You've sourced a beautiful, high-end light fixture. But the recommended LED filament bulb casts ugly shadows and creates a dark "cave effect" on the ceiling, making your premium product look cheap and leading to customer dissatisfaction.

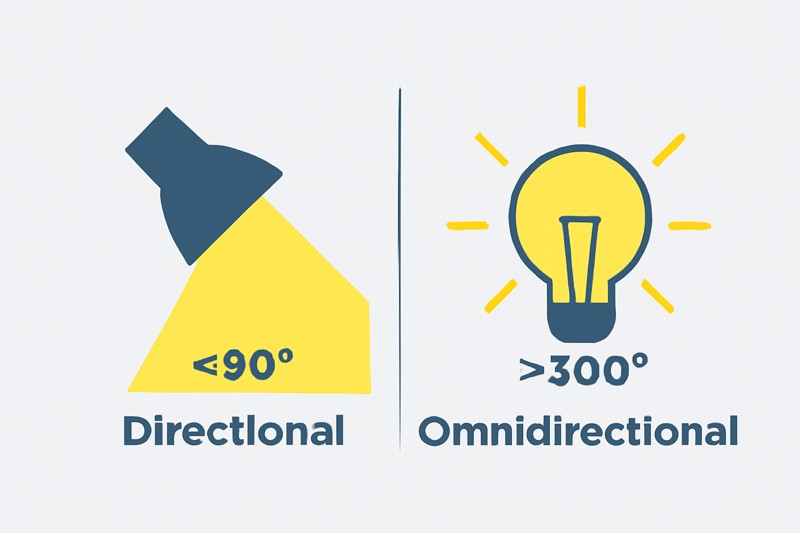

True lighting success requires an omnidirectional beam angle, typically over 300 degrees. This ensures the LED filament bulb radiates light evenly in all directions, just like a traditional incandescent, eliminating shadows and creating a full, room-filling glow.

I remember a difficult situation with a new client from the Netherlands, a very meticulous product manager we'll call Jacky. He had designed a stunning range of minimalist table lamps with semi-translucent fabric shades. To keep his costs down on the initial order, he bundled them with some very cheap LED filament bulbs he found from another supplier. The photos for his catalog looked perfect. But when the lamps reached customers, the complaints flooded in. The bulbs had a large, opaque plastic base where the driver was housed—a common cost-cutting design. This base blocked all downward light, creating a stark, ugly shadow on the bottom half of the lampshade and leaving the table surface in darkness. The lamp, designed to create a pool of warm light, failed completely. He called me in a panic. We rush-shipped him a batch of our Hongyu Bulb A19s, which use a micro-driver in the screw base and have a clear, unobstructed glass shell. The problem vanished instantly. His lamps glowed evenly from top to bottom. It was a costly lesson for him, but it perfectly illustrated that the success of a lighting fixture is completely dependent on the quality of the light distribution from the bulb inside it.

What Exactly is an Omnidirectional Beam Angle?

The spec sheet on an LED bulb is full of numbers, but one of the most critical is often ignored. Why does this single specification, "beam angle," determine whether a bulb creates a beautiful ambiance or a harsh, uneven spotlight?

Omnidirectional light means the bulb emits light evenly in a full, near 360-degree sphere. This is the opposite of a directional bulb (like a spotlight), and it is absolutely essential for recreating the warm, room-filling glow of an incandescent.

The term "beam angle" refers to the angle at which the light intensity drops to 50% of the maximum intensity at the center of the beam. For a spotlight used to highlight a piece of art, a narrow beam angle of 25 degrees is perfect. But for the main bulb in a table lamp, a chandelier, or a ceiling fixture, a narrow beam angle is a disaster. Early generations of LED bulbs were notoriously directional because the flat LED chips were mounted on a circuit board that only faced one way. This created the infamous "cave effect," where a ceiling fixture would light up the floor but leave the ceiling and upper walls in gloomy darkness. The invention of the LED filament was the solution to this problem. By arranging the LED sources on vertical pillars inside a clear glass shell, we can finally mimic the all-around glow of a tungsten filament. A true filament bulb should deliver a beam angle of 300 degrees or more, providing the even, comfortable illumination that customers subconsciously expect from general lighting.

Understanding the Spectrum of Light Distribution

Not all beam angles are created equal. As a buyer, understanding these categories helps you source the right product for the right application and avoid misapplication.

| Beam Angle Type1 | Angle Range | Light Characteristics | Common Applications |

|---|---|---|---|

| Spot (Directional) | < 60 Degrees | A focused, high-intensity beam. Creates sharp shadows. | Track lighting, art highlighting, landscape spotting. |

| Flood (Wide) | 60 - 150 Degrees | A broader cone of light, good for illuminating general areas. | Outdoor security lights, recessed ceiling cans. |

| Omnidirectional2 | > 300 Degrees | Even, room-filling light in all directions. Soft shadows. | Table lamps, pendants, chandeliers, any fixture with a shade. |

Sourcing true omnidirectional LED filament bulbs is the only way to guarantee a direct, one-to-one replacement for incandescent bulbs in general lighting fixtures. Anything less will compromise the performance of the luminaire and lead to end-user disappointment.

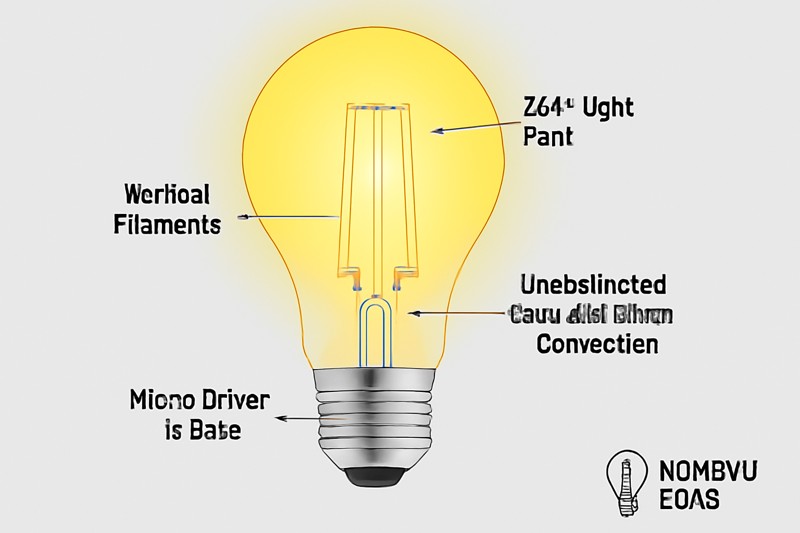

How Does Bulb Design Achieve a 360-Degree Glow?

You see two A19 filament bulbs that look almost identical. One creates a perfect, even sphere of light, while the other has a noticeable dark spot at the base. What invisible design choice is causing this critical performance difference?

A true 360-degree glow is achieved by a trinity of smart design: vertically oriented LED filaments, a miniaturized driver housed entirely within the screw base, and the absence of a large, light-blocking plastic heat sink between the glass and the base.

Achieving a truly seamless, omnidirectional light is a significant engineering challenge that separates premium manufacturers from low-cost assemblers. It’s not enough to simply string LED filaments inside a bulb. Every component must be designed to minimize light obstruction.

First is the filament orientation. By mounting the LED filament strips vertically and arranging them in a cage-like structure, we ensure light is projected outwards in a 360-degree horizontal plane, mimicking the structure of a tungsten filament.

Second, and most critically, is the driver and heat sink. Cheaper bulbs use larger, less efficient drivers that generate more heat. This requires a large, external plastic heat sink that forms a solid collar between the glass bulb and the metal screw base. This collar blocks 60 to 90 degrees of downward light, creating the exact shadow problem my client Jacky experienced. At Hongyu Bulb, we invest in highly efficient, miniaturized driver components. This allows us to build the entire driver inside the metal E26 or E27 screw base. This eliminates the need for an external heat sink, allowing the glass shell to connect directly to the base and ensuring light can travel down and out without obstruction.

The Anatomy of Light Distribution

The quality of a filament bulb's light spread comes down to a few key design choices that you should look for during sourcing.

| Component | Low-Quality Design (Poor Beam Angle) | High-Quality Design (Omnidirectional) |

|---|---|---|

| LED Filaments | Clustered or only facing one direction. | Arranged vertically in a 360° cage3. |

| Driver | Large, inefficient components requiring heat sinking. | Miniaturized, efficient, and housed in the base. |

| Heat Sink / Base | A large, opaque plastic collar blocks downward light. | No external heat sink; glass connects to the metal base. |

| Result | A beam angle4 of 200-240°, with a significant "dark spot." | A true >300° beam angle with even illumination. |

When you are evaluating samples, don't just look at the bulb when it's off. Screw it into a simple socket and hold it up. If you see a prominent dark area near the base, you know it will perform poorly in a huge number of common lighting fixtures.

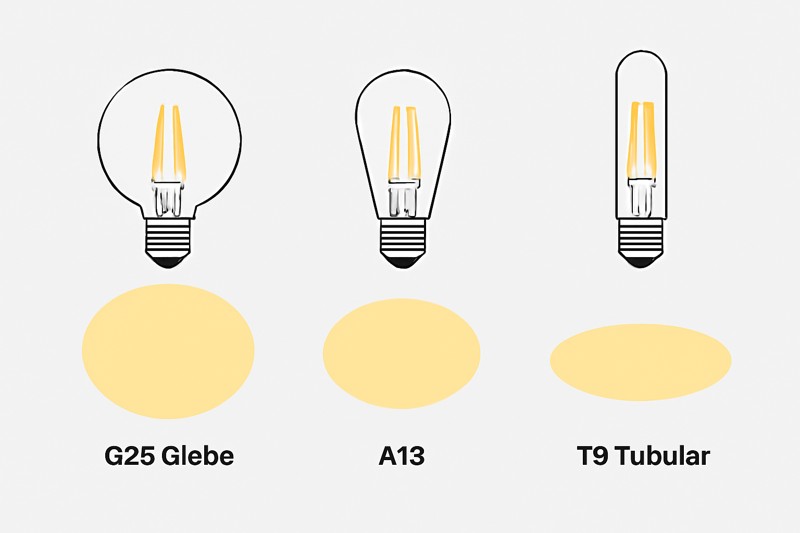

Does Bulb Shape Change the Light Distribution?

Your customer loves the aesthetic of a long, tubular T9 bulb for their dining room chandelier. But after installation, they notice the round table below is unevenly lit. Is this a defect, or is the bulb's shape itself the cause?

Yes, the bulb's physical shape is a critical factor in the final light distribution pattern, even if the source is omnidirectional. Different shapes are like different types of speakers; they create different patterns of sound, or in this case, light.

This is an area where a deeper level of product knowledge can help guide your customers to the perfect solution. While our omnidirectional design ensures light leaves the bulb in all directions, the geometry of the glass then shapes that light. Think of it like water coming from a hose: the source is the same, but different nozzles will create different spray patterns. The same is true for bulbs. A spherical bulb, like our G25 or G40 Globe series, is the purest form. It creates a beautiful, even, and symmetrical sphere of light, making it the absolute best choice for bare-bulb pendants, sputnik chandeliers, or any fixture where an even glow is paramount. A standard A19 "A-series" bulb is designed to be a generalist. Its shape provides a very wide and useful distribution that works well in almost any application, from table lamps to ceiling fixtures. A tubular "T-series" bulb, on the other hand, is a specialist. Because the light source is a long line of filaments within a long tube, it naturally casts a more oblong or linear pattern of light. This makes it a fantastic choice for lighting a long rectangular dining table, a kitchen island, or for use in a multi-pendant installation where you want to create linear patterns.

Matching Bulb Shape to the Application

Guiding your customers to the right shape for their fixture is a value-added service that prevents dissatisfaction.

| Bulb Shape Series | Description | Light Distribution Pattern5 | Ideal Fixture Types6 |

|---|---|---|---|

| A-Series (A19) | The classic, standard bulb shape. | Wide, general, all-purpose distribution. A great default. | Table lamps, floor lamps, enclosed ceiling fixtures. |

| G-Series (G25, G40 Globe) | A perfect sphere of glass. | The most even, symmetrical, spherical pattern. | Bare-bulb pendants, sputnik chandeliers, bathroom vanities. |

| T-Series (T9, T10 Tubular) | A long, narrow tube shape. | Oblong, linear pattern. Excellent for long surfaces. | Pendants over kitchen islands, linear chandeliers, sconces. |

| ST-Series (ST19, ST64) | The classic "Edison" teardrop shape. | A mix between A-series and G-series, slightly elongated. | Exposed pendants, industrial-style fixtures, string lights. |

By understanding how shape influences the final pattern of light, you can move beyond simply selling "a bulb" and start providing sophisticated lighting solutions. This expertise builds trust and sets your brand apart.

Conclusion

For true incandescent replacement, demand omnidirectional bulbs with a beam angle over 300 degrees. Scrutinize the design for vertical filaments and no light-blocking heat sink. Match the bulb shape to the fixture for perfect light distribution.

Understanding beam angle types can significantly improve your lighting design and application effectiveness. ↩

Explore the advantages of omnidirectional LED bulbs to enhance your lighting choices and ensure optimal performance. ↩

Understanding the 360° cage design can help you choose bulbs that provide even light distribution, enhancing your lighting experience. ↩

Exploring beam angle effects will guide you in selecting bulbs that meet your specific lighting needs, ensuring optimal illumination. ↩

Understanding light distribution patterns helps in choosing the right bulb for specific fixtures, enhancing overall lighting quality. ↩

Exploring ideal fixture types ensures that customers select the best bulbs for their needs, improving satisfaction and performance. ↩