonate/Metal | Durability & Heat |

| Cord Type | PVC Round | Fabric Braided Twisted | Vintage Aesthetic |

| Socket Material | Bakelite | Solid Brass9 | Premium Feel |

| Strain Relief | Plastic clip | Metal Set Screw | Holds Heavy Glass |

Conclusion

Track systems and Edison bulbs are a difficult marriage of "New Tech" and "Old Look." To make it work, you must avoid canister fixtures that trap heat, upgrade old dimmer switches to prevent flickering, and embrace the omnidirectional nature of the light by using open-socket designs or pendant adapters.

Discover how Half-Chrome bulbs can enhance your lighting experience by minimizing glare while maintaining style. ↩

Explore the advantages of Edison bulbs for aesthetic and functional lighting solutions. ↩

Understanding the challenges of low-wattage LEDs can help you make informed lighting choices. ↩

Explore the benefits and limitations of TRIAC dimming technology for better lighting control. ↩

Discover how Trailing Edge dimming can improve LED compatibility and performance. ↩

Explore how track pendants enhance design flexibility in lighting, allowing for easy adjustments. ↩

Learn about the issues heavy bulbs can cause and how to address them for safe installations. ↩

Find out why fabric-braided cables are preferred for their strength and vintage look in lighting designs. ↩

Discover the benefits of using Solid Brass for light sockets, enhancing both durability and aesthetics. ↩ ↩