You’ve just received a massive container of beautiful LED filament bulbs for a major client, but the installation has ground to a halt. The bulbs don't fit the fixtures, and now you're facing angry calls, project delays, and the nightmare of a useless shipment.

This costly error is almost always due to a mismatch between the bulb's base type (e.g., E26, E27, B22) and the regional socket standard of the destination country. To prevent this, you must explicitly confirm the exact socket type and voltage for every international order before production begins.

I'll never forget the sinking feeling I got from a call with Jacky, one of my most reliable clients in the United States. He'd landed a huge contract to supply decorative lighting for a hotel chain opening a new flagship location in London. He placed a massive order for our ST64 filament bulbs, his usual specification. The bulbs were produced, shipped, and arrived on-site. Then the frantic call came. "Wallson, none of them fit! The electricians are laughing at me. It's a catastrophe." He had ordered his standard US product: bulbs with an E26 screw base. The UK standard for that type of fixture is the B22 bayonet mount. He had 10,000 beautiful, high-quality bulbs that were completely useless for his project. The cost of air-freighting a new, correct batch was astronomical, and the project delays nearly cost him the entire contract. That day, I made it our company policy to never start production on an export order without triple-confirming the destination country's socket standard in writing. It was an expensive lesson for Jacky, and a powerful reminder for me that the smallest details can have the biggest financial impact.

Are You Sure Your E26 Bulbs Are Safe for E27 Sockets?

A European client is using your North American-spec E26 bulbs in their E27 sockets. The bulbs seem to fit and light up, but they are reporting intermittent flickering and a surprisingly high failure rate, damaging your reputation for reliability.

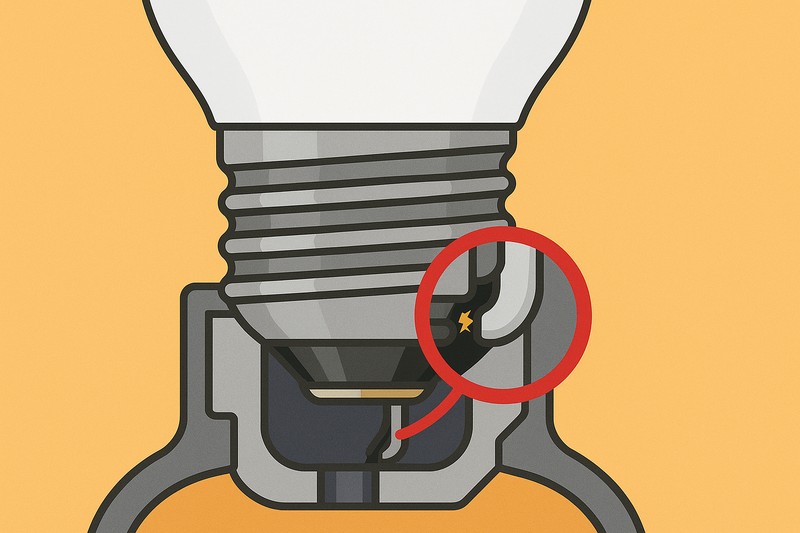

While mechanically similar, an E26 base in an E27 socket can create a poor electrical connection. This leads to micro-arcing that overheats the socket contacts, stresses the bulb's driver, and dramatically shortens its operational life, posing a potential safety risk.

This is the most common and most misunderstood compatibility issue in the world. The E26 base (the standard in 120V North America) and the E27 base (the standard for 220-240V regions like Europe and Australia) are only one millimeter different in diameter. They look identical to the naked eye, and an E26 bulb will physically screw into an E27 socket. This creates a false sense of compatibility. The real problem lies in the length of the screw threads and the height of the insulator at the base. The European E27 standard specifies a greater screw length and a taller insulator for safety at higher voltages. When you put a shorter E26 bulb into a deeper E27 socket, the central "hot" contact at the bottom may not press firmly against the contact tab in the socket. This creates a tiny air gap. Electricity will try to jump this gap, creating a small spark or "arc." This micro-arcing generates intense, localized heat, which can damage both the bulb's contact point and the socket itself over time. This electrical instability also sends a "dirty" power signal to the sensitive driver in the LED bulb, causing it to work harder, overheat, and ultimately fail much faster than its rated life.

The Critical Difference: E26 vs. E27

| Specification | E26 Edison Screw | E27 Edison Screw | Key Implication for Buyers |

|---|---|---|---|

| Diameter | 26 mm | 27 mm | Mechanically interchangeable, but not electrically ideal. |

| Typical Voltage1 | 120V AC | 220V - 240V AC | This is the critical distinction. The bulb's internal driver must match the voltage. |

| Primary Region | North America, Japan | Europe, UK, Australia, Most of Asia | The most important piece of information to confirm before ordering. |

| Safety Standard2 | UL / CSA | CE / IEC | Designed with different electrical safety parameters in mind, especially insulation. |

For the safety and longevity of your products and the satisfaction of your customers, you must always supply the correct, region-specific base. Using an E26 in an E27 socket is a hidden failure point waiting to happen.

Why Won't Your New Bulb Physically Fit in the Old Fixture?

The bulb you supplied has the correct screw base, but the client is complaining that it's useless. The glass part of the bulb is too wide or too long to fit inside the fixture's shade, cage, or glass enclosure.

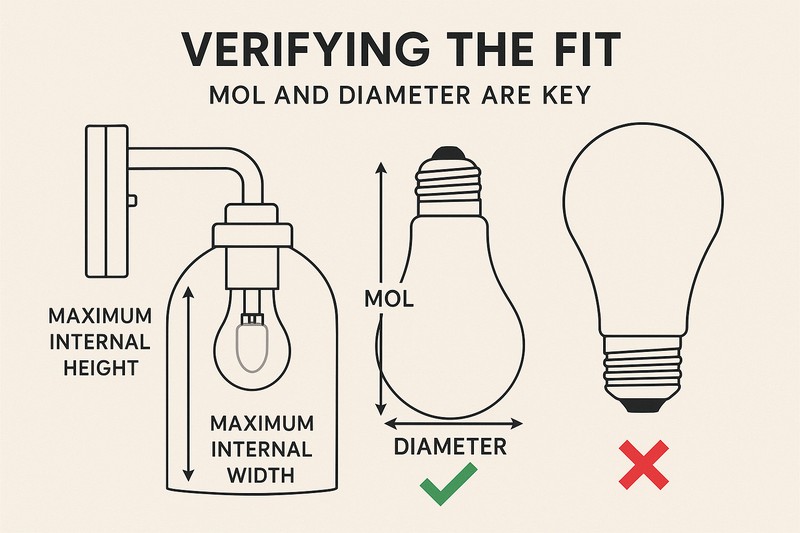

Socket compatibility is only the first step. You must also consider the bulb's physical dimensions: its Maximum Overall Length (MOL) and its maximum diameter. These measurements must be smaller than the internal space of the light fixture.

This is an incredibly common and frustrating problem, especially with decorative fixtures. A buyer might see that a sconce requires an "E26 base bulb" and assume any E26 bulb will work. They then order a beautiful, vintage-style ST64 "Edison" bulb, only to find its long, teardrop shape is too tall to allow the glass cover to be put back on the sconce. Or they order a wide G95 globe bulb for a fixture with a narrow wire cage and find the bulb is too fat to fit through the opening. As suppliers, we must be proactive in preventing this. The specifications for every bulb we produce at Hongyu Bulb include not just the base type and wattage, but the precise MOL and diameter in millimeters. When a client like Jacky is specifying bulbs for a large project with thousands of fixtures, we always advise him to get the internal measurements of the fixture first. If possible, we recommend he test a physical sample of our bulb in their sample fixture before committing to the full production run. This simple "sample fit test" can save tens of thousands of dollars and prevent massive logistical headaches.

Key Bulb Dimensions to Verify

- Maximum Overall Length (MOL)3: This is the total length of the bulb from the very top of the glass to the bottom of the electrical contact on the base. This is the crucial measurement for enclosed fixtures like sconces, ceiling lights with covers, or recessed cans.

- Maximum Diameter4: This is the measurement of the bulb at its widest point. For a G-series (globe) bulb, this is its diameter. For an ST-series (teardrop) bulb, it's the width of the widest part of the glass. This is critical for fixtures with cages, narrow shades, or tight openings.

By training your sales team and educating your customers to ask for these two simple measurements, you can eliminate the majority of physical fit issues and position yourself as a thorough, detail-oriented partner.

Is the E12 vs. E14 Candelabra Confusion Harming Your Chandelier Sales?

A high-end interior designer is specifying your bulbs for dozens of expensive chandeliers in a luxury hotel project. They receive the shipment and find none of the bulbs fit, causing project stalls and potentially losing you a valuable, long-term customer.

This is the miniature version of the E26/E27 crisis. The North American E12 "candelabra" base is not compatible with the European E14 "small Edison screw." Forcing an E12 bulb into an E14 socket will create a loose, unreliable connection and vice-versa.

Chandeliers, wall sconces, and other decorative fixtures often use these smaller candelabra-style bulbs. Because these fixtures are often high-end, designer-specified items, a mistake here can be particularly damaging to a supplier's reputation. The 2mm difference between an E12 and E14 base is much more significant than the 1mm difference between E26 and E27. You often cannot even get an E14 bulb to start threading into an E12 socket. Conversely, an E12 bulb will be extremely loose and wobbly in an E14 socket, making intermittent contact at best. This isn't just an inconvenience; it looks unprofessional and is electrically unsound. For a project manager like Jacky, specifying lighting for a global hotel brand means dealing with fixtures sourced from all over the world. A chandelier in a London hotel might be from an Italian designer (using E14 sockets) while the bedside lamps are from an American brand (using E12 sockets). This requires meticulous attention to detail. We always advise our clients to never assume the socket type based on the fixture's appearance. They must check the technical specifications of the fixture or physically inspect the socket to confirm whether it is an E12 or E14 base before placing a large order. Getting this detail right is a mark of a professional and reliable lighting supplier.

Candelabra Base Quick Reference

| Specification | E12 Candelabra5 | E14 Small Edison Screw (SES)6 | Primary Application |

|---|---|---|---|

| Diameter | 12 mm | 14 mm | Decorative fixtures (chandeliers, sconces, night lights). |

| Region | North America, Japan | Europe, UK, Australia | Critical to confirm based on fixture origin and installation site. |

| Interchangeable? | No. Do not attempt to interchange them. | No. The size difference is too great for a reliable fit. | A mismatch will either not fit or will be dangerously loose. |

Conclusion

Mastering socket compatibility by confirming the base type, voltage, and physical dimensions for every order is not just a technical detail. It is a fundamental business practice that prevents costly errors, builds client trust, and protects your bottom line.

Understanding voltage differences is crucial for safe and effective lighting solutions. ↩

Exploring safety standards ensures you choose compliant and reliable lighting options. ↩

Understanding MOL is essential for ensuring proper fit in fixtures, making this resource invaluable for both sales teams and customers. ↩

Knowing how to measure Maximum Diameter helps avoid fit issues, ensuring customer satisfaction and enhancing your expertise in lighting solutions. ↩

Explore this link to understand the applications and benefits of E12 Candelabra bases in lighting fixtures. ↩

Discover the advantages of E14 SES bulbs, including their efficiency and design, to enhance your lighting choices. ↩