You sell standard straight-filament bulbs and they do the job. But your high-end customers want something that looks like a sculpture, not just a tool. You need a product that justifies a higher price point through pure visual appeal.

Spiral Filament LED bulbs—often referenced as "Soft Filament" or "Flexible LED"—use a pliable polymer substrate that allows the light source to curve and twist. This design mimics the intricate hand-wound carbon filaments of the 1900s, offering a glare-free, organic glow that turns any exposed socket into a luxury fixture.

Lighting is no longer just about seeing in the dark. It is about how the light requires you to feel.

I remember when the first LED filament bulbs appeared in 2012. They were stiff. They had straight, yellow sticks inside. They looked like ladders.

Technically, they were perfect. Aesthetically, they were boring.

Then, around 2016, the "Soft Filament" technology matured.

I showed the first sample to my American client, Jacky. He held it up to the light. He smiled.

"Wallson," he said, "Now this looks like a real antique."

The Spiral Filament is the bridge between the efficiency of the future and the romance of the past.

It removes the harshness of LED.

Instead of a sharp point of light, you get a flowing river of light.

For a B2B buyer, this is your high-margin category. You do not sell these by the thousand for a warehouse project. You sell them to boutique hotels, coffee shops, and designers who care about the vibe.

Why Does the Curved Shape of a Spiral Filament Eliminate the "Laser Eye" Effect?

Standard LED bulbs with straight sticks create intense hot spots that dazzle the eye. When a customer sits at a dinner table, they do not want to be blinded by a naked bulb. You need a design that spreads the luminance.

The spiral design spreads the total lumen output across a much longer physical length compared to straight sticks. This increased surface area lowers the "surface brightness" substantially, creating a gentle, continuous line of light that is comfortable to look at directly, even without a lampshade.

We call it the "Squint Test."

Stand two meters away from a bulb. Look right at it.

If you have to squint because it hurts, it is a bad bulb for a dining room.

The Spiral LED passes the Squint Test every time.

The Physics of Surface Brightness

To understand why spirals sell, you have to understand "Glare." Glare happens when a lot of light comes from a very small point.

Think of a laser pointer. It is low power, but the point is tiny, so it hurts.

A standard "straight stick" LED filament is very concentrated.

A spiral filament is different. We take the same amount of light (let's say 300 Lumens) and we spread it out over a curled strip that is maybe 30 centimeters long if you unrolled it.

Because the light is spread out, the intensity per square millimeter is lower.

This creates a "Soft" light.

I have many cafe owners who specifically ask for my spiral T30 bulbs (the long tubes) because straight ones were giving their customers headaches.

The spiral allows the bulb to be the lamp. You do not need a shade. The filament itself is the decoration.

The Organic Aesthetic

Humans love curves. In design psychology, straight lines represent order and logic, but curves represent nature and comfort.

The straight filament bulb looks like a machine.

The spiral filament bulb looks like a living thing.

When we wind the filament into a "Double Helix" (like DNA) or a loose spring, it catches the eye.

My client Jacky sells a lot of "Steampunk" and "Industrial" fixtures.

These fixtures are made of black iron pipes and cages. They are very masculine, very hard.

When you put a Spiral bulb inside, the curves soften the whole look. It creates balance.

The reflection on the glass is also better. A curved light source creates curved reflections on the inside of the glass bulb, adding depth and sparkle that you do not get with straight sticks.

The Warmth Factor (Kelvin)

Spiral filament1s are almost always paired with very warm color temperatures.

We usually produce these in 2200K (Candlelight) or even 2000K (Sunset).

We also coat the glass in gold or amber.

Why? Because the spiral is mimicking flame or hot carbon.

If we made a spiral bulb in 4000K (Cool White), it would look like a weird neon sign. It would feel unnatural.

The combination of the curved shape and the warm color triggers a primal relax response in the brain. It feels like a campfire.

This is why high-end restaurants buy them. They want customers to relax, stay longer, and order more wine.

| Feature | Straight Filament Bulb | Spiral Filament Bulb | Customer Experience |

|---|---|---|---|

| Light Source | Concentrated Points | Continuous Line | Spiral is gentler on eyes. |

| Glare Level | High | Low | Spiral effectively prevents eye strain. |

| Visual Style | Functional / Rigid | Artistic / Fluid | Spiral acts as decor. |

| Typical CCT | 2700K - 6500K | 1800K - 2200K | Spiral creates warmer mood. |

How Do We Bend LED Chips Without Breaking the Circuit?

Standard LED filaments are made on ceramic or sapphire, which snaps if you try to bend it. To create a spiral, we had to reinvent the core material of the filament itself.

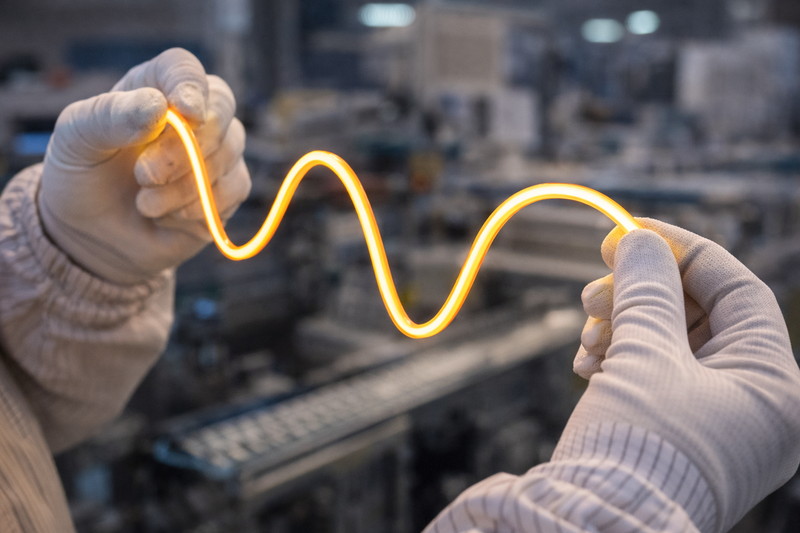

Spiral filaments use a specialized flexible polymer substrate (FPC) rather than rigid ceramic. This transparency-enhanced plastic mimics the pliability of a rubber band, allowing us to mount microscopic LED chips onto it and then shape the entire strip effectively before sealing it inside the glass bulb.

I spend days in our engineering lab watching how these are made. It is not easy.

Making a straight stick is like building a road. Making a spiral is like building a rollercoaster.

The Polymer Substrate Revolution

The old way was rigid. You take a piece of ceramic, put glue on it, and stick the LEDs down.

The new way uses a clear, high-temp plastic material.

It looks like a thin strip of jelly.

This material has to do three things:

- Bend: It must coil tightly without cracking.

- Conduct: It must have microscopic gold pathways to carry electricity.

- Survive: It must withstand the heat of the LEDs without melting.

This is where quality varies.

Cheap polymer turns yellow and brittle after 500 hours.

High-quality polymer (which we use at Hongyu) stays clear and flexible.

If you buy cheap spiral bulbs, you might see the filament sag or droop after a few months because the polymer softened too much in the heat.

The "Phosphor Silicone2" Coating

Once the tiny LED chips are on the plastic strip, we cover the whole thing in yellow goo.

This is a mix of Silicone and Phosphor powder.

- Silicone: Protects the chips and holds everything together.

- Phosphor: Turns the blue light of the LED chip into warm yellow light.

The spiral filament requires a thicker coating than straight sticks.

Why? Because when you bend it, you stretch the outer edge. If the coating is too thin, it cracks, and blue light leaks out.

We call this "Blue Leak3." It looks terrible.

Next time you assess a sample, look closely at the bends. If you see tiny blue cracks, reject it. Ideally, the yellow color should be consistent all the way around the curve.

The Shaping Process

This is the fun part.

The filament starts flat and straight.

We have a machine that looks like a motorized curling iron.

Workers (or robots) wind the filament around a metal rod to set the shape.

For complex shapes, like a "Love" word or a flower, we use a mold.

The filament has "Memory4."

We have to heat it slightly to shape it, then cool it down so it stays that way.

Then, we spot-weld it to the metal stem inside the bulb.

This welding needs to be strong. Since the filament is a spring, it bounces during shipping. If the weld is weak, the filament falls off.

I continuously drop-test our spiral bulbs to make sure the springy filament doesn't shake itself loose.

| Component | Standard Filament | Spiral (Soft) Filament | Engineering Challenge |

|---|---|---|---|

| Base Material | Sapphire / Ceramic | Flexible Polymer5 | Must withstand heat without melting. |

| Stiffness | Rigid / Brittle | Pliable / Elastic | Preventing sagging over time. |

| Coating | Thin Phosphor | Thick Phosphor/Silicone | Preventing cracking at bends. |

| Assembly | Pick & Place | Winding & Shaping | Maintaining uniform shape. |

Which Spiral Pattern Fits Best in High-End Decorative Fixtures?

Not all spirals are the same. A tight spring creates a different visual effect than a loose wave. You need to match the filament geometry to the bulb size and the interior design style.

The most popular patterns are the Single Helix (for small bulbs like G45), the Double Helix (for standard A60/ST64), and the Tree/Vertical Spiral (for large globes like G125). Large globes require complex, vertically stretching filaments to fill the glass volume, while smaller bulbs need tighter coils to maximize brightness in a small space.

Design is about proportion.

A tiny spiral in a huge bulb looks lonely.

A huge spiral in a tiny bulb looks crowded.

You have to find the right fit.

The Double Helix[^6] (The DNA Look)

This is the bestseller for ST64 (Teardrop) and A60 (Standard) bulbs.

It consists of two intertwined spirals.

It looks very scientific yet vintage.

When you put this in a wall sconce, it looks amazing from every angle.

It is symmetric.

If you look at it from the side, the lines cross each other creates a beautiful "X" pattern of light.

This is the safest bet for retail. It fits almost any lamp.

The "Tree" or "Vertical" Spiral

For big bulbs like the G125 (Globe) or T30 (Long Tube), a small coil is not enough.

We need the filament to stretch from the top to the bottom.

We use a "center pillar" made of glass.

We wind the filament around this pillar, up and down.

It looks like a glowing tree inside the glass.

This is critical for long pendant lights.

If you have a long straight cage, you need a long vertical spiral (T30) to fill it.

If you use a short spiral, the bottom of the cage looks empty and dark.

The "Random" or "Messy" Loop

Sometimes, perfection is boring.

Some designers want a "Chaos" look.

We just stuff a long flexible filament inside the bulb and let it curve randomly.

It looks like a glowing noodle.

This is very artistic, but hard to mass-produce with consistency.

One bulb might look great, the next one looks weird.

I usually advise Jacky to avoid "Random" patterns for big retail orders because customers complain if the two bulbs they bought don't match.

Stick to the Helix. It is repeatable and tidy.

Custom Shapes[^7]: Words and Icons

Because the filament is flexible, we can shape it into letters.

"LOVE", "HOME", "BAR", or a Heart shape.

These are novelty items.

They sell well directly to consumers as gifts.

But for a serious lighting project (like a hotel), they are too gimmicky.

However, stocking a few "Heart" filament bulbs for Valentine's Day is a smart quick-cash move for a retailer.

| Bulb Shape | Best Spiral Pattern | Why? | Target Style |

|---|---|---|---|

| ST64 (Teardrop) | Double Helix | Fills the teardrop shape perfectly. | Vintage Industrial |

| G80 / G95 (Globe) | Single Up-Down Loop | Simplistic, floats in middle. | Modern Minimalist |

| G125 (Large Globe) | Vertical Tree Spiral[^8] | Fills the massive volume. | Luxury Statement |

| T30 (Long Tube) | Long Cylinder Spiral | Matches length of tube. | Linear Pendants |

What Are the Hidden Risks of Flexible Filaments That Suppliers Don't Tell You?

Flexible filaments trap heat more than rigid ones. If the factory overdrives them to get more brightness, the polymer degrades and the light fails. You must prioritize lifespan over maximum lumens.

Spiral filament bulbs are heat-sensitive and should never be driven at high currents; they are designed for decorative accent lighting (low lumen), not primary task lighting. To ensure longevity, you must insist on Helium gas filling for thermal management and high-quality IC drivers that keep the electrical current stable.

Here is the truth that hurts: Spiral bulbs often have a shorter lifespan than straight ones if not made correctly.

Why? Because plastic (polymer) acts as an insulator.

Sapphire (stone) conducts heat away. Plastic keeps heat in.

If the heat stays in the LED chip, the chip dies.

The Wattage Limit

Do not ask me for a "100W Equivalent" spiral bulb. It does not exist.

If a factory promises you a 10 Watt spiral bulb (1000 lumens), they are lying, or the bulb will burn out in a month.

The safe limit for spiral filaments is about 4 to 5 Watts.

This gives you about 250 to 350 lumens.

This is "Accent Light." It is for mood. It is not for reading a book.

I have to explain this to buyers constantly.

"Jacky, if we push more power, the polymer melts."

We keep the wattage low to keep the temperature low.

The Helium Requirement

I mentioned this before, but for spirals, it is life or death.

Air is a heat insulator.

Helium is a heat conductor.

Because the filament substrate (plastic) is bad at moving heat, we must rely on the gas surrounding it.

We pump a mix of Helium and Oxygen into the glass bulb.

The Helium grabs the heat from the spiral and carries it to the glass wall.

The glass wall touches the air in the room, and the heat escapes.

Cheap factories use Nitrogen or just air.

Without Helium, the core of the spiral filament gets to 120°C. The safe limit is 85°C.

When you buy, ask for the "Gas Analysis Report."

The Driver Stability

Because we are running these bulbs at low power (dim), the driver must be precise.

Linear drivers (cheap) cause flicker.

Flicker is more noticeable in spiral bulbs because the filament is so long.

Also, voltage fluctuations can cause the spiral to heat up unexpectedly.

We use Constant Current IC drivers.

They lock the current at a safe level (e.g., 20mA).

Even if the voltage in the house spikes, the driver protects the sensitive polymer filament.

It costs $0.15 more, but it saves your brand reputation.

The "Sag" Test

Before we ship, we do an "Aging Test."

We hang the bulb upside down and light it up for 24 hours.

Why upside down?

Because gravity pulls the spiral down.

If the polymer is bad quality or the design is too heavy, the spiral will stretch and sag like melted cheese.

It looks sad.

A high-quality spiral keeps its bouncy, tight shape even when hot.

When you receive your shipment, take a few bulbs, light them up upside down for a day, and check if the shape changes.

| Risk Factor | Cause | Result | Solution |

|---|---|---|---|

| Overheating | Poor Thermal Conductivity | LED Burnout / Dimming | Helium Gas Fill |

| Melting / Sagging | High Current / Bad Polymer | Deformed Shape | Low Wattage / Quality Polymer |

| Flicker | Linear Driver | Visual Strobe | IC Constant Current Driver |

| Short Life | Overdriving for Lumens | Returns & Complaints | Accept Lower Lumen Output |

Conclusion

Spiral filament bulbs are the ultimate fusion of modern LED technology and vintage aesthetics, offering a glare-free, organic light that standard bulbs cannot match. However, they require careful engineering—specifically quality polymer substrates, helium cooling, and conservative wattage ratings—to ensure the beautiful form does not fail due to heat.

Explore the Double Helix design to understand its unique aesthetic and how it enhances lighting fixtures. ↩

Find out how Custom Shapes are made and their potential for unique, personalized lighting solutions. ↩

Learn about the Vertical Tree Spiral to see how it transforms large bulbs into stunning light sources. ↩

Discover the significance of memory in filament materials for maintaining shape and performance in lighting applications. ↩

Explore how flexible polymer enhances LED performance and longevity, ensuring better quality and durability. ↩