You need to place a large order, and your top priority is getting the best unit price. But you know that with bulk purchasing, a small mistake in quality can multiply into a catastrophic, profit-destroying problem.

The smartest way to buy LED filament bulbs in bulk is to partner directly with a manufacturer. This approach provides the best price by eliminating middlemen, gives you direct control over quality specifications, and offers flexible options like scheduled deliveries and custom production runs.

I'll never forget a conversation I had with a potential new client, the owner of a lighting distribution company in the Netherlands. He came to us after a disastrous experience with a large order he had placed through a trading company. He had ordered 20,000 C35 candelabra bulbs. The price was fantastic, and the samples looked fine. But when the container arrived, the failure rate was over 10% right out of the box, and the color temperature varied wildly from bulb to bulb. The trading company was just a middleman; they couldn't help him. They had no control over the factory's production. He was stuck with a huge quantity of unsellable product. His story is a classic example of focusing only on the unit price while ignoring the much larger risks of bulk purchasing. It proves that the "smartest" way to buy is not about finding the cheapest quote; it's about choosing the sourcing method that gives you the most control and the least risk.

Should You Buy from a Wholesaler or a Trading Company?

When starting out, it seems logical to buy from a domestic wholesaler or a large trading company. They offer a wide catalog and seem simple to deal with. But is this convenience costing you more in the long run?

Wholesalers and trading companies are middlemen. While convenient for small quantities, their business model adds a significant price markup and separates you from the factory, giving you zero control over production quality, lead times, or the product's technical specifications.

For a professional buyer like Jacky, understanding the supply chain is critical. Let's define these two entities. A domestic wholesaler buys containers of products from various factories, warehouses them in your country (like the US or UK), and sells them in smaller quantities. They are a great option if you need 500 bulbs tomorrow. However, you pay a premium for that convenience and warehousing. A trading company, on the other hand, is a sourcing agent. They don't manufacture anything. They connect you with factories and handle communication. While they can be useful for finding suppliers, their primary goal is to make a margin on the transaction. They often steer you towards the factory that gives them a better deal, not necessarily the one with the best quality. In both cases, you are adding at least one, and sometimes two, layers of cost and communication between you and the people actually making your product. This creates a dangerous lack of transparency. When a problem occurs, as it did with my Dutch client, the middleman has no real power to fix it.

The Role of Middlemen in Bulk Purchasing

It's crucial to know who you are really buying from and what value they provide.

- Domestic Wholesaler1: Their value is local inventory and fast delivery for smaller quantities. Their business model is buying low in massive bulk from a factory and selling higher in smaller bulk to you. They are not a viable option for true, cost-effective bulk purchasing as their prices are fundamentally not factory-direct.

- Trading Company: Their value is in sourcing and communication, especially if you lack experience. However, they are a gatekeeper to the factory. You don't have a direct relationship with the engineering or quality control teams. This lack of direct access is a major liability on a large volume order.

| Sourcing Option | Price Structure | Quality Control | Best For... |

|---|---|---|---|

| Wholesaler | High (Includes their import, warehouse, and profit) | None. They sell what they receive. | Small, urgent orders. |

| Trading Company | Medium (Factory price + their commission) | Limited. They rely on the factory's QC. | Finding new factories (with caution). |

| Direct Manufacturer2 | Low (Factory-direct pricing) | Direct. You set the specs and get reports. | Serious bulk purchasing. |

For any significant volume, the added cost and risk of using a middleman almost always outweigh the convenience.

How Does Bulk Buying Magnify the Risks of Low Quality?

With a small order, a few faulty bulbs are an annoyance. But when you buy 10,000 units, even a tiny defect rate becomes a massive financial and logistical nightmare. How do you protect your investment?

In bulk buying, a low single-digit failure rate, which seems small, translates into hundreds or thousands of defective units. This creates huge costs in replacement products, shipping, labor for swap-outs, and severe damage to your brand's reputation for reliability.

Let's do some simple math. You're deciding between two factories for an order of 20,000 bulbs for a large commercial project. Factory A (a quality-focused manufacturer) has a documented failure rate of 0.5% in the first year and costs $2.50 per bulb. Factory B (a low-price-focused factory) costs $2.20 per bulb but has an actual failure rate of 3%. The $0.30 difference per bulb, or $6,000 on the total order, looks very tempting. But now let's calculate the cost of failure. With Factory A, you can expect about 100 failures. With Factory B, you're looking at 600 failures. Let's assume the cost to replace a single bulb (including labor and shipping a new one) is $15. The total failure cost for Factory A is 100 x $15 = $1,500. The total failure cost for Factory B is 600 x $15 = $9,000. Suddenly, the "cheaper" option has cost you an extra $1,500 and created five times the number of unhappy customers. This is the magnification effect. In bulk purchasing, the reliability and quality control of your supplier is more important than a small difference in the initial unit price.

Calculating the True Cost of a Bulk Order

Always look beyond the purchase order price and calculate the Total Cost of Ownership (TCO)3.

- Initial Purchase Cost: The unit price multiplied by the quantity. This is the most visible number.

- Cost of Failure4: (Quantity x Failure Rate) x (Cost of Replacement Bulb + Cost of Labor). This is the hidden number that can destroy your profit.

- Cost of Reputation: The unquantifiable but very real cost of your customers losing trust in your products. One bad project can lose you future business for years.

| Cost Factor | Factory A (Quality Focus) | Factory B (Low-Price Focus) |

|---|---|---|

| Order Size | 20,000 units | 20,000 units |

| Unit Price | $2.50 | $2.20 |

| Initial Cost | $50,000 | $44,000 |

| Failure Rate & Cost | 0.5% (100 failures) x $15 = $1,500 | 3% (600 failures) x $15 = $9,000 |

| Total Cost | $51,500 | $53,000 |

The "cheaper" supplier was actually $1,500 more expensive and created 500 more customer problems.

Why is Direct Factory Sourcing the Best Option for Volume Orders?

You've seen the risks of middlemen and low-quality suppliers. So, how does working directly with the factory solve these problems and provide the best value for your bulk purchases?

Sourcing directly from a manufacturer like Hongyu Bulb is the ideal solution because it offers the lowest possible price by removing all intermediaries, provides total transparency into quality control, and allows you to build a long-term relationship for better service and support.

When you establish a direct relationship with a manufacturer, you fundamentally change the nature of your purchasing. The conversation is no longer just about price; it's about partnership. First, pricing becomes transparent and fair. Our price is based on the actual cost of high-quality components, efficient labor, and our operational overhead. There are no hidden commissions or markups from a third party. This ensures you are getting the best possible price for the quality you specify. Second, you gain complete control over quality. You can talk directly to our engineering team about the specific driver you want to use or the CRI level you require for a project. We can provide you with quality control reports, testing data, and certifications. This transparency eliminates the risk of receiving a container of products that don't meet your standards. Finally, you build a relationship. We see you as a long-term partner, not a one-time transaction. This means we are invested in your success. We can work with you on production schedules, alert you to new technologies, and provide dedicated support if any issues arise. This level of control, transparency, and support is simply not possible when there is a middleman in between.

The Three Pillars of Direct Sourcing

These are the core advantages that make the direct model superior for bulk buying.

- Price Efficiency5: By removing markups from wholesalers and trading companies, more of your money goes directly into the quality of the product itself.

- Quality Assurance6: You have a direct line of communication to the people making the product. You can dictate specifications, demand test reports, and have confidence in the consistency of your large order.

- Logistical Control: You can work with the factory to plan production and shipping schedules that align with your needs, enabling better inventory management and reducing carrying costs.

| Benefit | With a Middleman | Direct from Manufacturer |

|---|---|---|

| Pricing | Inflated; includes hidden margins. | Transparent and based on true cost. |

| Quality Control | Indirect and unreliable. | Direct, specific, and verifiable. |

| Communication | Slow and filtered. | Fast, clear, and with technical experts. |

| Relationship | Transactional. | Partnership-focused. |

For the volume buyer, going direct is the only way to truly secure your investment.

What Kind of Bulk Orders Unlock the Best Value?

You're ready to work directly with a manufacturer. Now, how can you structure your orders to get the most competitive pricing and the best service? It’s more than just asking for a quote on a large number.

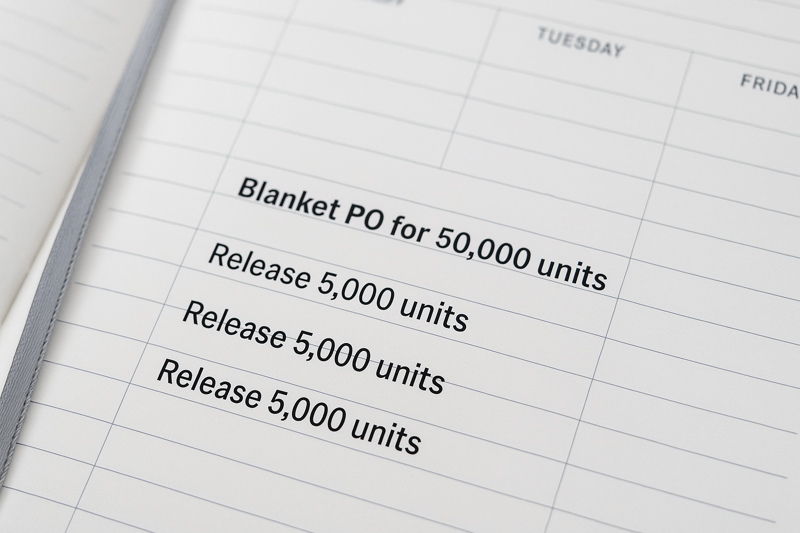

To unlock the best value, move beyond simple large orders. Use strategic tools like Blanket Purchase Orders (BPOs) with scheduled releases, commit to an annual volume forecast, and collaborate with the factory on cost-saving measures like optimized packaging.

As a manufacturer, our biggest enemy is unpredictability. A large, one-time order is good, but a predictable, long-term partner is even better. When you come to us with a strategic plan, it allows us to optimize our own operations, and we share those savings with you. For example, instead of placing a single order for 10,000 bulbs, consider a Blanket Purchase Order for 60,000 bulbs for the entire year, with scheduled "releases" of 5,000 bulbs each month. This gives you several advantages: you lock in the best possible price based on the 60,000-unit volume, you don't have to take all the inventory at once (which is great for your cash flow and warehouse space), and you guarantee your supply. For us, it's a huge benefit because we can plan our component purchasing and production schedules far in advance, reducing our costs. Another powerful strategy is to provide an annual forecast. If you can confidently tell us you'll need approximately 100,000 units of a certain model over the next 12 months, we can treat you as a high-volume client from day one. This proactive, partnership-based approach changes the pricing conversation and unlocks a level of value that simple haggling can never achieve.

Strategic Bulk Buying Methods

Choose the method that best fits your business model.

- Minimum Order Quantity (MOQ)7: The starting point for bulk pricing. Meeting the factory's MOQ gets you out of the sample price and into wholesale pricing.

- Large One-Time Order: Good for project-based needs. A large quantity (e.g., a full container) will get you a very competitive price.

- Blanket Purchase Order (BPO): The best of both worlds. You commit to a high volume to get the best price, but take delivery in smaller, scheduled shipments.

- Annual Volume Commitment8: A strategic agreement. You commit to a total purchasing volume for the year, unlocking top-tier pricing on all your orders, large and small.

| Order Type | Best For... | Key Benefit |

|---|---|---|

| MOQ Order | Testing a new supplier or product. | Access to factory-direct pricing. |

| Large Project Order | Fulfilling a single large installation. | Excellent unit price for that specific project. |

| Blanket PO | Core products with steady demand. | Locks in low price, aids cash flow. |

| Annual Commitment | Distributors with a full product line. | Secures best-tier pricing across all products. |

Being a strategic partner, not just a customer, is the final key to getting the best possible deal on your bulk purchases.

Conclusion

The smartest bulk purchasing strategy minimizes risk and maximizes value. This is achieved by bypassing middlemen and building a transparent, long-term partnership directly with a reliable and efficient manufacturer.

Understanding the pros and cons of Domestic Wholesalers can help you make informed purchasing decisions. ↩

Exploring resources on finding Direct Manufacturers can lead to better pricing and quality control for your bulk orders. ↩

Understanding TCO helps you make informed purchasing decisions, ensuring long-term savings and efficiency. ↩

Calculating Cost of Failure is crucial for identifying hidden expenses that can impact your overall profitability. ↩

Understanding price efficiency can help you maximize your budget and improve product quality. ↩

Exploring quality assurance in direct sourcing ensures you maintain high standards and reliability in your purchases. ↩

Understanding MOQ can help you negotiate better prices and optimize your purchasing strategy. ↩

Exploring this concept can reveal how to secure the best pricing and enhance your business's purchasing power. ↩