You buy ten vintage light bulbs for your new chandelier. You screw them in. You switch them on. Disaster strikes. Five bulbs glow like a sunset, three look like a hospital hallway, and two are somewhere in between.

To guarantee color consistency in LED Edison bulb manufacturing, we use a strict process called "Binning." We measure every single LED filament chip using MacAdam Ellipse standards (SDCM), sorting them into narrow groups so that the human eye cannot detect any color difference between two bulbs from the same batch.

I have a customer named Jacky.

Jacky buys thousands of bulbs from me every year.

Last year, he called me in a panic.

"Wallson," he said. "My client is furious. He installed 50 bulbs in a restaurant. The left side of the room looks pink. The right side looks green. They are all supposed to be 2700K!"

I asked him where he bought them.

He admitted he bought a "cheap lot" from a different factory to save money.

This is the nightmare of Color Consistency.

It is the invisible quality.

When you hold a light bulb in your hand, you cannot see it.

You only see it when you turn it on.

In the old days of Tungsten bulbs, physics was simple.

You heated a wire. It glowed.

If the wire was the same length, the color was the same.

But LED is different.

LED is a semiconductor.

It is grown in a lab, like a crystal.

When you grow crystals, no two are identical.

One batch comes out slightly blue. One batch comes out slightly yellow.

If I just took these chips and put them into bulbs, my customers would leave me.

So, we have to filter them.

We have to sort them.

We have to be obsessed with the "Coordinates" of color.

What Is the "MacAdam Ellipse" and Why Does It Matter?

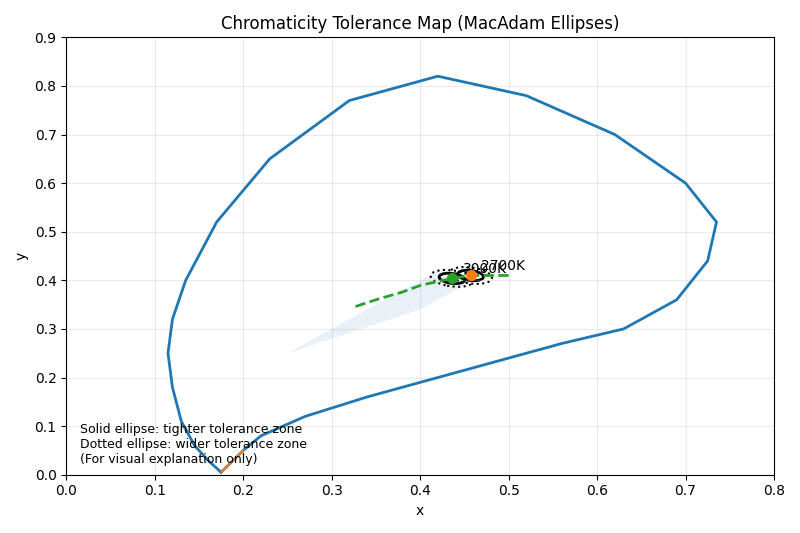

You might think "Warm White" is a single color. It is not. It is a range. To define exactly which warm white we are selling, we need a scientific map of human vision.

The MacAdam Ellipse is a region on the chromaticity diagram (a color map) that defines how much color variation the human eye can see. If all your LED chips fall within a "3-Step" MacAdam Ellipse, the difference is invisible to the naked eye. If they fall outside, the customer sees mismatched colors.

Imagine a target board for archery.

The Bullseye is the perfect color. Let's say 2700 Kelvin.

In the factory, we shoot arrows (make chips) at the target.

We cannot hit the exact center of the bullseye every single time.

Physics prevents it.

But we can hit near the center.

Step 1 Ellipse:

This is the tiny circle right in the center.

If all your shots land here, the color is perfect.

Laboratory equipment cannot even tell the difference.

But these chips are very rare and very expensive.

Step 3 Ellipse (SDCM < 3):

This is a slightly bigger circle.

To the human eye, everything inside this circle looks identical.

This is the industry standard for high-end hotels and museums.

My factory aims for this level.

Step 5 Ellipse (SDCM < 5):

This is a bigger circle still.

If you put a Step 5 bulb next to a perfect bulb, you might see a difference.

One might look a bit "crisper."

This is acceptable for cheap residential lighting.

Step 7 Ellipse:

This is a huge circle.

This is what Jacky bought from the cheap factory.

Some bulbs are yellow. Some are pink. Some are purple.

They are all technically "2700K," but they look terrible together.

The Trade-Off

Why doesn't everyone sell Step 31?

Cost.

To get Step 3 consistency, I have to throw away (or sell cheaply) the chips that land in the outer circles.

It is like buying strawberries.

If you only sell the perfect, red, same-sized strawberries, you have to charge more.

If you sell the whole basket, green ones and bruised ones included, you can be cheap.

I tell my B2B clients2: Do not pay for Step 7 if you want to keep your reputation.

| SDCM Level | Variation | Application | Cost |

|---|---|---|---|

| 1-Step | Invisible | Lab Calibration | Very High |

| 3-Step | Invisible to Eye | High-End Hospitality | High |

| 5-Step | Slightly Visible | General Home Use | Medium |

| 7-Step | Obvious | Street Lights / Cheap Retail | Low |

We know the standard. Now, how do we physically do the sorting? This is where the machines come in.

How Does the "Binning" Process Work in the Factory?

We cannot change the color of an LED chip after it is made. We can only categorize it. This process of testing and bucket-sorting is the heart of quality control.

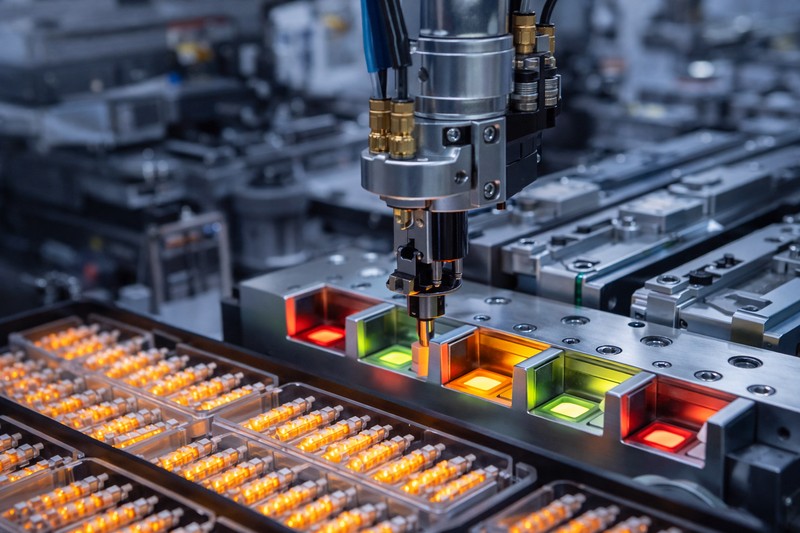

Binning is the automated process where a machine turns on every single LED chip for a fraction of a second, measures its exact light output and color temperature, and then drops it into a specific "Bin" or bucket. We only use chips from the same bin to make a single batch of bulbs.

This happens before the filament is even inside the glass bulb.

We buy millions of LED filaments.

They look orange when they are off.

We feed them into a machine.

ZAP. It flashes.

A spectrometer reads the light.

It says: "This one is exactly 2710K with a pink tint." -> Bin A.

ZAP. Next one.

"This one is 2690K with a green tint." -> Bin B.

"This one is 2700K dead center." -> Bin C.

Managing the Bins:

Now comes the strategy.

I cannot mix Bin A and Bin B in the same order.

If Jacky orders 5,000 bulbs, I must ensure all 5,000 bulbs come from Bin C.

Or, if I run out of Bin C, I can use Bin A.

But I must use only Bin A.

If the whole room is slightly pink, nobody notices.

Our eyes adjust.

The problem happens when you put a Pink bulb next to a Green bulb.

This is called "Delta UV" (Duv).

It measures the distance from the "Black Body Locus" (the pure white line).

We try to keep the Duv close to zero.

Labeling the Batches:

On every box of bulbs we ship, there is a "Date Code" or "Batch Number."

I teach my distributors:

"If you are doing a big project, like a hotel lobby, do not mix Batch 01 with Batch 05."

Even with good binning, there might be tiny shifts between production runs months apart.

Always install from the same batch for critical areas.

The Phosphor Factor

The LED chip is actually blue.

We cover it with yellow "Phosphor" glue.

The blue light hits the yellow phosphor and turns white.

Mixing the phosphor is like baking a cake.

If the worker puts 1 gram too much phosphor powder in the mix?

The light becomes too yellow.

If the layer of glue is 0.1mm too thin?

Blue light leaks through. The bulb looks cold.

We use computers to mix the phosphor paste.

It is precise down to the milligram.

This ensures the coating on the filament is uniform every time.

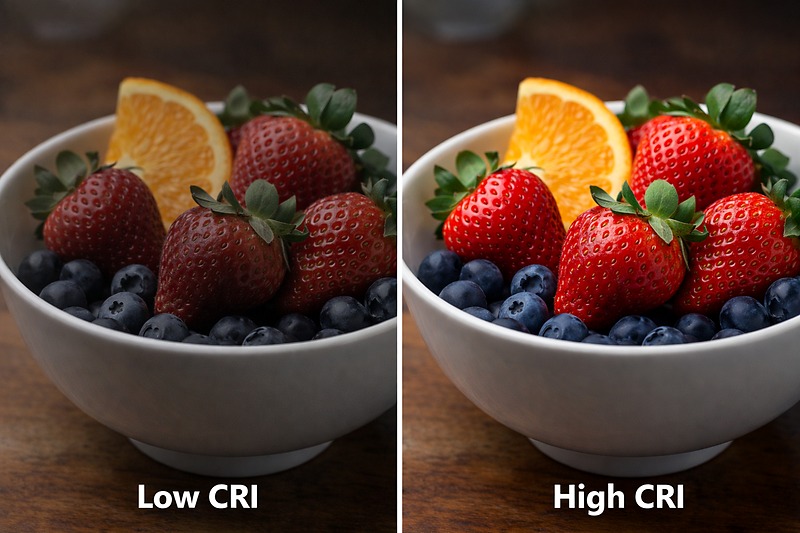

Why Is Color Rendering Index (CRI) different from Color Temperature (CCT)?

You can have two bulbs that are both perfectly 2700K, but one makes an apple look red, and the other makes it look brown. This is not about the color of the light itself, but how the light reveals colors in objects.

Color Consistency refers to the light looking the same (CCT). Color Rendering (CRI) refers to the quality of that light spectrum. High CRI (90+) ensures that reds, blues, and skin tones look natural and vibrant, while low CRI (80-) creates a dull, washed-out effect.

Customers often confuse these two things.

Jacky will say, "I want good color."

I have to ask: "Do you mean you want the bulbs to match each other? Or do you want the furniture to look good under the light?"

Usually, the answer is "Both."

The R9 Value:

Standard CRI is calculated using 8 pastel colors.

It does not include Red (R9).

You can have a "High CRI" bulb with a terrible R9 score.

In this case, skin looks pale. Meat looks old. Wood looks dead.

For LED Edison bulbs, we focus heavily on R9.

Why?

Because these bulbs go in restaurants and homes.

You want your steak to look delicious. You want your date to look healthy.

We add extra red phosphor to our mix to boost the R9 value.

The Consistency of CRI:

Just like CCT, CRI can vary.

One batch might be CRI 92. The next might be CRI 88.

We have to bin for this too.

If you have a row of paintings in an art gallery, and one bulb has low CRI, that painting will look flat.

It ruins the experience.

We guarantee a minimum CRI (usually 90+) for our filament series.

The "Filament" Challenge

It is harder to control color in a filament bulb than a regular plastic bulb.

In a plastic bulb, the LEDs are hidden deep inside. The plastic cover diffuses (mixes) the light.

If the chips are slightly different, the cover blends them.

In an Edison Filament Bulb3, the LED is exposed.

You are looking directly at the source.

There is no cover to hide mistakes.

The phosphor coating on the stick must be perfect.

If the coating is uneven—thick on one side, thin on the other—you get "Angular Color Shift4."

This means the bulb looks yellow from the front, but blue from the side.

We inspect every filament stick under a microscope to ensure the coating thickness is uniform.

Conclusion

Color consistency is the difference between a professional lighting setup and a messy one. By strictly using MacAdam Ellipse binning (Step 3), managing our phosphor mixes with computer precision, and educating clients about batch codes, we ensure that every LED Edison bulb from Hongyu Bulb matches perfectly. We do the hard work in the factory so you don't face surprises on the ceiling.

Understanding Step 3 can help you maintain high standards in your offerings, ensuring customer satisfaction and loyalty. ↩

Exploring B2B client relationship strategies can enhance your business interactions and improve your overall success. ↩

Explore the benefits of Edison Filament Bulbs, including their unique design and lighting effects, to enhance your understanding of modern lighting. ↩

Learn about Angular Color Shift and its impact on lighting quality, helping you make informed choices for your lighting needs. ↩