You've recommended beautiful LED filament bulbs for a client's stylish new retail space or gallery. But now they're complaining that the lighting looks messy, doesn't highlight their products, and some bulbs are even failing after just a few months.

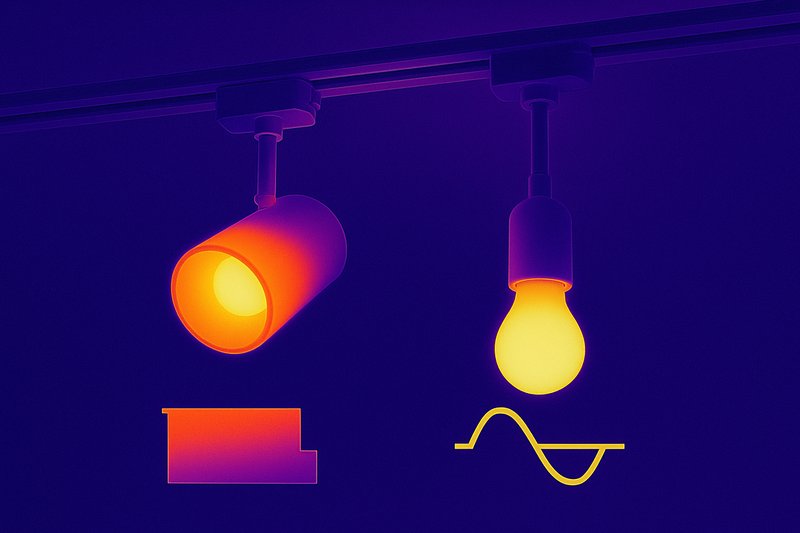

This mismatch occurs because omnidirectional filament bulbs are designed for ambient, room-filling light, while track lighting is for directional accent light. Furthermore, the small, enclosed design of many track heads can trap heat, causing premature bulb failure.

I remember a project we supplied for a client, a product manager we'll call Jacky. He was outfitting a chain of boutique hotels in the United States and loved the warm, vintage look of our amber-coated ST64 Edison bulbs. He ordered thousands to be used everywhere, including the track lighting systems in the hotel corridors meant to highlight artwork on the walls. A month after the grand opening, I got a call. It wasn't about flickering or failures, but about aesthetics. "Wallson, the owner is unhappy," Jacky said, sounding defeated. "The light on the paintings is terrible. It's weak, and there's a distracting glare in the hallway. It looks cheap." I asked for photos, and the problem was immediately obvious. They had put a bulb designed to light up a whole room (omnidirectional) into a fixture designed to act like a sniper rifle (directional). The track head couldn't control the light, so it just spilled out everywhere, creating a flat, unimpressive wash. We had to work with him to replace the track head bulbs with proper LED PAR20 lamps. It was a clear lesson: even a high-quality bulb becomes the wrong product when used for the wrong purpose.

Are Your Track Heads Secretly Cooking Your Bulbs?

Your client reports that the filament bulbs installed in their track system are burning out at an alarming rate, far short of their 15,000-hour rated life. You're now facing warranty claims and your reputation for quality is at stake.

Heat is the primary killer of LEDs. Many track heads are small and unventilated, creating an oven-like environment that overheats the bulb's sensitive electronic driver. Continuous overheating leads to rapid component degradation and inevitable premature failure.

This is the most critical technical issue when specifying filament bulbs for track lighting. People forget that while LEDs are "cool" to the touch compared to incandescents, they still produce heat that must be managed. This heat is generated by the electronic driver, a tiny circuit board packed into the bulb's base. For the bulb to reach its rated lifespan, this heat must dissipate into the surrounding air through convection. A standard track head, especially a compact, cylindrical "can" style, completely seals off the base of the bulb. There is no airflow. The heat generated by the driver has nowhere to go, so the internal temperature of the bulb's base can skyrocket, far exceeding the design limits of the electronic components. This constant, excessive heat literally cooks the capacitors, resistors, and integrated circuits, causing them to fail. It's not a matter of if they will fail, but when—and it will be much, much sooner than you promised your customer. Even if a bulb is officially rated as "Enclosed Fixture Rated," this rating is often based on larger fixtures like a recessed can or a sealed glass globe, which have more internal air volume and surface area to dissipate heat than a tiny, cramped track head.

A Buyer's Guide to Thermally Safe Track Heads

Choosing the right hardware is essential to prevent these thermal failures1. You must guide your clients to select fixtures that prioritize ventilation2 over compact aesthetics.

| Track Head Style | Thermal Performance | Best Use Case with Filament Bulbs | Risk Factor |

|---|---|---|---|

| Enclosed Canister | Very Poor. Traps all heat around the bulb's base. | Not a good choice for any standard LED filament bulb. | High Risk of Failure |

| Open Gimbal / Ring | Good. Allows for significant airflow around the entire bulb. | Suitable for smaller A19 or G25 style filament bulbs where ambient light is acceptable. | Low Risk |

| Pendant Drop Adapter | Excellent. The bulb hangs in open air, completely unimpeded. | The ideal solution for showcasing decorative filament bulbs (G40, ST64, T9). | Very Low Risk |

| Baffled/Shrouded | Poor to Mediocre. Partially restricts airflow. | Should be avoided unless specifically designed with ventilation for LEDs. | Medium to High Risk |

When a customer plans to use our filament bulbs in a track system, my first question is always, "Can you show me a picture of the track head?" This simple step prevents the vast majority of future heat-related failures and warranty claims.

Why Can't Your Filament Bulbs Create a Spotlight?

The client wanted to illuminate specific objects—a mannequin in a store, a piece of art, a menu on a wall—but the light from the filament bulb is flat, weak, and creates a distracting glare for anyone walking by. Why can't it create a sharp, focused beam?

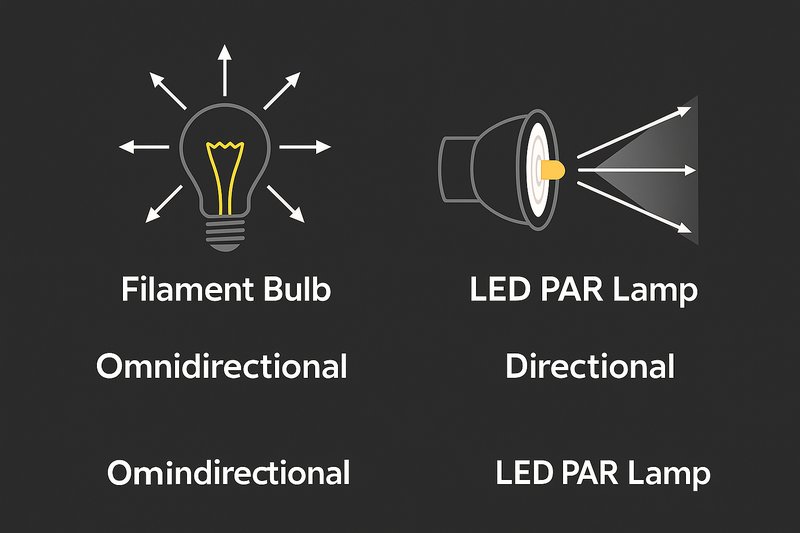

Filament bulbs are omnidirectional light sources, radiating light in a 360-degree sphere. Track lighting requires a directional source with internal optics (reflectors and lenses) to collimate light into a controlled beam. You cannot force an omnidirectional bulb to be directional.

This is a fundamental concept in lighting design that is often misunderstood. The beautiful, exposed LED "filaments" are designed to mimic a classic incandescent bulb, which means they are designed to throw light equally in all directions. This is perfect for a table lamp, a chandelier, or a pendant, where the goal is general, ambient illumination to make a space feel bright and welcoming. Track lighting has the opposite purpose. Its job is to create contrast, to draw the eye to specific points of interest by making them significantly brighter than their surroundings. This is called accent lighting or task lighting. To achieve this, a proper track light bulb (like a PAR, BR, or MR type) is engineered as a complete optical system. The light from the LED chips is captured by a purpose-built reflector and then focused through a lens to create a specific beam angle, measured in degrees (e.g., a 15° spot or a 40° flood). When you place an omnidirectional filament bulb inside a track head, you have no control. The track head itself has no optics; it's just a housing. 90% of the light produced by the bulb doesn't go forward; it spills out the sides and back, creating wasted light and ugly glare. The small amount of light that does go forward is unfocused and weak, failing to create the desired "punch" or contrast.

Matching the Bulb to the Lighting Task

Educating your client on the three layers of lighting design will help them select the right product and achieve a professional result.

| Lighting Layer | Purpose | Ideal Bulb Type for Track Lighting | Why Filament Bulbs are a Poor Fit |

|---|---|---|---|

| Ambient Lighting | Provides overall, general illumination for a room. | Not the primary job of track lighting. Better served by pendants, chandeliers, or recessed downlights. | Filament bulbs are ambient sources, but using them in a track system for this purpose is an inefficient and often unattractive solution. |

| Task Lighting3 | Provides focused light for a specific activity (e.g., reading, food prep). | LED PAR or BR series4 with a medium beam angle (25°-40°). | The light is too diffuse and unfocused to properly illuminate a task area. |

| Accent Lighting | Creates visual interest by highlighting objects (art, products, architecture). | LED MR16 or PAR series with a narrow beam angle (10°-25°). | Completely ineffective. They cannot create the sharp contrast or focused beam needed to make an object "pop." |

The only appropriate application for a filament bulb in a track system is decorative. When used with a pendant drop adapter, the bulb itself becomes the object of interest, appreciated for its aesthetic form rather than its lighting function.

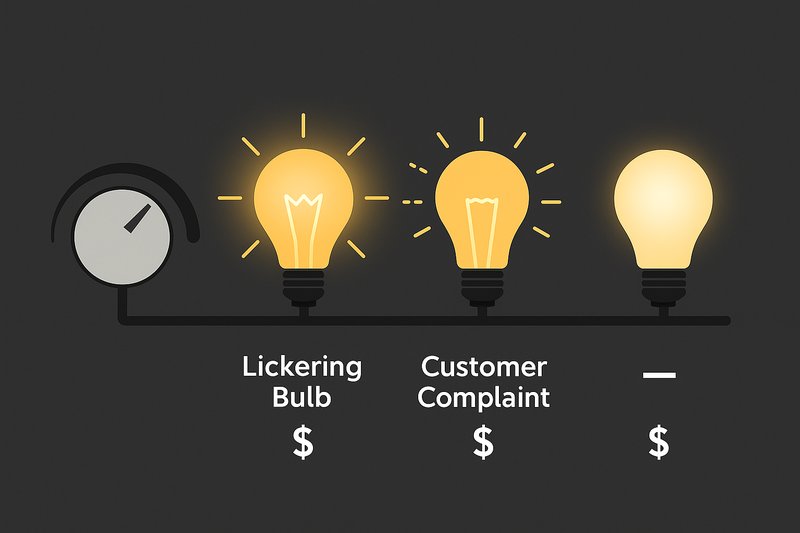

How Do You Dim Multiple Filament Bulbs on One Track Circuit?

A client has installed ten of your dimmable filament bulbs on a single track controlled by one new LED dimmer. When they dim the lights, some bulbs flicker, some buzz, and others don't dim smoothly with the rest. What is causing this inconsistent and unprofessional result?

Inconsistency arises from "tolerance stacking" in the bulb drivers and dimmer load issues. A dimmer's performance—especially its minimum load—is critical when controlling many low-wattage bulbs. For best results, use a high-quality dimmer and bulbs from the exact same manufacturing batch.

This is an advanced problem that often stumps even experienced installers. We've already established that you need a modern, LED-compatible (trailing-edge) dimmer. However, when you connect multiple bulbs to that one dimmer, new complexities emerge. The first is minimum load. A good LED dimmer might have a minimum load requirement of 10 watts. If you are using ten 7-watt bulbs, your total load is 70 watts, which is well above the minimum, so that's fine. But what if the client wants to use tiny 1.5-watt T6 candelabra bulbs? Ten of those is only 15 watts. On a long track run with potential voltage drop, the dimmer might struggle to maintain control of such a low load, leading to flickering at the bottom end of the dimming range. The second, more subtle problem is tolerance stacking. The electronic driver in every single LED bulb is slightly different due to minuscule manufacturing variations in its components. This means one bulb's driver might interpret the dimmer's signal slightly differently than the one next to it. When dimming a single bulb, this tiny variation is unnoticeable. But when you have ten bulbs on one track, these tiny variations add up. You might see one bulb start dimming slightly before the others, or another one that flickers at 20% brightness while the rest are stable. This is why, for large professional installations, it is absolutely critical that all bulbs come from the same production run to ensure the driver components are as closely matched as possible.

Best Practices for Multi-Bulb Track Dimming

| Factor | Best Practice | Reasoning |

|---|---|---|

| Dimmer Selection | Choose a high-quality C.L dimmer5 with an adjustable low-end trim. | An adjustable trim allows the installer to set the minimum dimming level, preventing flickering when the lights are very low. |

| Load Calculation | Ensure the total wattage of all bulbs is well above the dimmer's stated minimum load and below its maximum LED load. | Avoids operational instability and prevents overloading and damaging the dimmer. |

| Bulb Sourcing | For any single circuit, order all bulbs at once from the same supplier. | Minimizes driver variations ("tolerance stacking") for more uniform dimming performance across all bulbs. |

| Voltage Drop | On very long track runs (over 15 meters), consider using a heavier gauge wire or a second power feed. | Prevents the bulbs at the end of the line from receiving less voltage, which can affect their brightness and dimming consistency. |

By advising your clients on these four points, you can help them achieve the smooth, consistent, and professional dimming performance they expect.

Conclusion

To succeed with filament bulbs in track lighting, you must prioritize heat management with open fixtures, respect their purpose as ambient sources, and carefully manage multi-bulb dimming circuits. Guide your clients correctly to ensure a beautiful, lasting installation.

Understanding thermal failures can help you choose the right lighting fixtures and avoid costly mistakes. ↩

Exploring the importance of ventilation in lighting design can enhance your knowledge and improve your lighting choices. ↩

Explore this link to understand how to effectively illuminate specific activities with the right lighting solutions. ↩

Discover the advantages of using LED PAR or BR series bulbs for focused lighting tasks and their benefits in energy efficiency. ↩

Understanding C.L dimmers can help you choose the right one for optimal dimming performance. ↩