You've sold a batch of your finest LED filament bulbs, but now you're getting angry emails from customers. They complain about flickering, buzzing, and bulbs that die within weeks, destroying their trust in your product and your brand's reputation for quality.

Most flickering and premature failures in new LED filament bulbs stem from installation mismatches, especially with old dimmer switches. Proper installation requires pairing the bulb with a modern, LED-compatible dimmer and ensuring the light fixture provides adequate ventilation to prevent overheating.

I remember a major project we supplied for a hotel renovation in the Netherlands. The client, a very demanding project manager we'll call Jacky, ordered ten thousand of our best dimmable B22 filament bulbs for the guest rooms. Two weeks after the installation, he called me in a fury. "Wallson, your bulbs are garbage! Half of them are flickering like a horror movie!" he said. My heart sank. A failure on this scale could ruin us. I flew out to Amsterdam the next day. As I walked into the first room, I didn't look at the bulb; I looked at the switch on the wall. It was a classic, heavy-duty rotary dimmer from the 1990s. They had replaced the 60-watt incandescent bulbs with our 7-watt LEDs, but they never touched the controls. The dimmers were designed for a high electrical load and were completely confused by the low-wattage LEDs, causing the flicker. We had to have a difficult conversation, but we worked with him to source modern, trailing-edge dimmers. Once they were installed, the problem vanished completely. It was a powerful lesson: a premium bulb is only as good as the system it's installed in.

Why is a Dimmer Switch the #1 Enemy of LED Filament Bulbs?

You sold high-quality, fully "dimmable" bulbs, but the customer insists they flicker and buzz terribly when dimmed. They blame your product, demand a full refund, and you're left wondering why a feature you paid for is failing so spectacularly.

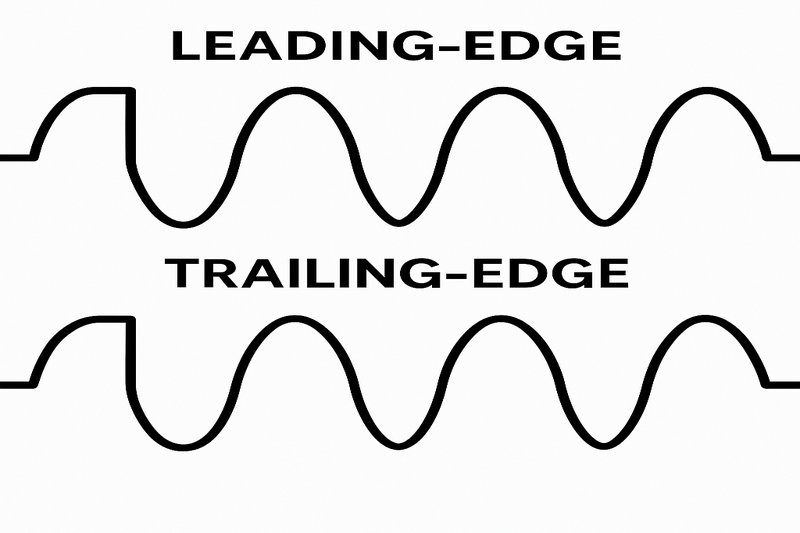

Old "leading-edge" dimmers, designed for the high power draw of incandescent bulbs, are electronically incompatible with low-wattage LEDs. Successful, flicker-free dimming requires a modern "trailing-edge" or C.L (Compatible Lamp) type dimmer specifically rated for LED and CFL loads.

This is the single most common installation problem we see, and it's rooted in a technology change. A traditional incandescent bulb is a very simple device: a wire that gets hot. It doesn't care how it gets its electricity. Old dimmers, called leading-edge or TRIAC dimmers, worked by chopping off the very beginning of the AC power wave. To function correctly, they needed to see a high electrical load—typically 40 watts or more. An LED filament bulb, however, is a sophisticated electronic device with a driver (a miniature computer) in its base. When you connect a 7-watt LED bulb to a dimmer expecting a 40-watt load, the dimmer's circuit becomes unstable. It can't "see" the bulb properly. This instability is what causes the bulb to flicker, strobe, or buzz. Modern LED-compatible dimmers use a different technology called trailing-edge or reverse-phase dimming. These are designed to work perfectly with the sensitive electronics and low power draw of LEDs, allowing for smooth, silent, and flicker-free dimming all the way down to very low light levels.

A Quick Guide to Dimmer Compatibility

Educating your customers on this point is crucial for their success. Here’s a simple comparison to help them identify the right hardware.

| Dimmer Type | Incandescent (Leading-Edge) | LED-Compatible (Trailing-Edge / C.L)1 |

|---|---|---|

| Technology | TRIAC / Forward-Phase | Reverse-Phase / MOSFET |

| Designed For | High-wattage resistive loads (e.g., 60W bulb) | Low-wattage electronic loads (e.g., 7W LED) |

| Performance with LEDs | Causes flickering, buzzing, strobing, premature failure.2 | Provides smooth, silent, and stable dimming. |

| How to Identify | Often older, rotary knob style. Not explicitly marked for LEDs. | Labeled "C.L™," "LED+," or "LED/CFL Compatible" on the packaging. |

When your clients report flickering, the first question should always be: "What is the exact model of the dimmer switch you are using?" This simple diagnostic question can save everyone from a costly and unnecessary product return.

Can the Wrong Fixture Secretly Destroy Your LED Bulbs?

A customer complains that your bulbs, which you guarantee for 15,000 hours, are burning out in less than a year. They're especially failing in their new bathroom vanity lights and their enclosed outdoor porch fixtures. Are you selling a defective product?

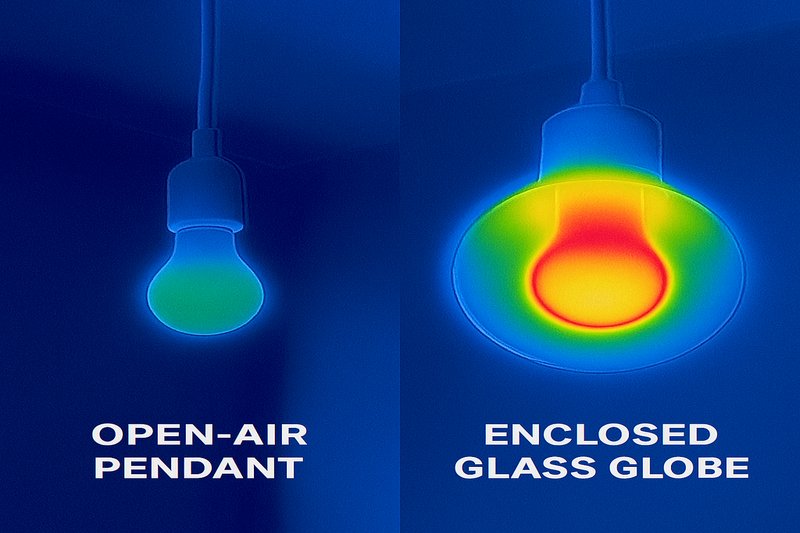

Heat is the primary killer of LED electronics. An enclosed fixture without airflow acts like an oven, trapping heat and cooking the sensitive driver components in the bulb's base. For longevity, you must use bulbs specifically listed as "Enclosed Fixture Rated" for these applications.

This is another critical installation factor that is often overlooked. Incandescent bulbs were incredibly inefficient; 90% of their energy was wasted as heat. They were designed to operate at very high temperatures. LED filament bulbs are the exact opposite. They are highly efficient, but the small amount of heat they do generate must be dissipated away from the sensitive electronic driver located in the base. If the heat cannot escape, its temperature will rise rapidly, exceeding the operating limits of the electronic components and causing them to fail prematurely. A fixture that is fully sealed—like a "jelly jar" light, a glass globe without ventilation holes, or some types of recessed can lighting—is a death trap for a standard LED bulb. Bulbs that are "Enclosed Fixture Rated" are engineered with more robust, higher-temperature-rated electronic components and advanced thermal management to withstand these harsher conditions. Using a standard bulb in a sealed fixture will always void its warranty and lead to early failure.

Understanding Location and Durability Ratings

To professionalize your product offerings, you need to match the bulb's rating to the fixture's location.

| Rating | Description | Typical Use Case | Installation Requirement |

|---|---|---|---|

| Open Fixture | Standard bulb. Requires free air circulation. | Table lamps, chandeliers, open pendants. | Must not be used in sealed fixtures. |

| Enclosed Fixture Rated3 | Built with high-temperature components. | Recessed cans, sealed globes, any fixture that traps heat. | Required for any airtight or enclosed luminaire. |

| Damp Rated4 | Can withstand moisture and humidity, but not direct water. | Bathrooms (outside the shower), covered porches. | Use in locations with high humidity. |

| Wet Rated | Fully sealed against direct contact with water. | Outdoor landscape lighting, exposed signs, shower downlights. | Required for any fixture exposed to rain or water. |

By asking your clients about the intended fixture type—open, enclosed, or outdoor—you can guide them to the correct, longer-lasting product and prevent the inevitable complaints that arise from using the wrong bulb in the wrong place.

Is a Simple Mismatch Making Your Installation Look Unprofessional?

Your customer installed the bulbs, but the lighting looks "off." Some bulbs hang too low in the pendants, others won't fit inside the glass shade at all, and the light on the table is shaped weirdly. The installation is a functional success but an aesthetic failure.

Proper installation is also about physical and aesthetic compatibility. You must verify the bulb's physical dimensions (MOL and diameter) against the fixture's constraints and choose a bulb shape that complements the fixture's design and intended light distribution.

After solving the technical issues of dimmers and heat, we must address the final details that separate a merely functional installation from a beautiful one. I've seen clients order thousands of gorgeous T9 tubular bulbs for a fixture that was designed for a round G25 globe bulb. The result was a visual disaster. Before any large-scale installation, you must consider the physical fit. Check the Maximum Overall Length (MOL) and the maximum diameter of the bulb against the interior space of the fixture's shade or housing. Will it fit? And more importantly, will it look right? A tiny C7 candelabra bulb will look lost and ridiculous in a large drum pendant. Furthermore, as we've discussed before, the shape of the bulb dictates the shape of the light it casts. A long tubular bulb will cast an oblong pool of light, perfect for a rectangular dining table. A round globe bulb will cast a perfectly circular pool of light. Installing the wrong shape can ruin the intended lighting effect of a high-end fixture.

Pre-Installation Compatibility Checklist

Ensure your clients or their installers run through this final checklist before committing to a full installation.

| Check Point | Question to Ask | Why It Matters |

|---|---|---|

| 1. Voltage5? | Does the bulb's voltage (e.g., 120V or 220-240V) match the building's electrical supply? | Prevents instant burnout and potential fire hazards. |

| 2. Base Type6? | Does the base (E26, E27, B22, etc.) match the fixture's socket? | Seems obvious, but it's a common and costly shipping error. |

| 3. Physical Size? | Do the bulb's MOL and diameter fit within the fixture's shade with adequate clearance? | Prevents returns due to a bulb that simply won't fit or looks awkward. |

| 4. Aesthetic Shape? | Does the bulb's shape (Globe, Edison, Tubular) complement the fixture and the desired light pattern? | Ensures a high-end, professional aesthetic result, not a mismatched look. |

By guiding your customers through these "final fit" details, you are not just a supplier; you become a trusted lighting consultant, adding value that prevents errors and elevates the quality of the final project.

Conclusion

Proper installation is not just about twisting in a bulb. It's about ensuring compatibility with dimmers, fixtures, and the environment. Guiding your clients on these details protects your product's performance and your brand's reputation for excellence.

Explore the advantages of LED-Compatible dimmers for optimal performance and energy efficiency. ↩

Understanding these issues can help you troubleshoot and improve your lighting experience. ↩

Explore this link to understand the benefits and applications of Enclosed Fixture Rated bulbs for optimal lighting solutions. ↩

Learn about Damp Rated fixtures to ensure safety and longevity in humid environments, enhancing your lighting choices. ↩

Understanding voltage compatibility is crucial to prevent burnout and ensure safety in installations. ↩

Matching base types avoids costly shipping errors and ensures proper functionality of the lighting. ↩