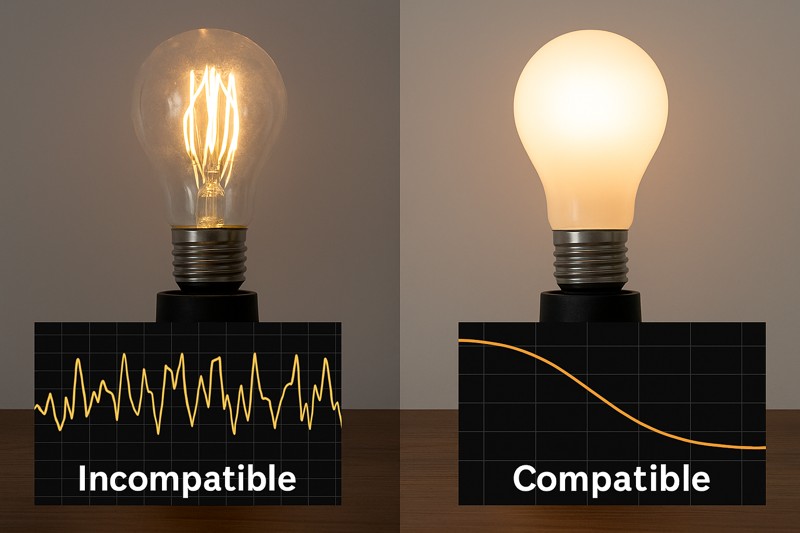

You've installed beautiful dimmable LED filament bulbs for a high-end project, but they're a disaster. They flicker, buzz, and won't dim smoothly, making the entire installation feel cheap and unprofessional.

Dimming problems are almost always caused by an incompatibility between the LED bulb's internal driver and the wall dimmer switch. Using a modern dimmer designed for LEDs (trailing-edge) or a bulb with a high-quality driver tested for broad compatibility is the key to smooth, silent performance.

I once had a frantic call from Jacky, a key client of mine in the United States. He was wrapping up a lighting installation for a new, very exclusive restaurant. The designer's vision was all about creating a warm, intimate atmosphere with precise mood lighting. Jacky had sourced "dimmable" A19 LED filament bulbs from another supplier to complete the job. On paper, everything was perfect. But at the grand opening preview, the owner went to dim the lights for the evening service and the entire room erupted in a chaotic strobe effect, accompanied by an audible buzz from every fixture. It was a complete nightmare. Jacky's reputation was at stake, and the restaurant's multi-million dollar ambiance was ruined. He called me in a panic, and I explained that "dimmable" is one of the most misunderstood words in the lighting industry. The bulb is only half of the equation; the dimmer is the other half, and if they don't speak the same language, the result is chaos.

Aren't All 'Dimmable' LEDs Supposed to Work with All Dimmers?

You purchased bulbs clearly labeled "Dimmable," so you assumed they would work with any dimmer switch. Now they are flickering or not working at all, and you're stuck with useless inventory or a major installation headache.

No. "Dimmable" simply means the bulb's driver is designed to interpret a dimming signal. However, it does not guarantee compatibility with every type of dimmer. The technology inside the dimmer switch must match the technology inside the bulb's driver.

This is the fundamental problem Jacky faced at the restaurant. His electrical contractor had installed standard, inexpensive dimmers throughout the building. These dimmers were never designed to handle the sophisticated, low-power electronics of an LED bulb. Understanding the two main types of dimmers is the first step to solving nearly every dimming issue a buyer, installer, or owner will ever face.

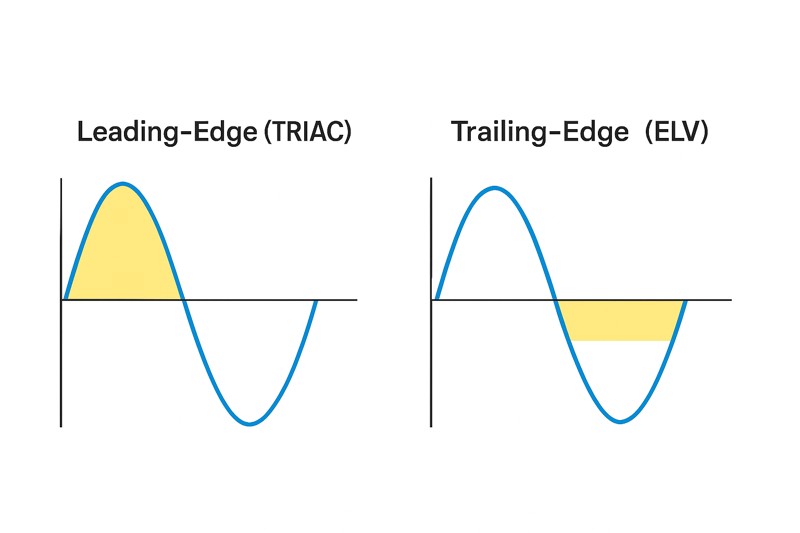

The Old World: Leading-Edge (TRIAC) Dimmers1

These are the traditional dimmers that have been used for decades. You'll find them in most older buildings. They were designed for one purpose: dimming high-power incandescent bulbs. They work by chopping off the "leading edge" of the AC power sine wave. An incandescent bulb is just a simple resistor (a glowing wire), so it doesn't care how choppy the power is; less power equals less light. However, LEDs are complex electronic devices. When a leading-edge dimmer sends this brutally chopped signal to an LED driver2, the driver struggles to interpret it. This mismatch is what causes flickering and buzzing. These dimmers also have a high minimum load requirement3, often 25-40 watts. A single 5-watt LED bulb doesn't draw enough power for the dimmer to even "see" it, leading to erratic behavior.

The Modern Solution: Trailing-Edge (ELV) Dimmers4

Modern dimmers, often called Electronic Low Voltage (ELV) or "reverse-phase" dimmers, were specifically designed for low-power electronic loads like LED drivers. Instead of chopping the front of the power wave, they smoothly cut off the "trailing edge." This method is much gentler on the LED's electronics, resulting in smooth, silent dimming without flicker. They have a very low minimum load, so they work perfectly even with a single LED bulb. While they are slightly more expensive, their performance is vastly superior and they are the professional standard for any new LED installation.

| Feature | Leading-Edge (TRIAC) Dimmer | Trailing-Edge (ELV) Dimmer | Why It Matters for Your Project |

|---|---|---|---|

| Compatibility | Incandescent bulbs; some compatible LEDs | All LEDs, CFLs, and electronic transformers | ELV is the universal, future-proof choice for LED lighting. |

| Minimum Load | High (e.g., 25W+) | Very Low (e.g., 1W or less) | Crucial for dimming a single or small number of low-wattage LED bulbs. |

| Performance | Can cause buzzing, humming, and flicker | Smooth, silent, and stable dimming | Guarantees the quality feel your client expects in a high-end installation. |

| Cost | Inexpensive | Moderately Priced | The small extra cost prevents expensive callbacks and client complaints. |

For Jacky's restaurant, the solution was clear, though painful: they had to replace all the cheap TRIAC dimmers with modern ELV dimmers. The problem vanished instantly.

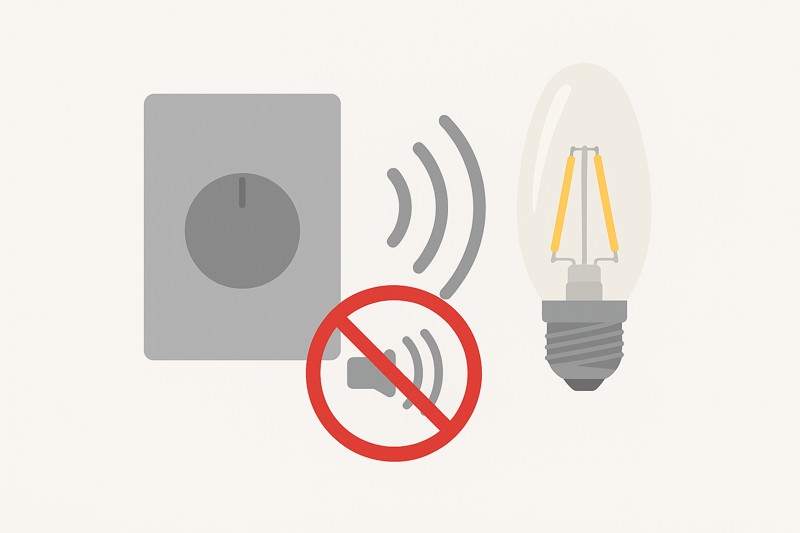

Why Do My LEDs Buzz or Hum When I Dim Them?

The lights are dimming, but they're making an annoying buzzing sound. In a quiet, intimate setting like a fine dining restaurant or a master bedroom, this electrical hum completely ruins the atmosphere.

The buzzing sound is a physical vibration of components inside either the dimmer switch or the bulb's driver. It is caused by the harsh, chopped-up power signal from an incompatible leading-edge (TRIAC) dimmer, which makes the electronics vibrate.

That audible buzz was the second problem in Jacky's restaurant project. Even in the areas where the lights weren't flickering wildly, there was a persistent low hum that was unacceptable for a fine dining space. The owner was rightly concerned that it would distract his patrons. The source of this noise is purely mechanical, triggered by electrical incompatibility. Think of it like hitting a bell with a hammer. A clean power signal is like a soft push, but a choppy TRIAC signal is like a rapid series of sharp taps that makes components resonate and "ring."

The Science of the Buzz

The primary culprit inside the LED bulb's driver is a component called an inductor. An inductor is a tightly wound coil of wire that helps to smooth and regulate the flow of electricity. When the abrupt, high-frequency voltage changes from a leading-edge dimmer pass through this coil, it causes a phenomenon called "magnetostriction5"—the inductor physically contracts and expands minutely, vibrating at the frequency of the electrical mains (60 times per second in the US). This vibration is what you hear as a 60Hz or 120Hz hum. Loosely wound or low-quality inductors are much more susceptible to this vibration. The TRIAC component in the dimmer switch itself can also vibrate and buzz for the same reason.

How Quality Drivers Solve the Buzz

At Hongyu Bulb, engineering for silent dimming is a top priority. A cheap driver uses the most basic components with no thought given to noise. Our approach is more robust, focusing on both compatibility and physical construction.

- Driver Compatibility Testing6: Our R&D department maintains a library of the most popular dimmer switches from major brands in our main export markets, like Lutron and Leviton in the United States. We test our driver designs on a wide range of both leading-edge and trailing-edge models to optimize their performance and eliminate buzz across as many systems as possible.

- Component Encapsulation (Potting)7: We don't just use better inductors; we physically secure them. Critical components in our premium drivers are "potted"—encased in a solid block of epoxy resin. This potting material completely surrounds the component, absorbing any micro-vibrations and preventing them from creating audible noise. It acts like a shock absorber for the electronics.

- Advanced Driver Topologies8: For our highest-end bulbs, we use more sophisticated driver designs, like Constant Current Reduction (CCR). Instead of rapidly chopping the power on and off, a CCR driver smoothly reduces the electrical current sent to the LEDs. This is the ultimate form of dimming and is inherently silent and flicker-free because it doesn't create the harmonic distortion that causes buzzing.

By focusing on these engineering details, we build bulbs that are not just "dimmable," but are pleasantly dimmable.

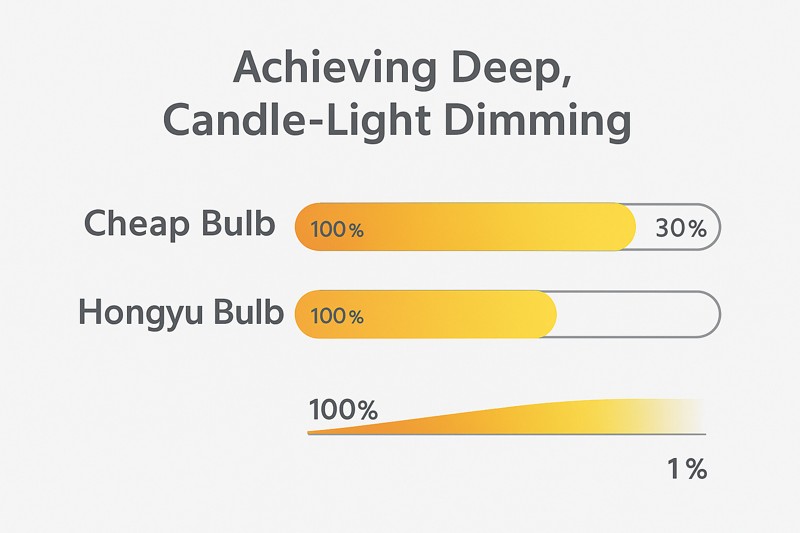

What Does 'Dimming Range' Mean and Why Don't My Bulbs Dim Low Enough?

You specified dimmable lights to create a warm, candle-like glow. But when you try to dim them down, they abruptly turn off at 20% or 30% brightness, completely failing to achieve the intimate mood you wanted.

The dimming range is the span from a bulb's maximum brightness to its minimum stable brightness. A limited range is caused by the bulb's driver needing a minimum amount of power to stay on, a problem often made worse by the dimmer's minimum load requirement.

This is often the final hurdle in a dimming project. The lights don't flicker, they don't buzz, but they just don't get low enough. For applications in hospitality, high-end residential, and theaters, achieving a "deep dim" down to 5% or even 1% is essential. A bulb that cuts out at 30% is a functional failure in these environments. This limitation is a direct result of compromises made in the internal driver electronics to save cost.

The Minimum Power Problem

An LED driver is a complex electronic circuit; like any electronic device, it requires a certain amount of power just to keep itself running. As you lower the dimmer, you are reducing the power sent to the bulb. At a certain point, the power level becomes too low for the driver's circuit to function. Rather than continuing to dim, the driver's control IC simply shuts off, and the light goes out abruptly. This is the "cut-out" point.

The problem is magnified by the minimum load requirement of the dimmer itself, especially on older TRIAC systems. If you have only a few LED bulbs on a circuit, the total power draw might fall below the dimmer's minimum load threshold as you dim down, causing the dimmer to behave erratically and shut off the output to the bulbs.

Engineering for a Deep Dimming Curve

Achieving a deep dimming range from 100% down to 1% is a hallmark of a premium-quality LED driver. It requires more sophisticated engineering and better components that can operate stably at very low power levels.

- Stable Low-Power Operation: We design our driver circuits with control ICs that are specifically chosen for their ability to function at extremely low power inputs. We use higher-quality power regulation components that don't need as much overhead power to stay active.

- Logarithmic Dimming Curve: Human perception of light is not linear; it's logarithmic. A drop from 100% to 50% brightness looks like a small change, but a drop from 10% to 5% looks like a huge change. Cheap drivers use a linear dimming curve, which means most of the dimming action happens at the top end, and the bottom end feels abrupt. We program our drivers with a logarithmic curve that matches human eye perception, delivering a smooth, natural, and continuous dimming experience all the way down to the lowest levels.

- Dim-to-Warm Technology: For the ultimate atmospheric lighting, we offer "Dim-to-Warm" filament bulbs. These bulbs not only get dimmer as you lower the power, but their color temperature also gets warmer, perfectly mimicking the behavior of an incandescent bulb. The light shifts from a bright 3000K down to a cozy, candle-like 1800K. This is achieved by incorporating amber-colored LED chips onto the filament that activate only at low power levels, and it requires a highly advanced driver to manage the color mixing smoothly.

When you need to guarantee a specific atmosphere for your client, you cannot leave the dimming range to chance. You need a supplier who understands the nuances of deep dimming and can provide a bulb engineered to deliver it.

Conclusion

Successful LED dimming is a system of a quality bulb and a compatible dimmer. Choosing bulbs with drivers proven to be quiet, stable, and broadly compatible eliminates the flicker, buzz, and frustration.

Understanding TRIAC dimmers helps in recognizing their limitations with modern lighting, ensuring better choices for your projects. ↩

Understanding LED drivers enhances your knowledge of lighting systems, ensuring compatibility and performance in your designs. ↩

Learning about minimum load requirements is crucial for selecting the right dimmer, especially for low-wattage LED bulbs. ↩

Exploring ELV dimmers reveals their benefits for LED lighting, ensuring optimal performance and satisfaction in installations. ↩

Understanding magnetostriction can help you grasp how LED bulbs produce sound and improve your lighting choices. ↩

Explore how Driver Compatibility Testing ensures optimal performance and eliminates buzzing in LED bulbs. ↩

Learn about Component Encapsulation and how it enhances the durability and performance of LED drivers. ↩

Discover how Advanced Driver Topologies contribute to silent and flicker-free LED lighting solutions. ↩